High-performance grades by alloying super engineering plastics with PPE

Technologies and Products

For inquiries regarding SDS and various chemical substance investigations, please make your request through your purchasing route, such as via a trading company.

We appreciate your understanding and cooperation.

2025.12.12

Technologies and Products

In electrical equipment such as bus ducts and busways, designers must balance insulation performance, flame retardancy, and weight reduction. Material choice directly affects design freedom, manufacturability, and total system cost.

Asahi Kasei’s modified PPE resin, XYRON™, is an engineering plastic that meets these performance demands in profile extrusion, even for complex cross-sections. The following overview explains profile extrusion and highlights the key features and advantages of using XYRON™ for extruded profiles.

This is a molding processing method that extrudes molten resin directly from the extruder die to continuously produce long products with complex cross sections of a fixed shape.In addition to simple shapes such as round tubes and plates, it is possible to continuously extrude cross sections with grooves, cavities, steps, etc. in a fixed shape.

This technology is widely used for parts that require long lengths and complex shapes, such as electrical covers, cable ducts, data center busways, insulating rails, furniture, and housing components.

Companies use profile extrusion for components such as electrical covers, cable ducts, insulating rails, architectural trim, furniture components, and other elongated parts that require consistent properties along their length.

XYRON™ is Asahi Kasei’s proprietary modified polyphenylene ether (m-PPE) resin. Starting with an amorphous PPE base, the material is alloyed with other polymers and additives to tailor heat resistance, mechanical performance, processability, and environmental durability for a wide range of applications.

| Features | Description |

|---|---|

| 1. Excellent Heat Resistance | Grades are available with glass transition temperatures from 90 to 220 °C, allowing parts to maintain shape and function in demanding thermal environments. |

| 2. Flame-Retardant and Halogen-Free | High flame retardancy is achieved without halogenated additives, supporting safer and more environmentally responsible product designs. |

| 3. High Electrical Insulation | The PPE structure provides high volume resistivity and outstanding electrical insulation performance. |

| 4. Dimensional Stability and Hydrolysis Resistance | Low water absorption minimizes swelling or warping in humid environments. The material also resists hydrolysis under elevated temperature and humidity. |

| 5. Lightweight | PPE has inherently low density, enabling lightweight design when replacing metals or higher-density engineering plastics such as PC. |

| 6. Stable Processing Behavior | As an amorphous resin, XYRON™ allows consistent melt-temperature control and stable extrusion behavior. |

Flame-retardant, halogen-free materials suitable for profile extrusion are limited. While PVC is often considered, its higher density and halogen content can create design and environmental trade-offs.

XYRON™, being an amorphous resin, provides stable viscosity control and smooth extrusion processing. While amorphous polycarbonate (PC) is another potential candidate, PC typically suffers from poor hydrolysis resistance. XYRON™ delivers superior performance in humid and high-temperature environments, supporting long-term reliability for both indoor and outdoor use.

