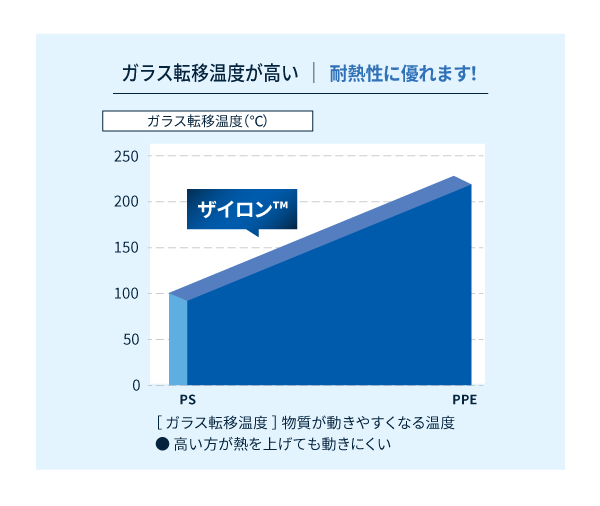

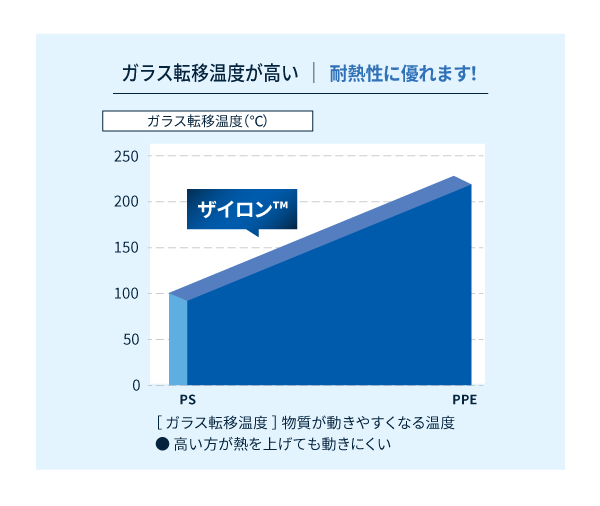

耐熱性

PPEはガラス転移温度約220℃を有する、耐熱性の高い樹脂です。変性PPE樹脂ザイロン™においては、ガラス転移温度90~220℃まで幅広い材料ラインナップを有しています。また、耐熱水性・耐加水分解性にも優れます。

ザイロン™は、旭化成の変性PPE(m-PPE、変性ポリフェニレンエーテル)樹脂です。

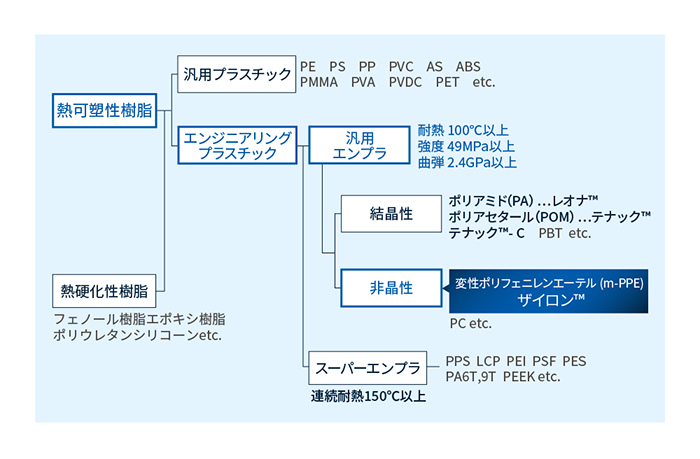

変性PPE樹脂は、PPE(ポリフェニレンエーテル) 樹脂と他樹脂を混合したポリマーアロイの総称です。PPEは、耐熱性・難燃性・絶縁性・寸法安定性・低吸水性に優れた、比重が小さいエンジニアリングプラスチック(エンプラ)で、非晶性の熱可塑性樹脂です。

旭化成は、原料 (2,6-キシレノール) からPPEを生産し、他樹脂とアロイ・コンパウンドした豊富なグレードラインナップを展開しています。アロイ毎に各種グレードをご用意し、変性PPE樹脂のアジアNo.1メーカー*としてお客様のニーズにお応えします。

*出典:富士経済「2025年エンプラ市場の展望とグローバル戦略」の販売量より。

PPEは、耐熱性、機械的強度に優れる 「エンジニアリングプラスチック (エンプラ)」 に分類されます。

PPEは、エンプラの中でも「非晶性」の「熱可塑性樹脂」であり、変性PPE樹脂 ザイロン™は、下記の性質を併せ持つエンプラ材料です。

PPEはガラス転移温度約220℃を有する、耐熱性の高い樹脂です。変性PPE樹脂ザイロン™においては、ガラス転移温度90~220℃まで幅広い材料ラインナップを有しています。また、耐熱水性・耐加水分解性にも優れます。

