- TOP

- Fundamentals of CAE

- Part 2 Key points of plastic CAE

Series: Fundamentals of CAE Analysis for Plastic Product Design

Part 2 Key points of plastic CAE

We will explain the differences in the material properties of plastics and metals in an easy-to-understand manner, and introduce the points to be considered in CAE analysis of plastics.

Contents

| 1. What is plastic? |

| 2. Difference between plastic and metal |

| 3. Notes on plastic CAE analysis |

| 4. Summary |

What is plastic?

Plastic is an English word that literally translates to “plasticity”. It is a property that it easily deforms when a force is applied and does not return to its original shape even when the applied force is removed.

ISO 472 (1988) defines plastics as "materials which contain high polymers as essential constituents and which can be given shape by flow at some stage of processing into the finished product". In other words, plastic molding can be said to be "a processing method in which polymer materials are given fluidity by means of heat, etc., given to them in almost the same shape as the finished product, and then solidified and taken out." It is similar to metal casting in the sense that it is melted, shaped, solidified and taken out. However, plastics have different properties and characteristics from metals.

It was mentioned in the first issue that CAE was developed for use in the design of aircraft and other metallic materials.In order to use CAE with plastics, it is necessary to know the material properties of plastics.

■ Types of plastic

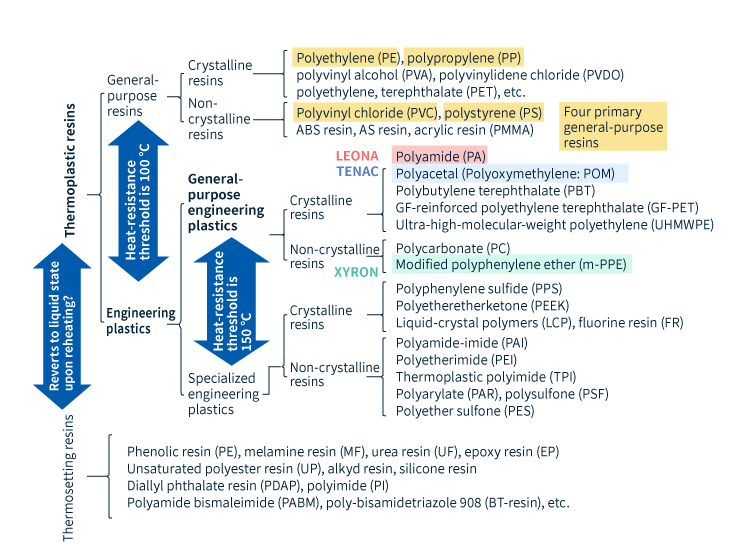

There are many types of plastics, but they can be roughly divided into “thermosetting plastics” and “thermoplastics”.

[Thermosetting plastic]

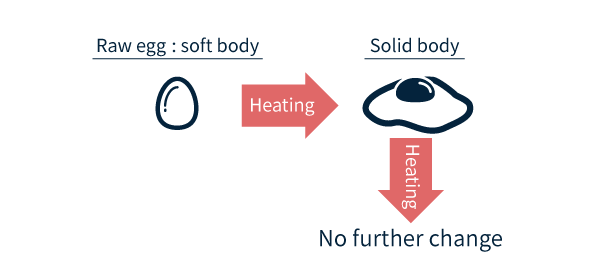

Plastics that harden when heated are called thermosetting plastics.

Typical thermosetting plastics include epoxy (EP), phenol (PF), melamine (MF), silicone (SI), and polyurethane (PUR). Heat causes a chemical change and hardens. Once hardened, it does not soften even if it is reheated, and has excellent heat resistance. In addition, because the molecules are cured by forming a cross-linked structure, they also have excellent mechanical properties and chemical resistance.

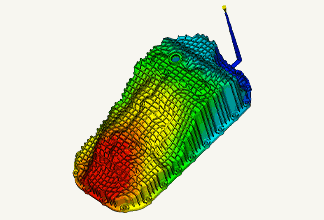

Figure 1 Thermosetting plastic (egg shape)

Figure 1 Thermosetting plastic (egg shape)

However, since the molding cycle is long and post-processing such as deburring is required, mass production is not very good. It accounts for about 10% of the domestic production volume, and because it is difficult to recycle, its use in products is limited.