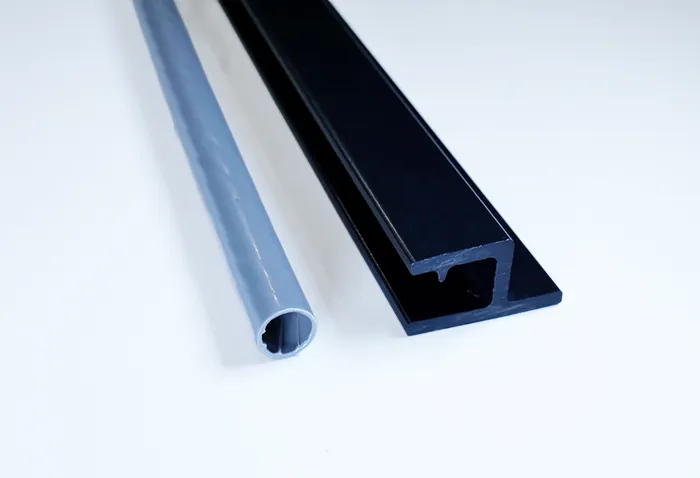

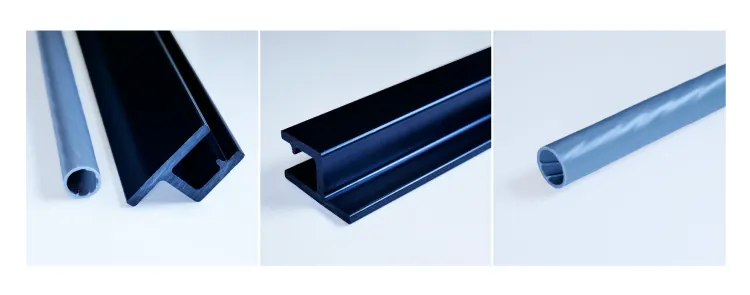

XYRON™ Extrusion Profiles Sample Cross-Section

XYRON™ Extrusion Profiles Sample Cross-Section

XYRON™ can produce complex profile geometries with excellent dimensional consistency. The material is compatible with standard extrusion equipment, allowing manufacturers to run trials on existing lines without significant changes to tooling or process setup.

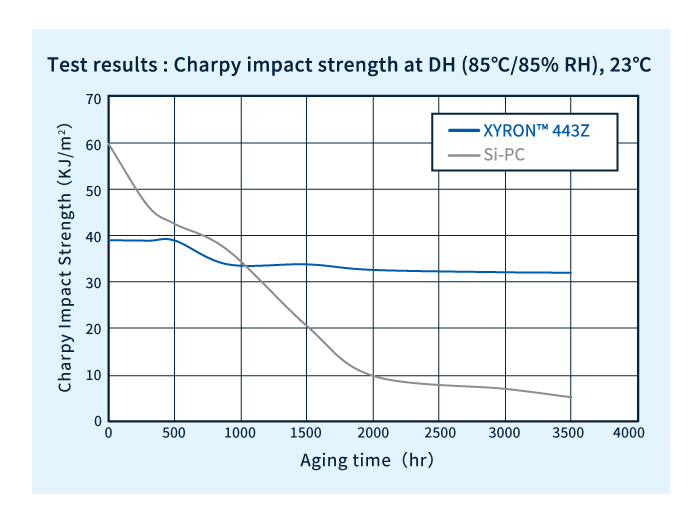

Performance Comparison with Polycarbonate (PC)

In accelerated aging tests at 85 °C and 85 percent relative humidity for 1,000 hours, XYRON™ shows significantly less appearance change and mechanical degradation than PC. This difference is due to XYRON™’s strong resistance to hydrolysis and moisture-related property loss.

Comparison test results with polycarbonate

Comparison test results with polycarbonate

高温高湿下(85 ℃/85%RH/1,000h)での物性保持率を比較するとザイロン™は加水分解による外観変化・強度低下が小さくなります。

XYRON™ is well-suited for profile-extruded components where electrical insulation, flame retardancy, and dimensional stability are critical. Potential applications include:

Using XYRON™ enables designers to meet required safety and performance standards while also achieving weight reduction and long-term durability.

→ Click here for “Materials for Electrical Insulation in High-Temperature Environments XYRON™ T series“

Profile extrusion provides design flexibility for long, complex components in the electrical and construction industries. XYRON™ supports this manufacturing method through its amorphous structure, halogen-free flame retardancy, low density, and resistance to heat and humidity. These characteristics open opportunities for high-performance extruded profiles that are difficult to achieve with conventional materials.

For more information on XYRON™ in profile extrusion, or to discuss prototyping or joint development, please get in touch with us through the form below.

If you would like more detailed information, please contact us using the form below.

If you would like more detailed information, please contact us using the form below.

Please feel free to contact us with any questions about our products or technologies or to request samples.

We will introduce Asahi Kasei 's engineering plastic products and technologies in more detail.

We regularly deliver product and industry information to help you gather information.