Technologies and Products

For inquiries regarding SDS and various chemical substance investigations, please make your request through your purchasing route, such as via a trading company.

We appreciate your understanding and cooperation.

2026.01.09

Technologies and Products

SunForce™ is a rigid bead foam made mainly from modified polyphenylene ether (m-PPE) resin, which is a type of engineering plastic. Thanks to its engineering plastic origin, it boasts superior mechanical properties and high strength. Leveraging these characteristics, Sunforce™ offers a lineup with low expansion ratios ranging from 3.5 to 15 times.

General-purpose foamed plastics like expanded polystyrene (EPS) and expanded polypropylene (EPP), which have high expansion ratios, are widely used for cushioning materials in home appliances and precision equipment, as well as for insulation panels, due to their lightness and thermal insulation properties. In contrast, SunForce™ ’s relatively low expansion ratio (3 to 15 times) rigid bead foam is used in applications that require not only lightness but also greater rigidity, dimensional accuracy, and repeated durability, such as automotive materials where energy absorption is needed.

Compared to expanded polypropylene (EPP), SunForce™ has more than twice the compressive strength at the same magnification. When designing a material with the same compressive strength, a lower density is required, making it possible to reduce the weight of the same shape.

Comparison of Compressive Strength between Rigid Foam Sunforce™ and Expanded Polypropylene (EPP)

Comparison of Compressive Strength between Rigid Foam Sunforce™ and Expanded Polypropylene (EPP)

SunForce™ excels not only in compressive strength but also in bending strength and modulus of elasticity, contributing to thinner and smaller designs compared to conventional shapes. Additionally, its small bead size makes it well-suited for creating intricate shapes.

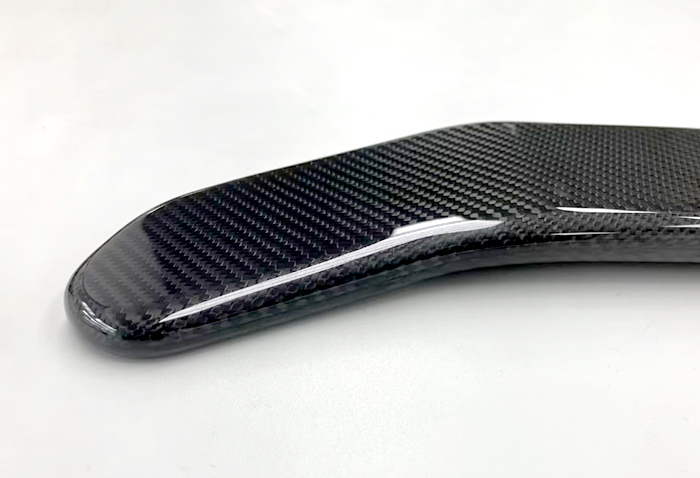

Molding Examples of Rigid Foam SunForce™

Molding Examples of Rigid Foam SunForce™

SunForce™ is made from engineering plastic materials with high heat resistance, making it highly durable under heat.

SunForce™ Heat Resistance

SunForce™ Heat Resistance

Leveraging its strength, SunForce™ is used in fixed-wing drone bodies. Fixed-wing drones are used for tasks such as surveying and infrastructure inspection, flying at high speeds in the sky.

In the air, the drone body is subjected to significant drag due to air resistance, so the material must be lightweight and strong, and also able to withstand temperature increases from direct sunlight. SunForce™ is resistant to extreme heat and rain, making it an optimal material for drone bodies.

Application Example: Fixed-Wing Drone Body

Application Example: Fixed-Wing Drone Body

Other examples of SunForce™ ’s consideration and adoption are available. Please feel free to contact us for more information.

Please contact us to ask any questions, discuss any concerns, and request samples.

Please feel free to contact us with any questions about our products or technologies or to request samples.

We will introduce Asahi Kasei 's engineering plastic products and technologies in more detail.

We regularly deliver product and industry information to help you gather information.