[Thermoplastic plastic]

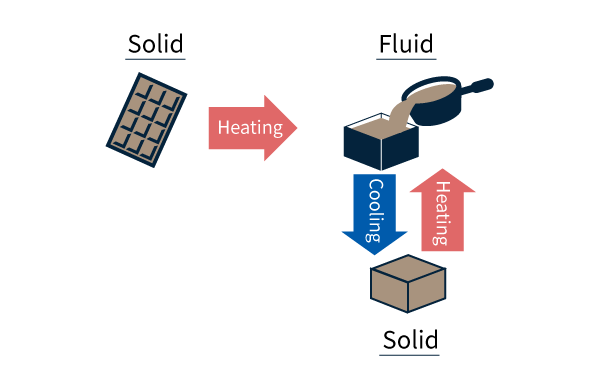

Thermoplastics are plastics that soften when heated.

Thermoplastics are commonly used in plastic molding. Injection molding allows for continuous, low-cost mass production. They can be recycled because they soften when reheated.

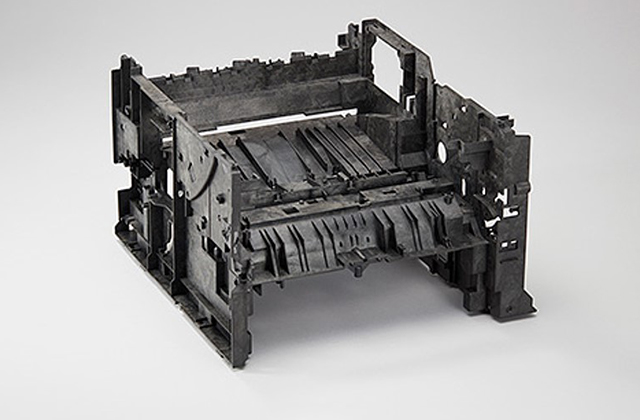

Figure 2 Thermoplastic plastic (chocolate mold)

Figure 2 Thermoplastic plastic (chocolate mold)