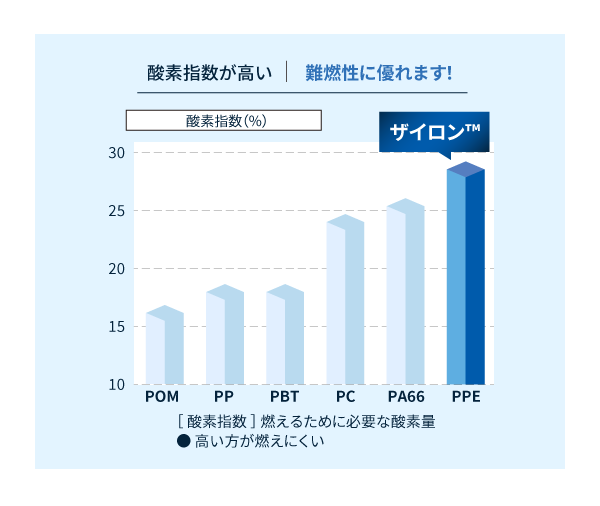

PPEは酸素指数 (燃えるために必要な酸素量)が高く、難燃化しやすい樹脂です。変性PPE樹脂 ザイロン™では、優れた難燃性を有するグレードを多数ラインナップしています。

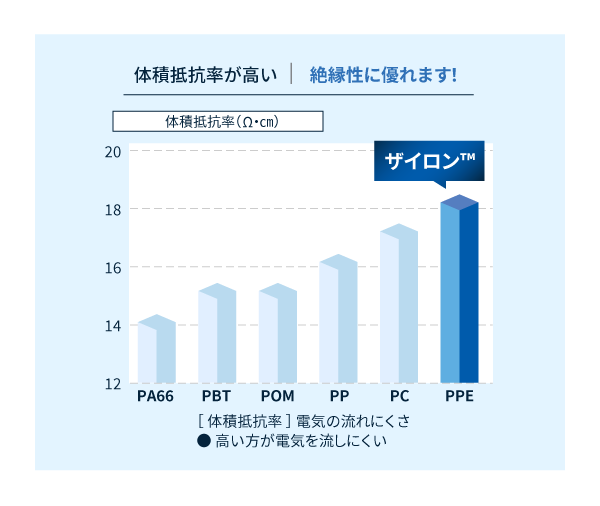

PPEは、体積抵抗率(電気の流れにくさ)が高く、絶縁性に優れる樹脂です。変性PPE樹脂 ザイロン™では、耐トラッキング性等の電気特性に優れたグレードをラインナップしています。

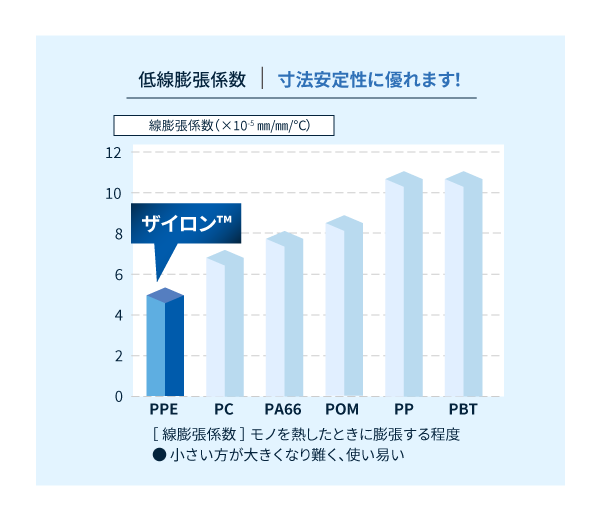

PPEは、線膨張係数がエンジニアリングプラスチック中で最も小さく、成形収縮率も小さい樹脂です。変性PPE樹脂 ザイロン™では、寸法安定性、寸法精度に優れたグレードをラインナップしています。

