製品

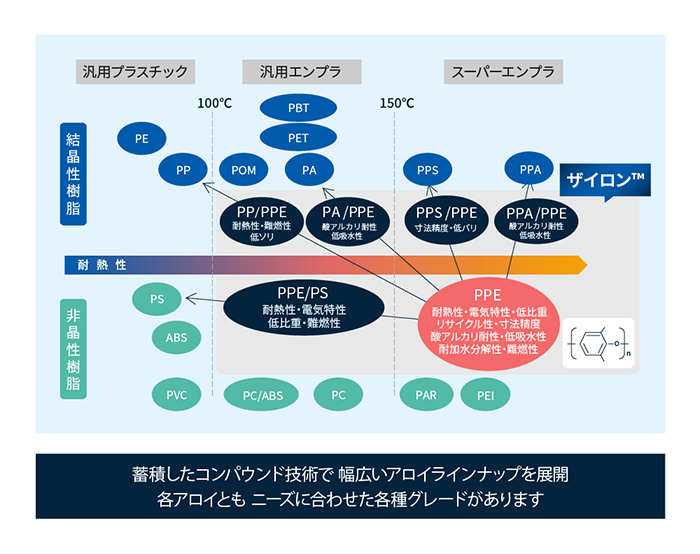

比重が小さく、難燃性、電気特性、寸法安定性に優れます。太陽光発電、EV、通信機器等に採用されています。

欧州を中心とした環境規制・排ガス規制の強化が進み、グローバルでCO2削減強化が進められる中、クルマの電動化、xEV化については、国や地域で規制や方針が異なります。これまでも自動車に対するCO2排出規制は厳しく設定されてきましたが、今後のさらなる排出規制強化をエンジンの効率向上だけで対応することは困難になってきています。

そこで、自動車メーカー各社は電動化技術の開発と実装により、燃費改善を図っています。

EV(電気自動車・電動車)のバッテリーにおける1番の課題は、そのエネルギー密度を高めることです。エネルギー密度を高めることにより、スペース・重量を損なうことなく、車の航続距離を延ばすことができます。