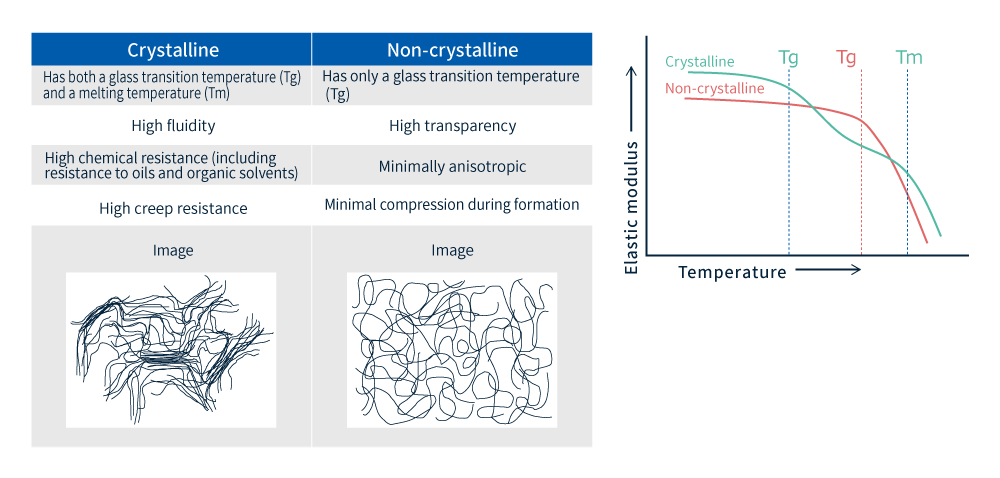

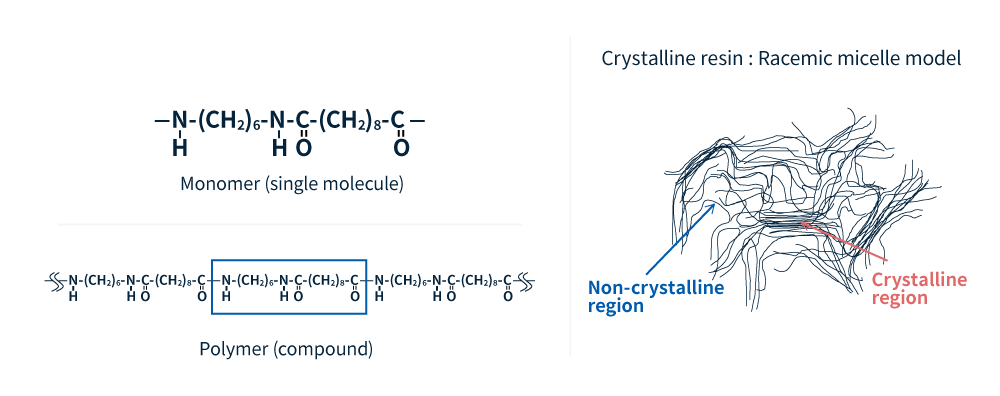

Thermoplastics are further divided into crystalline plastics and amorphous plastics according to the difference in molecular structure.

Crystalline plastics have a structure in which parts of a polymer are arranged neatly, and they have a crystalline part, and are made up of a crystalline part and an amorphous part. On the other hand, amorphous plastics do not have a crystalline structure (Fig. 3 image).

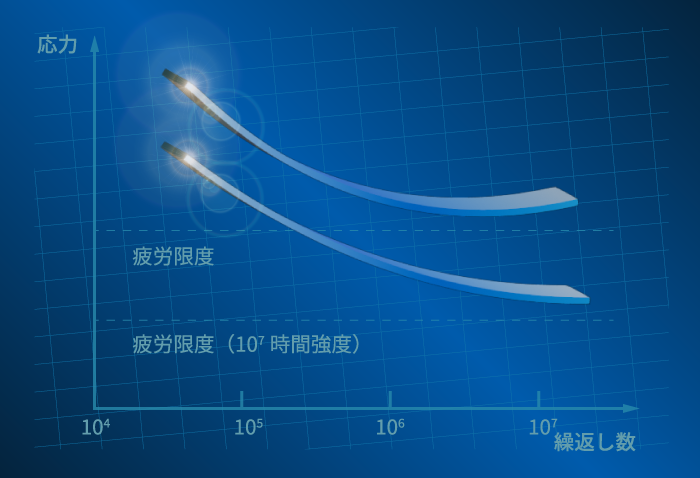

Crystalline plastics have a glass transition temperature (Tg) and a melting point (Tm), while amorphous plastics only have a glass transition temperature (Tg). Amorphous plastics soften rapidly above the glass transition temperature, while crystalline plastics can maintain their hardness. However, crystalline plastics also soften rapidly when they exceed their melting point (Fig. 3, right).

Crystalline plastics have dense crystals that diffuse light, resulting in low transparency and high chemical resistance and fatigue (creep) resistance. Amorphous plastics tend to be highly transparent and easy to paint and adhere.

Fig. 3 Differences between crystalline and amorphous plastics

Fig. 3 Differences between crystalline and amorphous plastics

Thermoplastics that are often used for molding are commonly referred to as 'general purpose plastics'. Typical examples are polypropylene (PP), polyethylene (PE), polystyrene (PS), and acrylonitrile-butadiene-styrene (ABS). Among these, PP and PE are classified as crystalline resins, while PS and ABS are classified as amorphous resins.