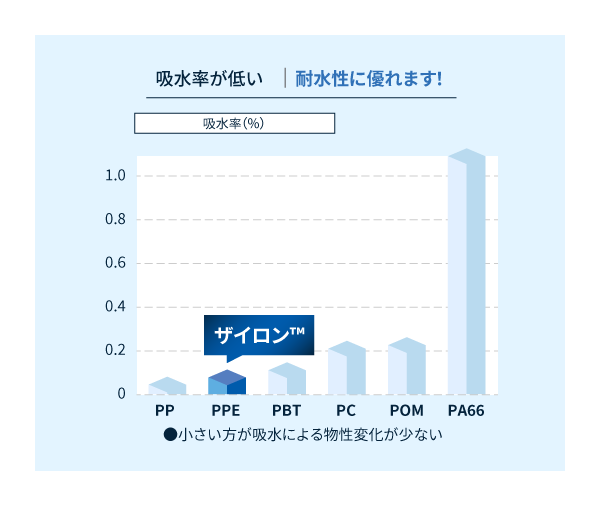

PPEは、吸水率が低い樹脂です。そのため、変性PPE樹脂 ザイロン™の各グレードでは吸水による物性変化・寸法変化が小さい特徴があります。

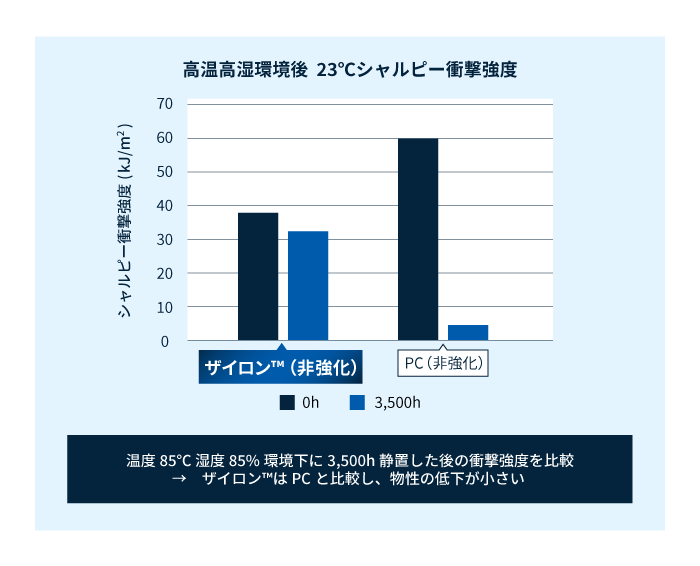

また、優れた耐熱性も有するため、耐熱水性、耐加水分解性にも優れています。以下表では、高温高湿環境下3,500時間静置後のシャルピー衝撃強度において、ザイロン™の物性低下が小さいことを示しています。

さらに、酸やアルカリに対しての耐性も強く、環境への耐久力に優れています。

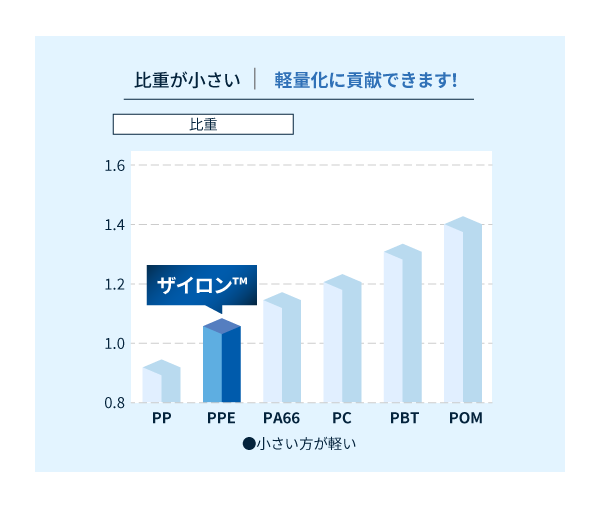

PPEは、エンジニアリングプラスチックの中で最も比重が小さく、軽量な素材です。

変性PPE樹脂 ザイロン™を使用することにより、部品軽量化に貢献できます。

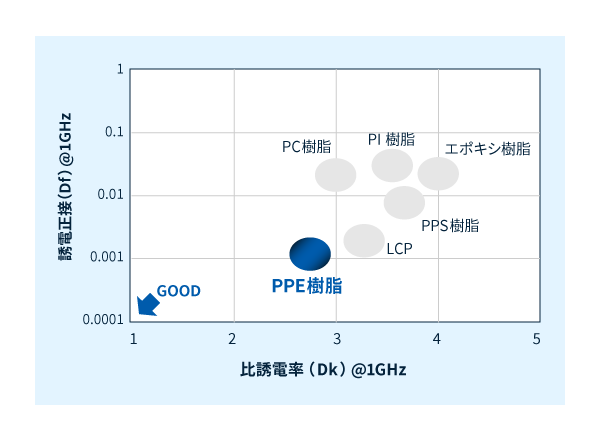

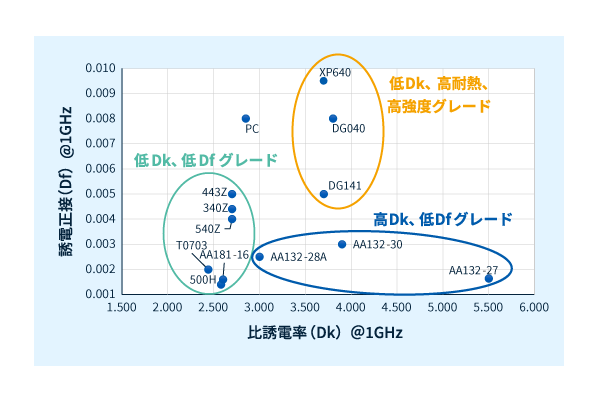

PPEは、低誘電率、低誘電正接な樹脂であり、伝送損失を小さく抑えられるため、情報通信分野の活用に適しています。また、PPEは高いガラス転移温度を有していることから、他の高耐熱性樹脂に比べて誘電特性の温度依存性が小さい点も特徴です。