旭化成は、高機能なエンジニアリングプラスチックで車載バッテリー20年以上の実績があり、お客様のモノづくりを支援します。

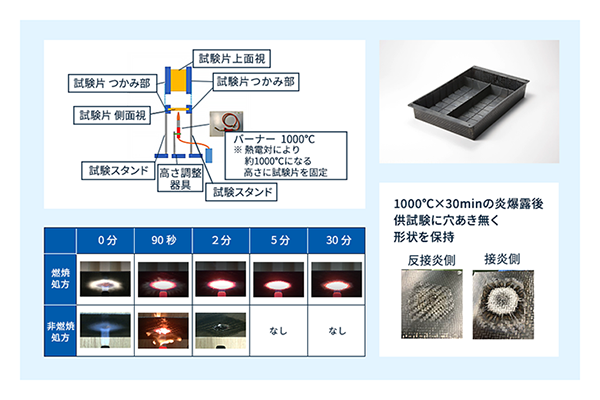

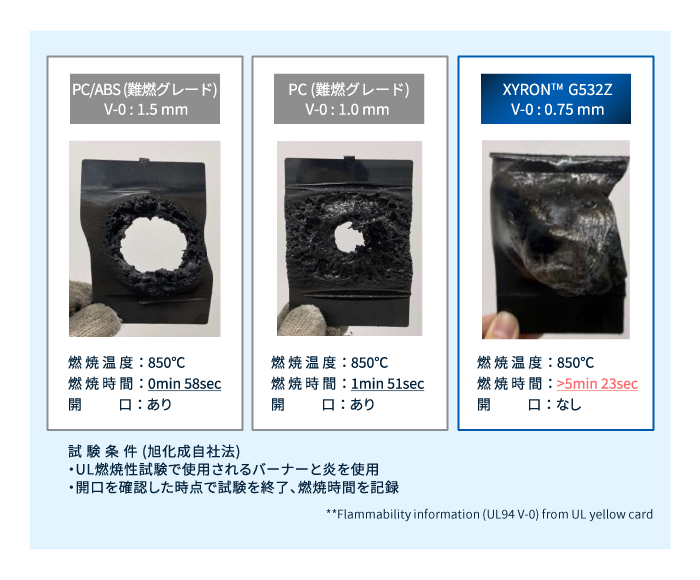

PPEは酸素指数 (燃えるために必要な酸素量)が高く、難燃化しやすい樹脂です。 ザイロン™は、優れた難燃性を有するグレードを多数ラインナップしています。下記図では、ULの燃焼性試験で使用されるバーナーと炎を使用し、燃焼性試験を実施しました。独自条件において、ザイロン™の難燃性の高さが確認できました。

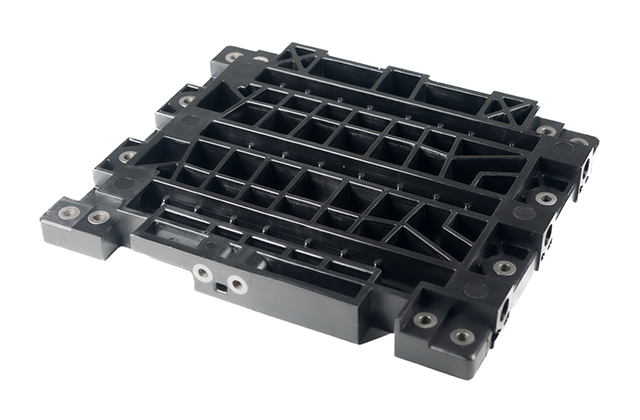

バッテリーのセル間に使用する絶縁部品であるセル間スペーサーには、耐トラッキング性、耐加水分解性、耐酸・アルカリ性、長期物性の安定に優れたザイロン™ 340Zと、これらの特徴に加えてさらに耐油・耐薬品性を有するPP/PPEアロイ ザイロン™ TFシリーズの活用をご提案します。

薄肉成形性が良好で、省スペース・軽量化に貢献します。さらに、クリープ特性、難燃性(ノンハロゲン)に優れ、車両安全にも寄与します。

高圧大電流が流れる導体の絶縁保護カバーに対して、軽量化・寸法安定性を重視する場合には、薄肉成形性と絶縁性、耐熱性を備える、ザイロン™ 440Z, 443Zをご提案します。

取り扱い性が容易となる、耐油性を有するザイロン™ Tシリーズもございます。

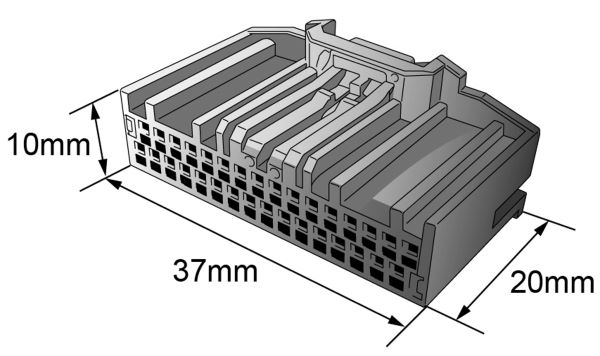

ザイロン™ 644Zは、車載バッテリー周辺のコネクターにご使用いただいています。

LV214やUSCAR等の厳格さが求められる自動車OEM規格に適合するためには、樹脂材料にも信頼性が求められます。

ザイロン™ 644Zは優れた難燃性(UL 94 V-0、5VA)、長期特性(UL746B RTI 125℃)、耐トラッキング性(CTI PLC=2)、耐候性(UL746C f1)等の特徴を有しています。