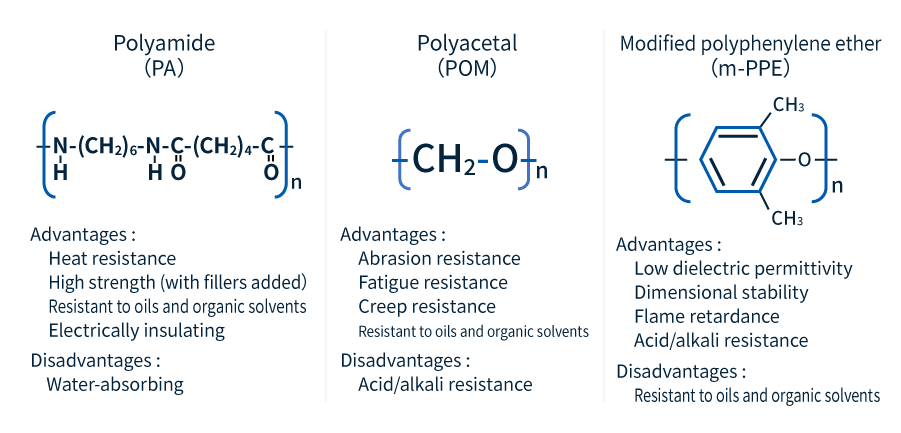

heat resistance of 100°C or higher, strength of 49 MPa (500 kgf/cm2) or higher, and flexural modulus of 2.4 GPa (24,500 kgf/cm2) or higher are called "engineering engineering plastics." When designing products, engineering plastics plastics are selected when general-purpose plastics cannot meet requirements such as strength and heat resistance.

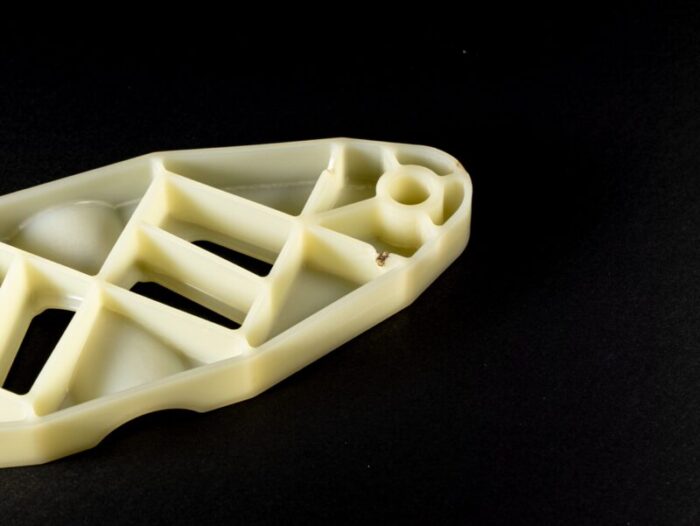

Typical examples include polyamide (PA), polyoxymethylene (POM), and modified polyphenylene ether (m-PPE). Figure 4 shows the structures and characteristics of PA, POM, and m-PPE from left to right. Among these, PA and POM are classified as crystalline plastics and m-PPE as amorphous plastics.

Figure 4 Characteristics of Asahi Kasei 's engineering plastics

Figure 4 Characteristics of Asahi Kasei 's engineering plastics

→ Learn about "Polyamide" in detail

→ Learn about "Polyacetal" in detail

→ Learn about "m-Polyphenylene ether" in detail

A high-performance resin with higher mechanical strength, chemical resistance, and heat resistance than engineering plastics. Super engineering plastic (super engineering plastics) called. Maintains mechanical performance even in high temperature environments of 150°C or higher. Typical examples include liquid crystal polymer (LCP) and polyphenylene sulfide (PPS).

Fig. 5 Plastic classification list

Fig. 5 Plastic classification list

In recent years, various plastics have been developed, including biomass plastics containing components derived from plants such as corn, and biodegradable plastics that are decomposed by microorganisms.

Difference between plastic and metal*

*From now on, "plastic" refers to thermoplastics.

■ Structure

The structure of a metal consists of a large number of atoms (Al, Fe, Cu, etc.) arranged in an orderly manner to form a crystal (Fig. 6). Free electrons with negative electric charge freely move around the atomic nucleus (positive ion), strongly bonding the atoms together. This is called a metallic bond.

