product

Excellent flame retardancy, electrical properties, dimensional stability, and water resistance. It is used in photovoltaics, batteries, and communication components.

For inquiries regarding SDS and various chemical substance investigations, please make your request through your purchasing route, such as via a trading company.

We appreciate your understanding and cooperation.

An Advanced Driver-Assistance Systems (ADAS) is a driving-support technology designed to make automobile journeys safer and more comfortable for drivers.

Millimeter-wave radar, which is one of the components of ADAS, detects the distance and direction to an object by emitting short-wavelength radio waves, such as 24GHz and 76GHz, towards the object and detecting the radio waves that are reflected back.

On this page, we will introduce various Materials for millimeter wave radars that are part of ADAS.

*Click here for details on “Materials for ADAS in-vehicle cameras and head-up displays”

Asahi Kasei helps realize high-performance millimeter wave radar for safe and comfortable transportation.

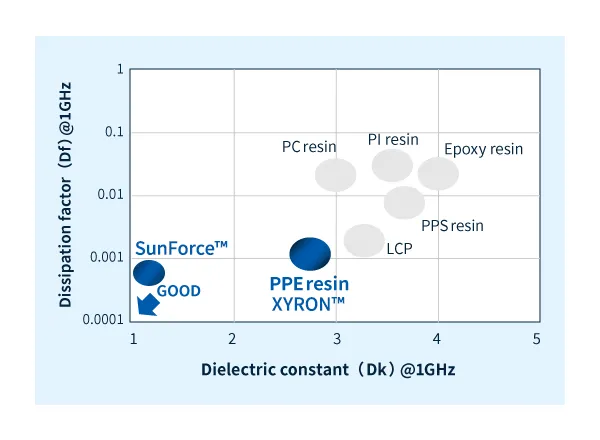

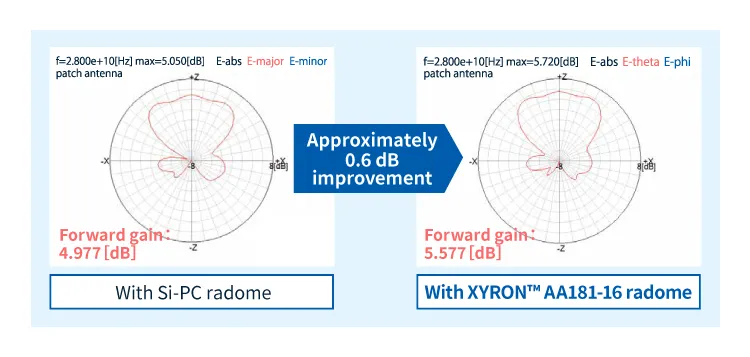

Because the radome is the outermost component of the radar system, it must be lightweight and weather-resistant; in addition, the radome should have low dielectric permittivity to achieve optimal electromagnetic-wave transmission. The need to minimize electromagnetic attenuation in the radome is particularly urgent for high-frequency systems such as millimeter-wave radars. Consequently, the relative dielectric permittivity (Dk) and loss tangent (Df)—physical properties describing the attenuation of electromagnetic waves in a material—are important characteristics of the materials used to fabricate radar components.

The parent material of Asahi Kasei’s XYRON™ products is polyphenylene ether (PPE), whose low dielectric permittivity and low loss tangent make it well-suited for use in information and communication systems.

The high glass-transition temperature of PPE also ensures that the temperature dependence of the dielectric permittivity is lower for XYRON ™products than for other heat-resistant resins.

In particular, AA181-7 is a XYRON™ development grade with excellent hydrolysis resistance and shock resistance that simultaneously offers low dielectric permittivity and compliance with the UL94V-0 flame-retardant standard, a combination that is nearly impossible to achieve using conventional materials.

To date, radomes have typically been made from polycarbonates (PCs), polybutylene terephthalate (PBT), polyphenylene sulfide (PPS), or similar materials, but these choices leave much to be desired from the standpoint of dielectric properties. In particular, the material properties of crystalline resins such as PBT and PPS vary significantly at temperatures beyond their glass transition temperature (Tg); in particular, the dielectric permittivity of such materials in high-temperature environments must be carefully monitored.

These problems may be eliminated once and for all by choosing Asahi Kasei’s XYRON™ AA181-7 development grade as a material for radomes.

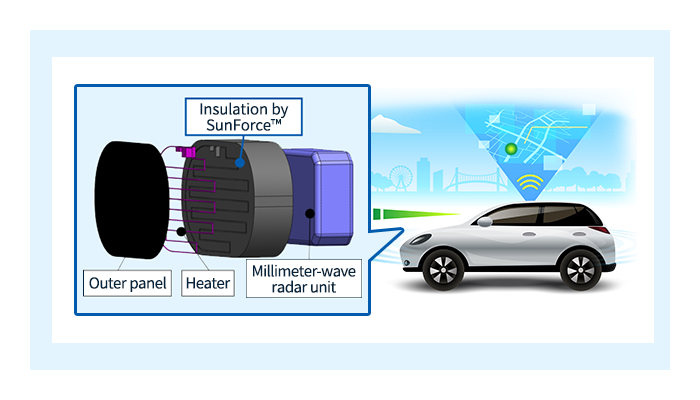

During snowfall, the accumulation of snow on the radome can increase the reflection of millimeter waves, leading to decreased detection performance. To address this issue, technology that places heaters in the radome to melt the snow has been put into practical use.

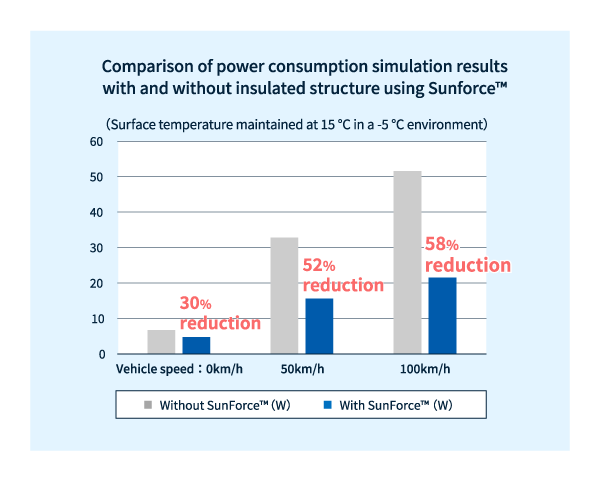

To solve this problem, Asahi Kasei proposes a structure that positionsTo solve this problem, Asahi Kasei proposes a structure that positions "SunForce™", a material made by foaming modified PPE resin, on the back of the millimeter-wave radar radome. Because of SunForce™'s high insulation properties and low dielectric characteristics, it enables the effective use of heat generated by the heater while minimizing the attenuation of electromagnetic waves in the millimeter-wave band.

As shown in the diagram below, when using SunForce™ with a thickness of 3mm and a foaming ratio of 10x, it is possible to reduce the heater power consumption required to heat the millimeter-wave radar radome.

Please feel free to contact us with any questions about our products or technologies or to request samples.

We will introduce Asahi Kasei 's engineering plastic products and technologies in more detail.

We regularly deliver product and industry information to help you gather information.