燃料電池を構成するスタック周辺部品には、ザイロン™500Hをご提案します。

樹脂からの溶出性(イオン、オリゴマー等)が少なく、耐熱水性、耐酸性に優れ、長期間浸漬しても物性がほとんど低下しません。

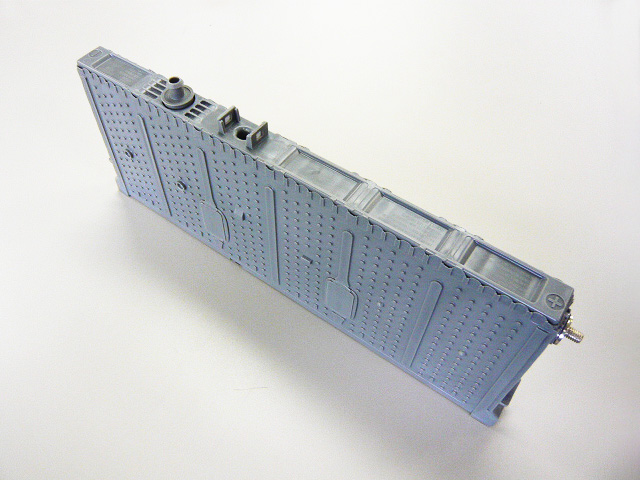

NiMH電槽部品向けのザイロン™⾮難燃グレードは、従来素材(⾦属)と⽐べ軽量化を達成するとともに、電池ケースとして必要な性能を備えた素材として、開発されました。

軽量(低⽐重)かつ、耐アルカリ性、ガスバリア性、耐⾦属劣化性に優れています。

こちらは旭化成グループの環境貢献製品として、製品を使用する段階でCO2削減に貢献しています。

ポリアミド樹脂レオナ™ は強度・剛性、耐熱性、耐薬品性に優れたエンジニアリングプラスチックです。

ガラス繊維(GF)のような充填材(フィラー)によって強化することで、強度・剛性、耐久性、寸法安定性を向上することができます。

バッテリーモジュールの両端面で、積層しているバッテリーセルを押付・固定するエンドプレート向けには、成形加工性・強度・靭性・電気特性(CTI)・耐熱性を有するグレードレオナ™SNシリーズをご提案します。

高圧大電流が流れる導体の絶縁保護カバーに対して、高強度・長期特性(RTI取得)を求める場合には、薄肉成形性、絶縁破壊強度、耐トラッキング性 (CTI 600V)、難燃性 (UL 94 V-0)、長期耐熱特性 (RTI)に優れる、レオナ™ SN11Bをご提案します。

難燃PA66はE&Eや自動車を中心にかつてより使用用途の幅を広げています。近年、世界で環境負荷削減や労働者の安全性を重視する傾向が高まり、ハロゲンや赤燐不使用の要求が増えています。

そこで旭化成は環境・安全を考慮し、ハロゲンと赤燐を含まない難燃剤を使用する新しいレオナ™SNグレードの開発に着手し、その完成に至りました。

サンフォース®は軽量、断熱性という発泡体ならではの性能に加えて、難燃性(UL-94 V-0)、寸法精度、薄肉成形などの、従来の発泡体を超えた機能を併せ持ったm-PPE(変性ポリフェニレンエーテル)のザイロン™をベースとした発泡体です。

サンフォース®は発泡させている分、樹脂の使用量が少ないため樹脂部を伝わる「伝導」が小さく、高い断熱性を有しています。

変性PPE発泡ビーズのサンフォース®は、優れた断熱性で、EV向けバッテリーの熱マネジメントに貢献します。

バッテリーが低温になると、その出力が大きく低下する事が知られています。 SunForce™

電気自動車や高出力のハイブリッド車では、セルの温度低下を防止するために、ヒーター等で加熱して適温に維持する工夫をされている車両もあります。

このような課題に対し、サンフォース®でバッテリーを断熱することにより停止時のバッテリーの放熱を防止し、数時間の停車ではヒーターで加熱することなく、バッテリーの高出力を引き出すことが可能です。

また、ヒーター使用時もサンフォース®の断熱効果により外部への放熱ロスを極小化することが可能です。

さらに、運転中にセルを冷却するための電力を節約できます。サンフォース®で筐体を通じた外部からの熱影響を減らすことで、熱交換効率を上げバッテリーの性能を最大限に活かします。

「レンセン™」は、連続ガラス繊維の織物とポリアミド66(PA66)のフィルムを積層させた旭化成の連続繊維強化複合材料です。

金属に対しても同等以上の引張強度と衝撃吸収性を有する事から、衝突安全性の向上や軽量化効果を得ることが期待できます。