Fig. 6 Image of metal structure

Fig. 6 Image of metal structure

On the other hand, plastics are in a polymerized state of monomers, each of which has different molecules covalently bonded to each other. This is called a polymer (polymer), and it is also called a molecular chain because the molecules are long connected like a chain. The inside of the plastic is in a state where this polymer is entangled, and it has various structures such as crystalline and amorphous parts. This difference in structure affects the melting point, physical properties, glass transition temperature, etc.

Fig. 7 Plastic structure image

Fig. 7 Plastic structure image

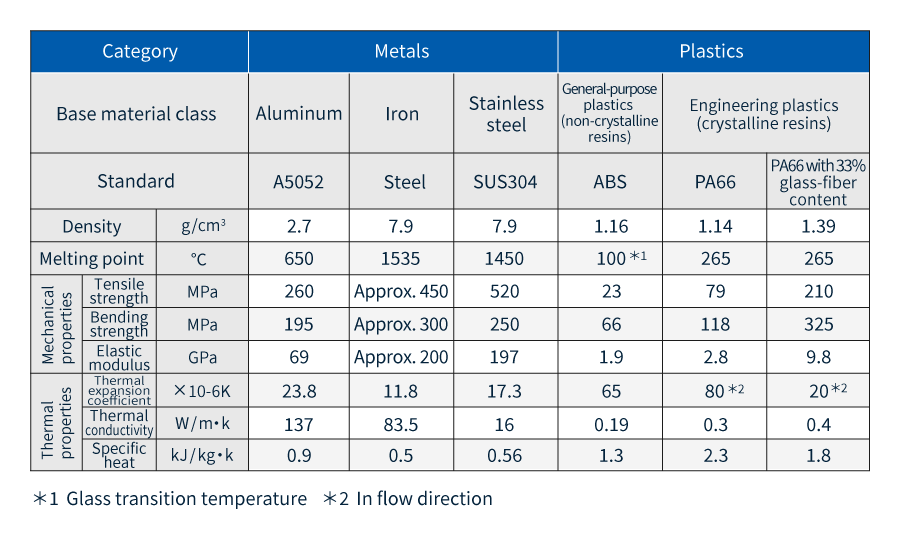

■ Physical properties

A comparison of the physical properties of plastics and metals is shown in the table below.

Fig. 8 Comparison of physical properties of plastic and metal

Fig. 8 Comparison of physical properties of plastic and metal

The first general characteristic of plastics is that they are lighter than metals. It is about 1/2 to 1/4 the weight of aluminum and 1/7 to 1/10 the weight of steel and copper. Therefore, by replacing metal with plastic, weight can be reduced.

There is an image that plastic is strength than metal, but depending on the grade and type, plastic may be stronger.However, the modulus of elasticity (difficulty in deformation) is higher in metal, and in a comparison of aluminum and Asahi Kasei 's polyamide resin LEONA™ 14G33 (polyamide 66, glass-fiber 33%), aluminum is seven times higher. I'm here.

Metal generally has a very high flash point and ignition point and is difficult to burn, but plastic burns at a lower temperature. On the other hand, plastics have very low thermal conductivity and high specific heat (the amount of heat required to raise the temperature of a substance) compared to metals, so it can be expected to have a heat insulating effect.

