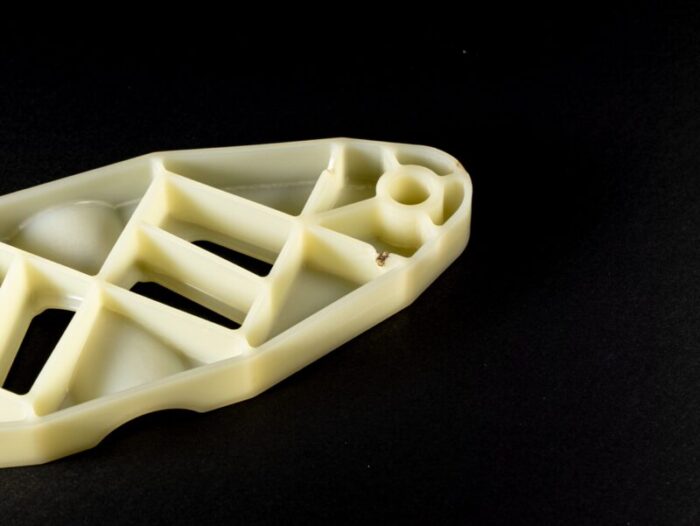

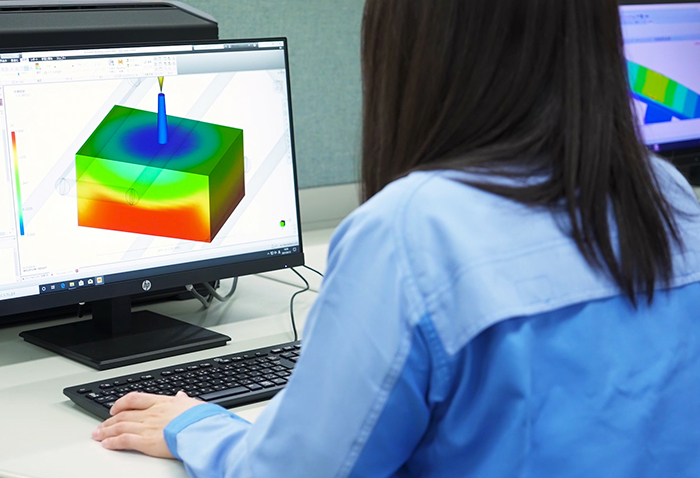

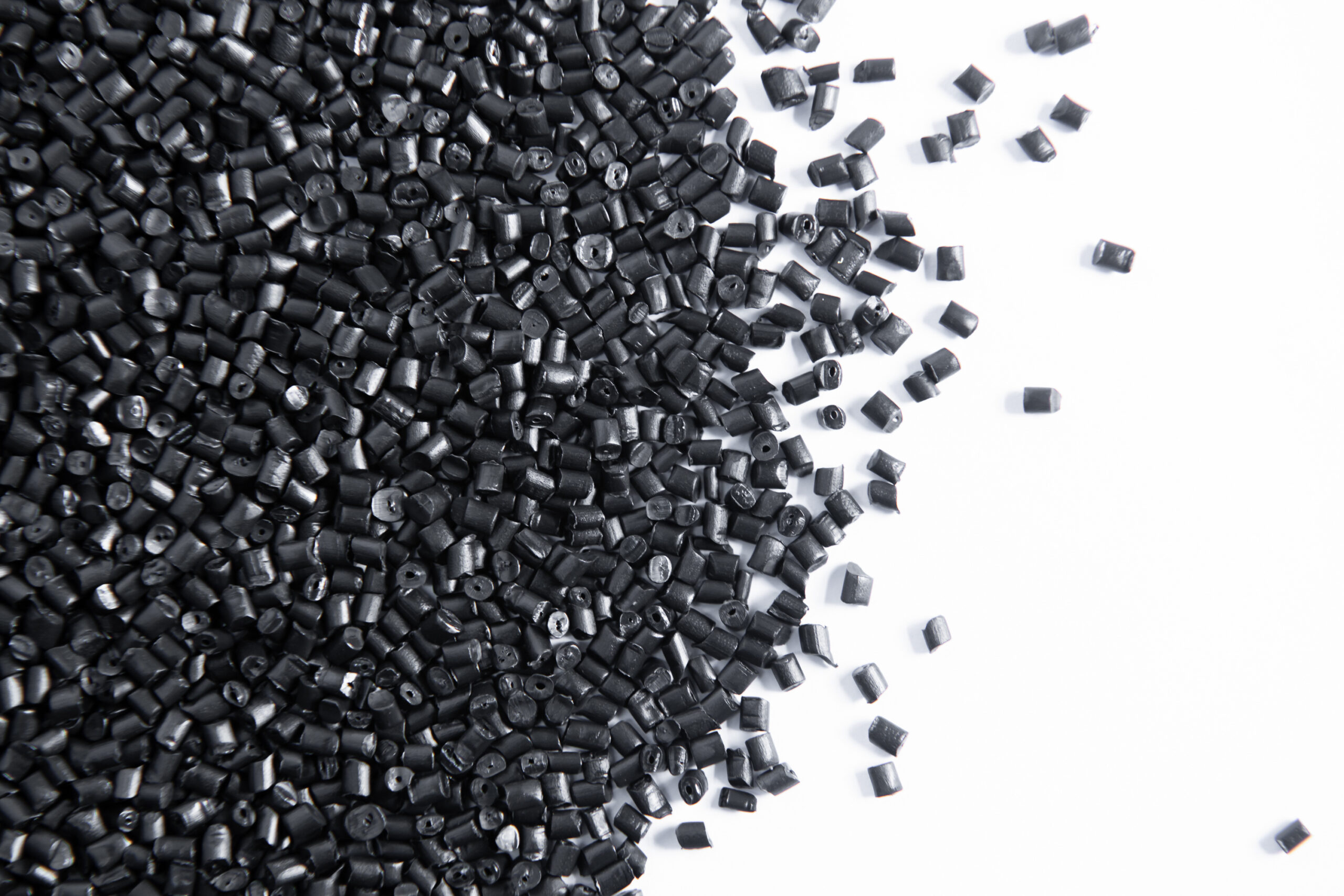

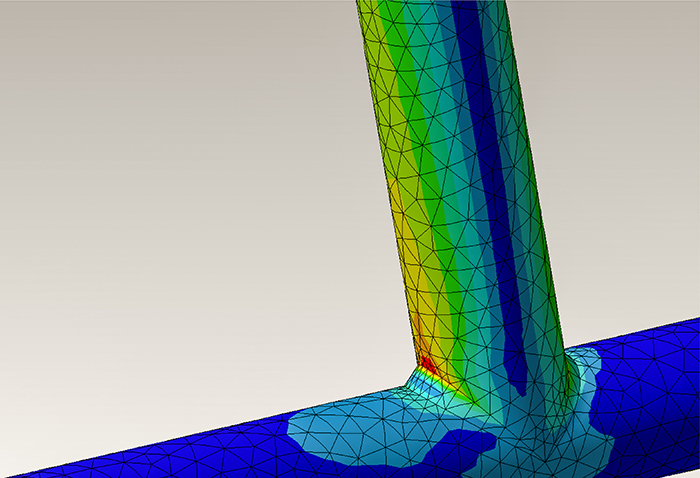

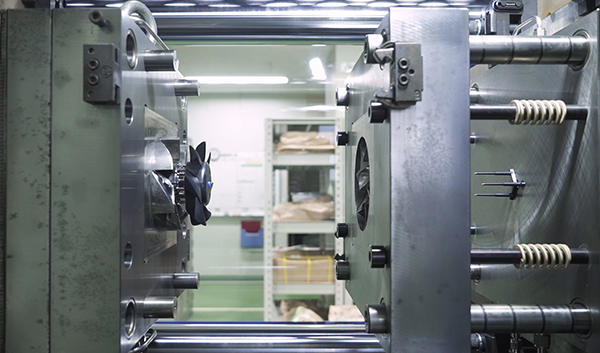

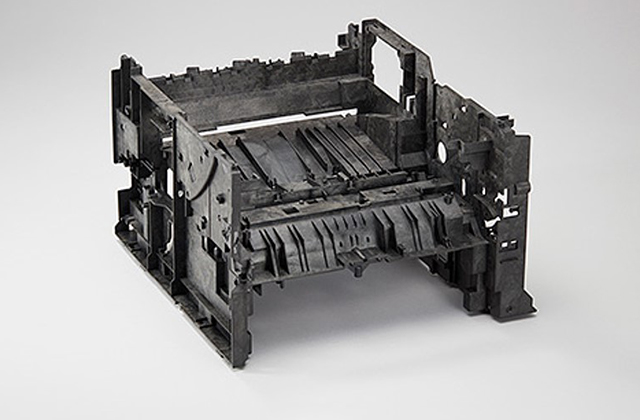

Injection molding analysis can predict the orientation of fiber reinforcement (fibrous filler) in injection molding. This article explains what fiber reinforcement orientation is in injection molding and the importance of understanding the orientation.