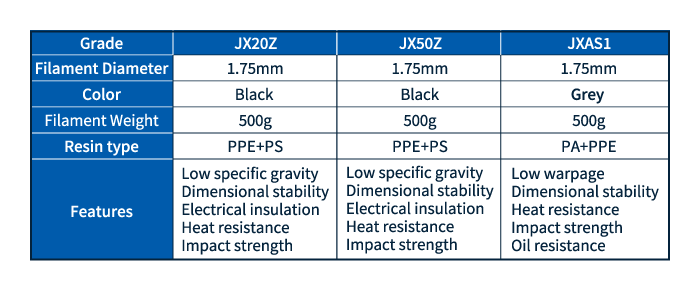

Key Features

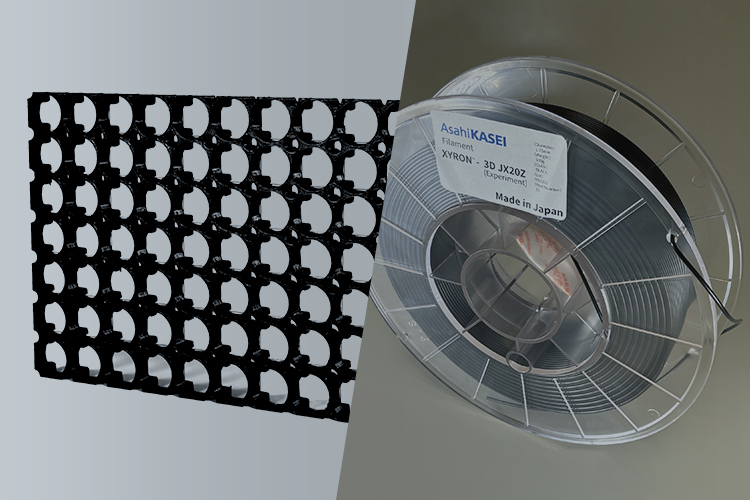

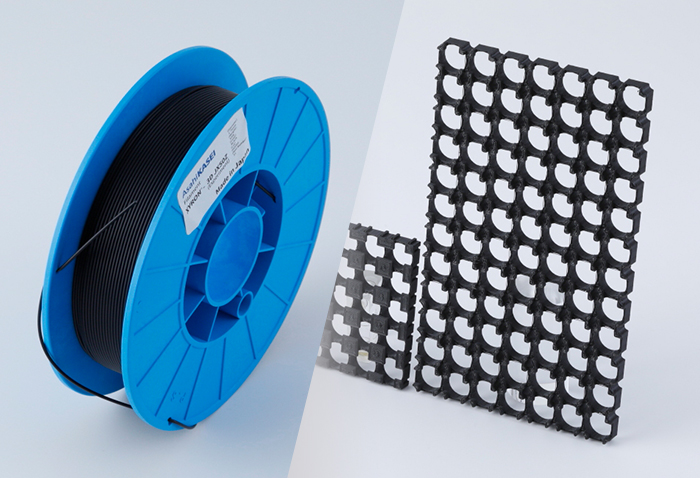

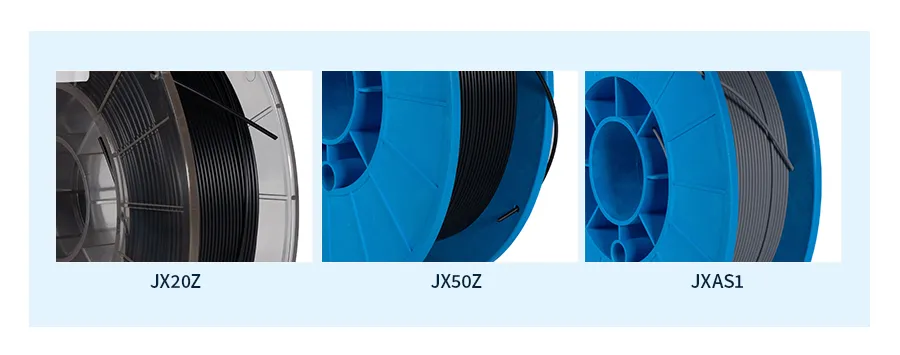

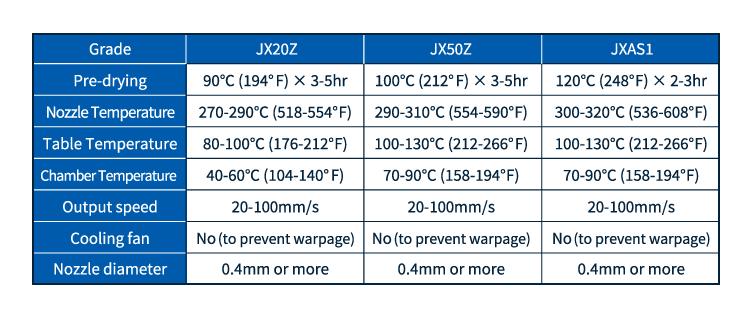

Asahi Kasei has developed a filament for 3D printers using XYRON™, a modified PPE resin that is used in a wide range of applications due to its unique properties. Filaments for 3D printers using modified PPE resin XYRON™ have the following features.

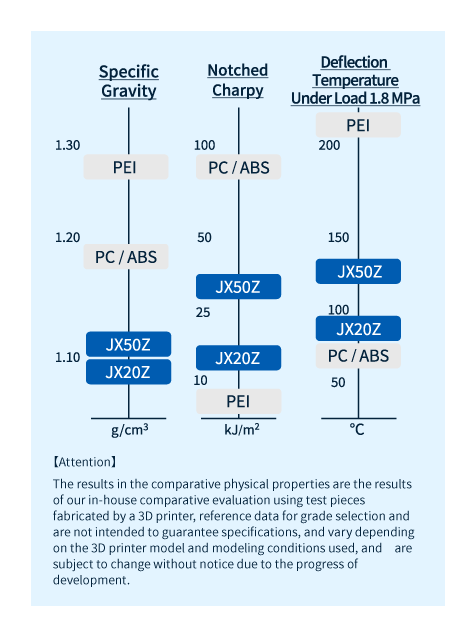

- Low specific gravity, which contributes to weight saving and reduction of material usage

- Excellent dimensional stability

- Excellent electrical properties and insulation properties

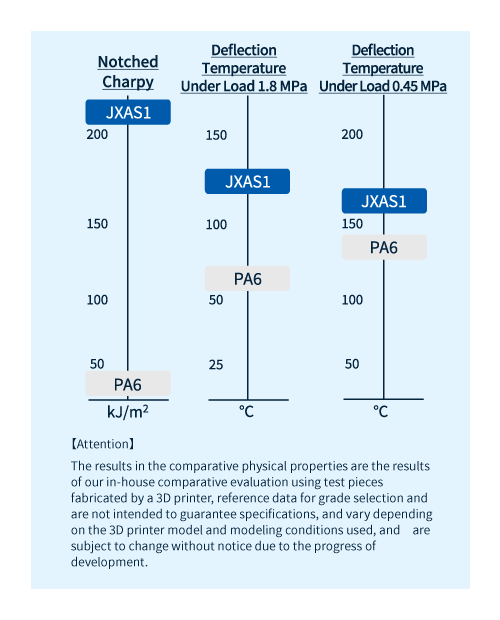

- Excellent heat resistance

- Excellent impact resistance

These characteristics are expected to provide performance comparable to super engineering plastic filaments, depending on how they are used.

*XYRON™ is Asahi Kasei's family of modified PPE (modified polyphenylene ether or mPPE) resin products. Modified PPE resins are polymer alloys formed by compounding PPE resins with other types of resin. PPE resins are engineering plastics featuring excellent heat resistance, flame retardance, electrical properties, and dimensional stability, with low water absorption and low specific gravity. Asahi Kasei offers a lineup of various polymer alloy products, including PPE+PS, PA+PPE, PP+PPE, and PPS+PPE.