■ Temperature characteristics

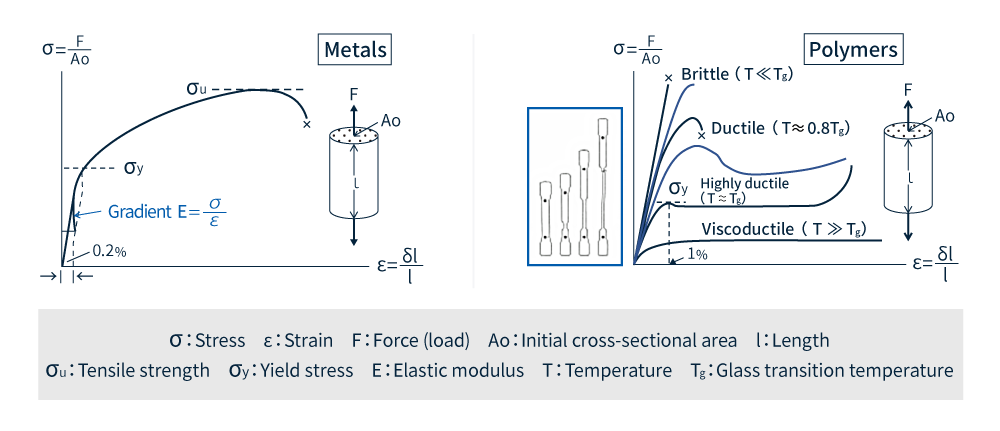

The melting point of general non-heat-resistant plastic (PP: polypropylene) is 170°C, while the melting point of metal (stainless steel) is 1450°C, which is incomparably different. Therefore, the material properties of plastics react sensitively to even a slight temperature rise.

Fig. 9 Comparison of stress (σ)-strain (ε) curves of metal (left) and plastic (right)

Fig. 9 Comparison of stress (σ)-strain (ε) curves of metal (left) and plastic (right)

Both metals and plastics have viscoelastic properties, but while metals only exhibit viscoelastic properties at temperatures of several hundred degrees or more, plastics are affected by even a 10 to 20 degree change in room temperature. This viscoelastic property affects things like tensile modulus and elongation at break. Viscoelastic properties will be discussed later.

The temperature characteristics are not proportional to temperature, but change rapidly around a specific temperature such as the glass transition temperature (Tg), as shown in Figure 9. At low temperatures, neither the crystalline part nor the amorphous part in the plastic can move and the flexibility is low (glass state). The temperature at which the amorphous part begins to move as the temperature rises is called the glass transition temperature (Tg). The melting point (Tm) is the temperature at which the temperature rises further and the crystal part can move freely. In other words, plastic loses flexibility and becomes brittle at low temperatures, and softens and loses its hardness at high temperatures. It is these temperature characteristics of plastics that cause cracks in plastic containers placed in the freezer and deformation in plastics heated in a microwave oven.

The coefficient of thermal expansion of plastics varies greatly depending on the material. Joining parts with different coefficients of expansion will result in different amounts of expansion and contraction when the temperature changes. The thermal stress caused by this causes deformation and cracks (Fig. 8).

Metal corrodes, but plastic deteriorates instead of corroding. Deterioration is accelerated by heat, so it is necessary to pay attention to the usage environment when designing plastic products.

■ Viscoelastic properties

・What is viscoelasticity?

Viscoelasticity is a property that combines elastic and viscous properties. Elasticity is a property in which force and deformation are proportional, just like rubber stretches when pulled and returns to its original shape when released. Viscosity is the property that the deformation progresses over time as if clay is stretched when pulled left and right. Viscoelastic plastics combine both properties, behaving like rubber under fast applied forces and like clay under slow applied forces.

As mentioned above, both plastics and metals have viscoelasticity, but metals only exhibit viscoelasticity at temperatures of several hundred degrees. Due to the temperature characteristics of plastics, it is necessary to fully evaluate phenomena that do not require much attention with metals. These are creep and stress relaxation.

<Creep>

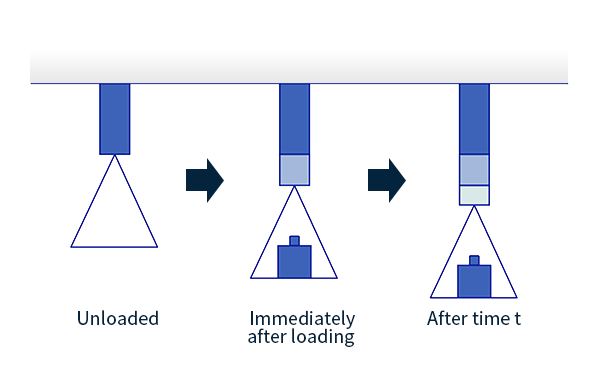

This is a phenomenon in which strain increases over time when stress is applied to an object for a long period of time.

