Technologies and Products

For inquiries regarding SDS and various chemical substance investigations, please make your request through your purchasing route, such as via a trading company.

We appreciate your understanding and cooperation.

2025.07.31

Technologies and Products

With the increasing number of radar applications in various industries, the pressure to reduce material and production costs as well as weight is rising. Gap waveguide slot array antennas for automotive millimeter-wave radars and cavity-type RF filters for mobile base stations are usually made of metal. The milling process applied for the surface treatment of the metal plates is cost- and time-intensive, and the switch to resin materials has been challenging due to the low platability of most resins.

Together with its partner Tsukada Riken Industries, Asahi Kasei made a significant step towards the application of its modified polyphenylene ether (m-PPE) “XYRON™” in waveguide array antennas, omitting the milling process and allowing for mass production of parts via injection moulding.

Some resins are difficult to plate using conventional wet plating processes.

Asahi Kasei has achieved wet plating on modified PPE resin “XYRON™” using Tsukada Riken Industries’ plating technology. The adhesion is sufficient for practical use and remains intact even after thermal shock testing.

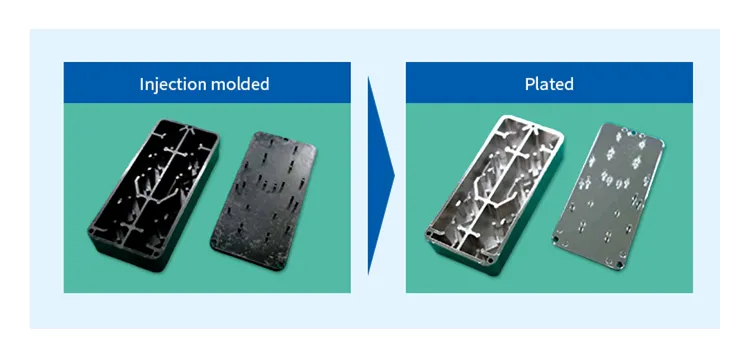

Before and After Plating Comparison on RF Filter prototypes

Before and After Plating Comparison on RF Filter prototypes

Compared to the cost of producing parts by metal milling, performing wet plating after injection molding can significantly reduce expenses. Conventional resins that cannot be plated with standard wet processes require expensive pretreatment.This cost-saving effect makes “XYRON™” a candidate for applications such as gap waveguide slot array antennas for automotive millimeter-wave radar and cavity-type RF filters for mobile base stations.

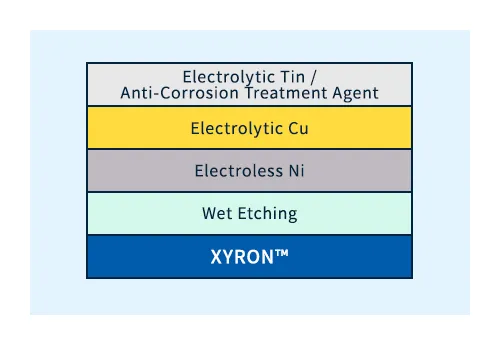

Example 1: Cost-Optimized Film Structure

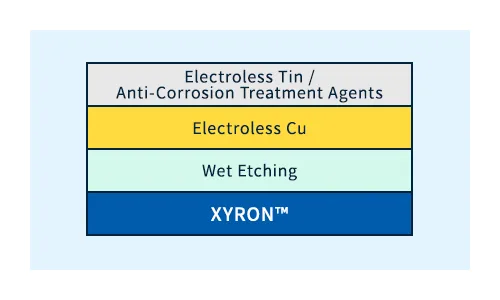

Due to XYRON’s excellent plating properties, the adhesion to the metal plating can be ensured even with direct electroless Cu plating or electrolytic Cu plating, enabling low-cost plating and contributing to cost reduction.

Example 2: Cost-Optimized Film Structure

Asahi Kasei continues to collaborate with various partner companies like Tsukada Riken Industries, accumulating diverse expertise to support customers’ manufacturing efforts.

If you would like more detailed information, please contact us using the form below.

Please feel free to contact us with any questions about our products or technologies or to request samples.

We will introduce Asahi Kasei 's engineering plastic products and technologies in more detail.

We regularly deliver product and industry information to help you gather information.