Exhibition Info

For inquiries regarding SDS and various chemical substance investigations, please make your request through your purchasing route, such as via a trading company.

We appreciate your understanding and cooperation.

2026.02.09

Technologies and Products

The EV market—particularly for electric two‑wheelers—continues to grow rapidly in Asia and India. As driving range and performance continue to improve, batteries must deliver higher energy density, while meeting increasingly stringent safety requirements.

Thermal runaway, in which abnormal heat generation in one cell propagates sequentially to surrounding cells, is one of the most serious risks in EV batteries. In India’s EV battery safety standard, AIS‑156, the suppression of thermal runaway is designated as a key evaluation criterion.

The modified PPE resin “XYRON™” provides excellent heat resistance, electrical insulation, and flame‑propagation resistance, making it an ideal material for AIS‑156–compliant and next‑generation high‑energy batteries.

To evaluate XYRON™ ’s thermal‑runaway‑suppression and flame‑propagation‑prevention capabilities, we conducted a full‑scale thermal runaway test using 4680 NMC cylindrical cells in collaboration with UL Solutions.

<Test Condition>

<Test Results>

These results confirm that XYRON™ can effectively suppress thermal runaway even in 4680 NMC cells.

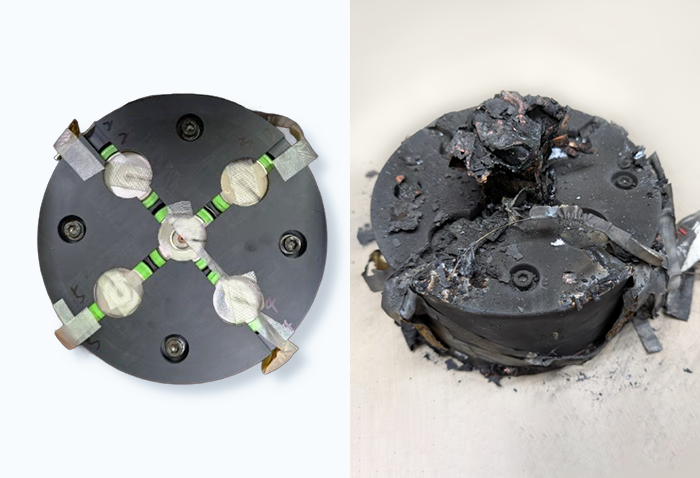

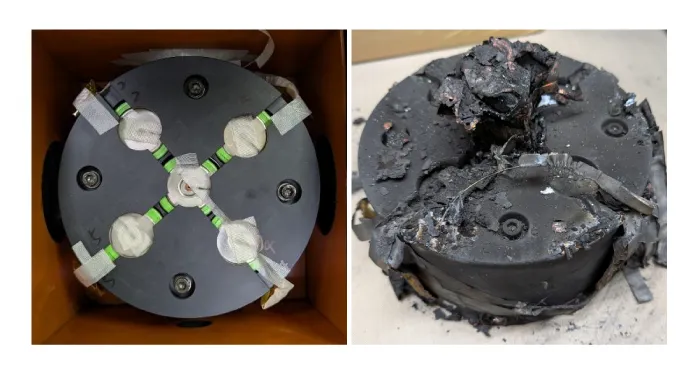

Left: Before the test—ylindrical battery cells were placed in cell holders made of XYRON™ 540Z (unreinforced) (2.0 mm spacing)

Left: Before the test—ylindrical battery cells were placed in cell holders made of XYRON™ 540Z (unreinforced) (2.0 mm spacing)

Right: After the test—no thermal runaway occurred in the four adjacent cells surrounding the triggered center cell.

Traditionally, potting materials and gap fillers have been used to ensure thermal management, thermal runaway mitigation, and structural stability. However, these materials increase weight, extend manufacturing time, and reduce recyclability. Because XYRON™ inherently offers excellent heat resistance, insulation, and flame‑propagation resistance, adopting a high‑cell‑wall structure enables both enhanced safety and weight reduction while reducing the need for potting materials.

Key Benefits of High‑Cell‑Wall Design

✔ Cost reduction through decreased use of potting materials / gap fillers

✔Lightweighting enabled by potting‑less and thin‑wall molding

✔ Excellent electrical insulation and heat resistance

✔ Improved maintainability and recyclability due to potting‑less design

✔ Higher energy density made possible by the above advantages

This structural approach enables compliance with safety standards without adding unnecessary material weight.

Please feel free to contact us to learn how XYRON™ can contribute to AIS‑156–compliant thermal runaway countermeasures and improved safety in next‑generation battery designs.

If you would like more detailed information, please contact us using the form below.

Please feel free to contact us with any questions about our products or technologies or to request samples.

We will introduce Asahi Kasei 's engineering plastic products and technologies in more detail.

We regularly deliver product and industry information to help you gather information.