Fig. 10 Image of creep phenomenon

Fig. 10 Image of creep phenomenon

As shown in Fig. 10, immediately after a weight is placed on a rod whose top is fixed, even after strain corresponding to that weight occurs, the strain gradually increases again over time. This is a deformation that emerges from the viscous nature. In case of high stress or in a high temperature environment, it may eventually lead to fracture.

Accurate evaluation of creep resistance is difficult, and it is easily affected by the environment, so it is desirable to design plastic products to avoid constant loads as much as possible.

<Stress relaxation>

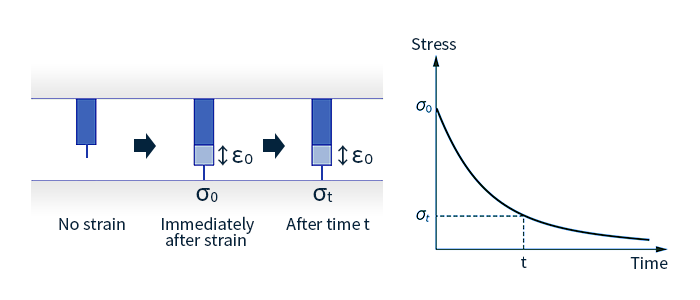

A phenomenon in which the stress decreases over time when a constant strain is applied to an object.

Fig. 11 Image of stress relaxation phenomenon

Fig. 11 Image of stress relaxation phenomenon

As shown in Fig. 11, when the lower side of a bar with a fixed top is hooked on the ground and a strain (ε 0) is applied, a high stress (σ 0) is generated initially, but this stress decreases with the passage of time. becomes smaller (σ t). There is no change in the amount of strain (ε 0) after hooking to the ground. Like creep, this is also caused by the viscoelastic properties of the material.

As a specific phenomenon, there is a phenomenon in which the axial force of screws and bolts and the pull-out force of press-fit parts decrease over time. When designing a product, it must be ensured that the minimum required load can be maintained over its service life.

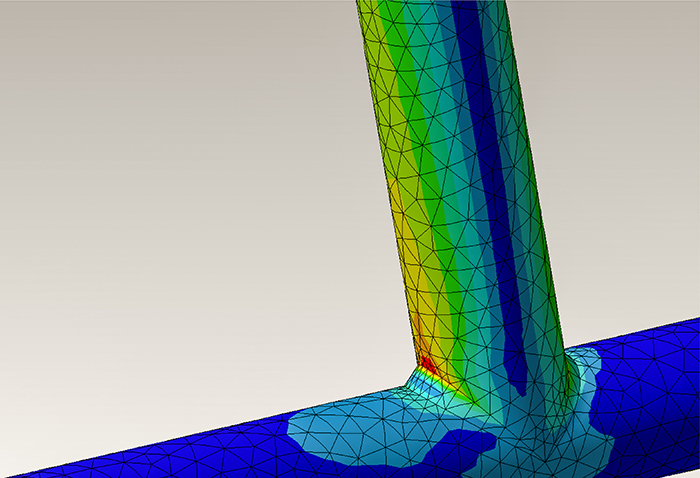

Notes on plastic CAE analysis

■ How to handle in analysis

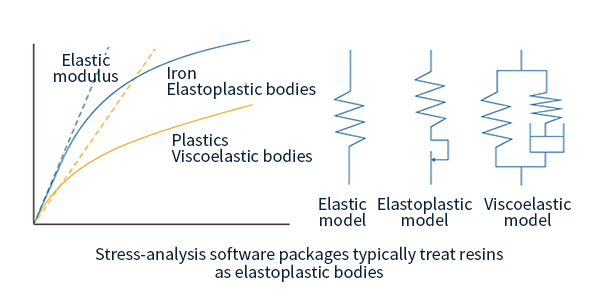

Plastic is a viscoelastic body, and the strain changes with time, but in normal structural analysis performed in CAE analysis, the effect of time is considered to be very small, so it is treated as an elastoplastic body.

