製品

比重が小さく、難燃性、電気特性、寸法安定性に優れます。太陽光発電、EV、通信機器等に採用されています。

国連の持続可能な開発目標をはじめとする世界的な水の安全保障の取り組みにより、水道等のインフラや居住設備を提供する建築業界・住宅設備メーカーでは飲料水の安全性の向上、二酸化炭素排出量の削減、水資源の持続的な管理を求められています。特に、飲料水の安全性の観点では、従来より用いられてきた真鍮・銅といった金属から鉛やその他有害な溶出物の混入を防ぐため、世界各地で水に接触する材料の規制が厳しくなっています。

また、新興国を中心とする、住宅・ビル建設・インフラ整備に伴い、飲料水システムの需要が拡大し続けています。結果、建築業界・住宅設備メーカーは世界各地の規制をクリアした材料を状況に応じて使いこなしながら、複雑化するサプライチェーンに対応するという難しい課題を抱えています。

こうした環境の中、我々の日々の生活ではなかなか目に見えない部分、例えば水道メーター、蛇口、シャワー、配管・パイプ、継手、フィルターのような飲料水と接触する部品では、金属からプラスチックに置き換えた製品が増えています。

有毒な溶出物・汚染を防止する目的だけでなく、機械的性能・耐薬品性を満たしながらも錆びないという樹脂の特徴を活かした製品の長寿命化や、軽量化による輸送時の環境負荷低減とコスト削減等がメリットです。

旭化成では、飲料水規格に適合したお客様の製品作りをサポートするために、欧米の飲料水規格 (NSF、KTW-BWGL、ACS、WRAS等) に準拠した樹脂材料を取り揃えています。

飲料水接触用途の材料として、旭化成の変性PPE樹脂 ザイロン™Wシリーズをご提案します。

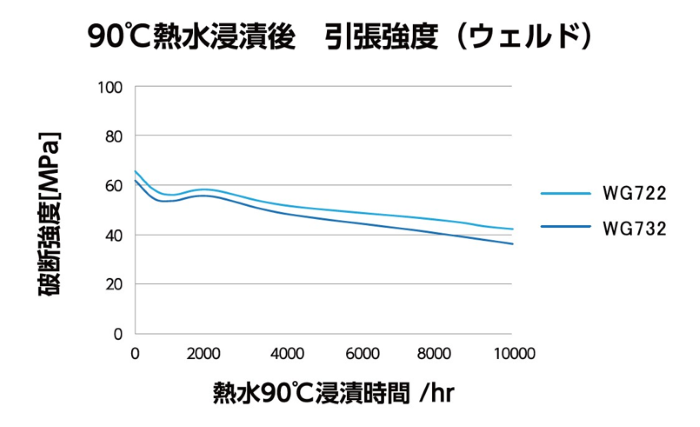

ザイロン™ Wシリーズは、欧米の各種飲料水認証を取得しており、溶出成分が少ない樹脂材料です。各規格の温水環境にも準拠しており、ポンプ部品、混合栓、軟水化装置、浄水器など幅広い給排水設備・製品にご活用いただけます。

機械強度、耐加水分解性、低吸水性、耐酸・アルカリ性に優れることから長寿命な製品作りに貢献します。また、寸法精度に優れ、成形性も良いことから、効率的な生産が可能となり、コスト削減に貢献します。

| 飲料水認証 | 非強化 | 強化 | |

|---|---|---|---|

| NSF-61(米) | W5000 | WG720 | WG731 |

| NSF-61(米) | W5002 | WG722 | WG732 |

| KTW-BWGL(独) | |||

| ACS(仏) | |||

| WRAS(英) | |||

| 項目 | 単位 | 試験法 | 条件 | XYRON™ WG722 |

XYRON™ WG731 |

XYRON™ WG732 |

|---|---|---|---|---|---|---|

| 比重 | ‐ | ISO 1183 | 23℃ | 1.20 | 1.28 | 1.28 |

| 吸水率 | % | ISO 62 | 24Hr水中 | 0.06 | 0.06 | 0.06 |

| 荷重たわみ温度 | ℃ | ISO 75-1 | 1.80MPa | 144 | 135 | 144 |

| 引張強度 | MPa | ISO 527 | 23℃/50RH | 121 | 125 | 140 |

| ウェルド強度 | MPa | 旭化成法 | 23℃/50RH | 65 | 47 | 62 |

| 曲げ弾性率 | MPa | ISO 178 | 23℃/50RH | 6900 | 9300 | 8900 |

| シャルピー衝撃強度 | kJ/㎡ | ISO 179 | 23℃/50RH | 12 | 10 | 12 |

| 備考 | GF20% | GF30% | GF30% | |||

旭化成のポリアミド (PA) 樹脂 レオナ™は、ガラス繊維により強化された、強度に優れる材料を提供しており、高い荷重や水圧がかかる製品に適用が可能です。

旭化成のエンプラ・樹脂材料を用いたお客様の製品設計に対して、樹脂CAEによる各種シミュレーションをご提供しています。例えば、金属から樹脂への置き換えを図る場合、必要なスペックをクリアするために製品形状の最適化等が必要となります。旭化成は各樹脂の特徴を考慮したシミュレーション・最適化を行うことで、お客様のモノづくりを支援いたします。

For more information, please contact us using the links below.