Product

A bead made by foaming modified PPE resin and have excellent flame resistance, low dielectric properties, dimensional accuracy.

For inquiries regarding SDS and various chemical substance investigations, please make your request through your purchasing route, such as via a trading company.

We appreciate your understanding and cooperation.

A drone is a general term for an aircraft that flies without a human onboard, operated remotely or autonomously. Drones are also called UAVs (Unmanned Aerial Vehicles) or unmanned aircraft. In recent years, their use has rapidly expanded in various fields such as industry, disaster prevention, agriculture, and logistics.

Materials for drone parts require not only lightweight properties but also high rigidity for stable flight and weather resistance against UV rays and humidity for outdoor use. Additionally, for drone blades, fixed-wing drone wings, and housings, further weight reduction through thinning, cost reduction for mass production, and improved heat and weather resistance are also required.

At Asahi Kasei, we propose the engineering plastic foam “SunForce™” as a material for drone parts such as blades, wings, and housings.

SunForce™ is a bead foam made from Asahi Kasei’s modified PPE resin “XYRON™.” Like general-purpose foams such as expanded polystyrene (EPS) and expanded polypropylene (EPP), it can be processed using similar molding processes.

In addition to the typical foam properties of lightweight and thermal insulation, it also offers high heat resistance and high rigidity unique to engineering plastics.

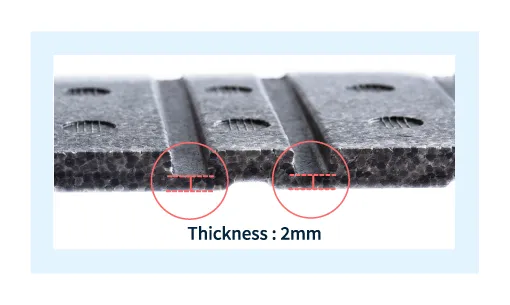

Furthermore, since SunForce™ uses small-diameter beads, it is suitable for thin-walled and complex-shaped molding, enabling efficient production of components.

For more details on the advantages of SunForce™, including physical property data, please refer to the download slides.

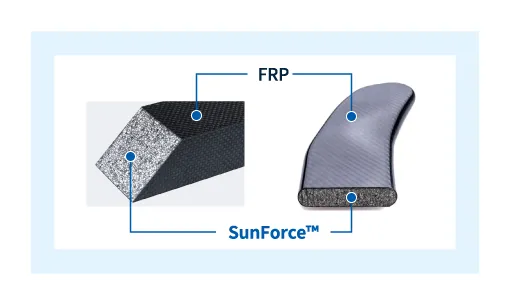

Recently, to achieve lighter and more rigid drone parts, the use of composite materials that laminate fiber-reinforced plastics (FRP) such as carbon fiber (CF) or glass fiber (GF) with foams is expanding.

Below are the features of SunForce™ as a core material for FRP composites.

As an FRP core material, SunForce™ has higher heat resistance than EPS or EPP, making it compatible with high-temperature composite molding with prepregs containing carbon or glass fibers. It is suitable for major composite molding processes such as “autoclave method,” “PCM (Prepreg Compression Molding) method,” and “RTM (Resin Transfer Molding) method,” with increasing adoption in PCM processes.

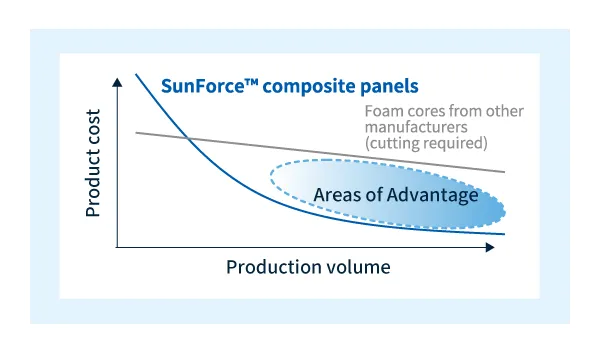

Unlike board-type foams such as PMI (polymethacrylimide), SunForce™ does not require cutting processes, achieving both mass productivity and cost reduction, and bringing innovation to FRP composite molding processes.

Thanks to these features, FRP composites using SunForce™ foam core enable efficient mass production of multicopter drone blades and fixed-wing drone wings.

For further details or sample requests, please contact us via the form on our website.

Please feel free to contact us with any questions about our products or technologies or to request samples.

We will introduce Asahi Kasei 's engineering plastic products and technologies in more detail.

We regularly deliver product and industry information to help you gather information.