Fig. 12 Rheological model diagram of metal and plastic

Fig. 12 Rheological model diagram of metal and plastic

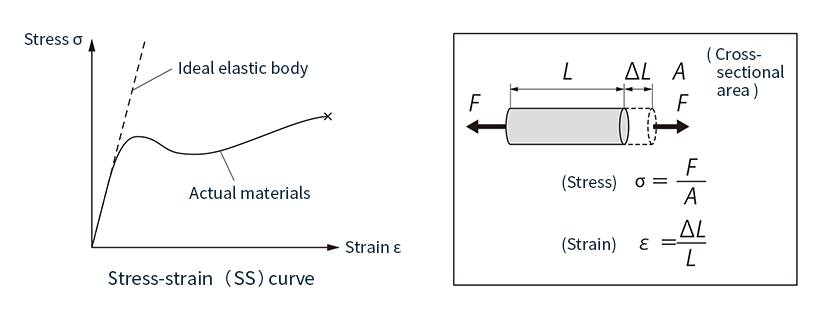

■ Material data to be used

It is important to know the mechanical properties of plastics when designing strength of products. For this purpose, the stress-strain curve (SS curve) is used. This is a graphical representation of the relationship between stress and strain that occurs when a force is applied to a material.

Fig. 13 Image of SS curve of plastic

Fig. 13 Image of SS curve of plastic

As shown in Figure 13, this graph has a complex nonlinear shape rather than a simple straight line (linear). This is because the load and deformation are not proportional. This is called material nonlinearity. This material nonlinear problem can also be solved by the finite-element method explained in Part 1. I will discuss this in more detail in the next structural analysis.

Plastics have large material nonlinearity, so calculations must be based on accurate SS curves. Also, since the amount of deformation is large, it is necessary to consider the change in the contact state in the calculation. In particular, material properties change greatly depending on temperature, so material data (SS curve) suitable for the environment is required.

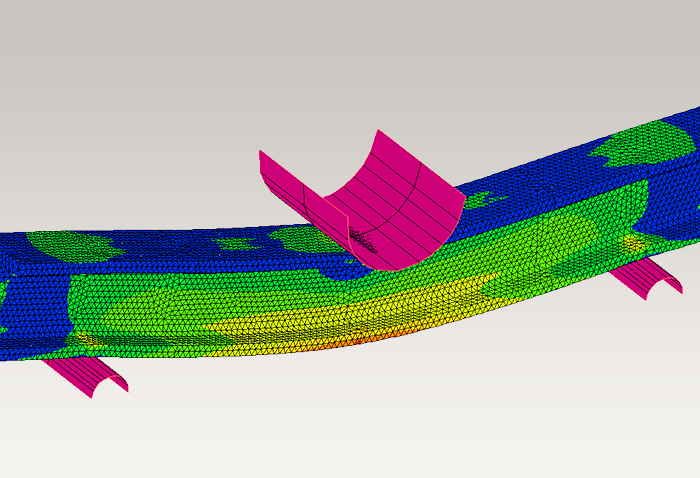

The characteristics of plastics vary greatly depending on the type and grade. Reinforced grades of plastics are highly anisotropic due to the effect of reinforcing fibers, so fiber orientation must be considered in calculations. Since the resin has a high viscosity, the fiber orientation is governed by the flow, but since it is affected by the shape of the molded product and the gate position, it is necessary to obtain the fiber orientation from the molding process analysis such as injection molding analysis and stress warp analysis. I have. This will be explained in a separate chapter.

■ Characteristics to consider depending on the type of analysis

The creep analysis takes viscoelasticity into account. This is because creep analysis requires a constitutive equation that considers viscoelasticity (time term) in order to calculate the increase in strain over time.

Also, the strain rate dependence must be taken into account in the impact analysis. Since strength and stiffness of plastics change greatly with strain rate, data on these strain rate dependencies is required.

We will discuss these topics in more detail in future publications.

Summary

Plastic is a very convenient and familiar material, but it is necessary to understand its basic characteristics in order to design it correctly. The first step is to theoretically know the properties of the plastics that we usually come into contact with one by one.

Next Part: "Introduction to analysis software"

◆You can receive the latest release information by email. Register here.

For more information about CAE, please contact us.

CAE Download Slides