変性PPE樹脂 ザイロン™では、PPE由来の低誘電特性と旭化成コンパウンド技術を組み合わせることで、幅広い誘電特性ニーズに適応可能です。これにより、高誘電率・低誘電正接グレードなど様々な誘電特性を持った、Dk/Dfコントロールグレードを備えています。

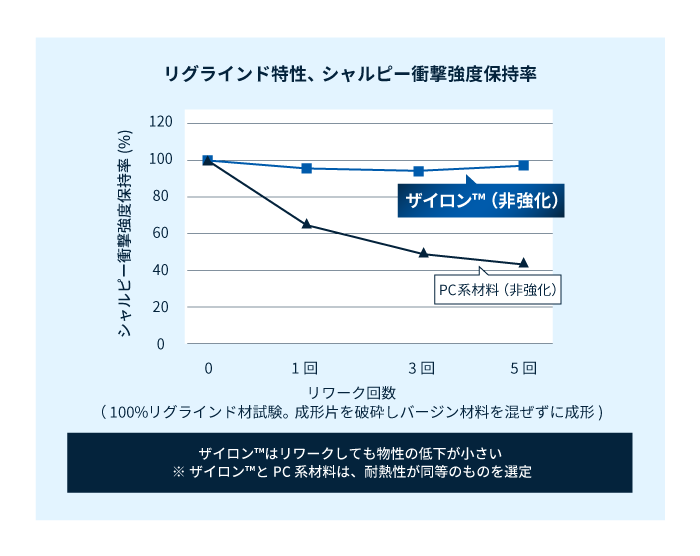

優れた耐熱性、耐加水分解性等の特徴から、変性PPE樹脂 ザイロン™はリグラインド時の物性低下が少ない材料です。以下表では、加速試験として100%リワーク材を使った衝撃強度を測定し、ザイロン™はリワークしても物性の低下が小さいことを示しています。

また、エンジニアリングプラスチックの中で最も比重が小さく、軽量な素材であることから、製品を作る際に素材使用量が少なく、再生利用と合わせてザイロン™を使用することにより、製品サイクルトータルとしての素材使用量を減らすことができ、環境負荷低減に貢献することができます。

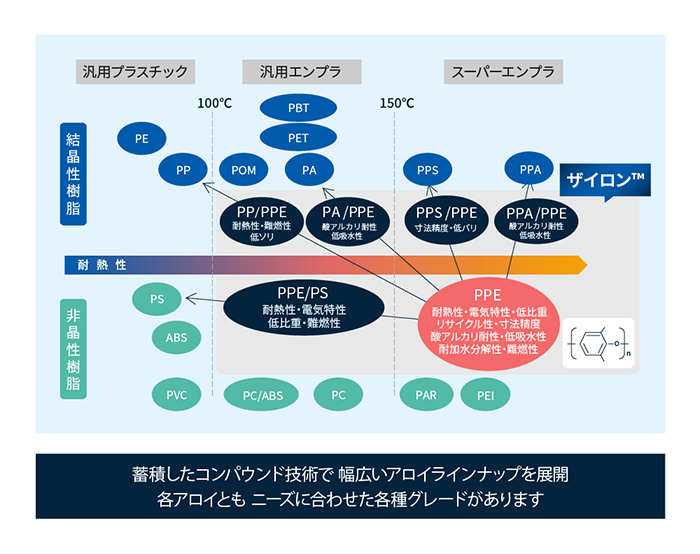

変性PPE樹脂 ザイロン™は、PPEを、他樹脂とコンパウンドしたものです。

旭化成は、原料 (2,6-キシレノール) からPPEを生産し、各種樹脂 (ポリスチレン:PS、ナイロン:PA、ポリプロピレン:PP、ポリフェニレンサルファイド:PPS、ポリフタルアミド:PPA等) とコンパウンドしたポリマーアロイをラインナップしています。各アロイ毎に各種グレードをご用意し、変性PPE樹脂のアジアNo.1メーカー*として幅広いニーズにお応えします。

*出典:富士経済「2025年エンプラ市場の展望とグローバル戦略」の販売量より。

また、変性PPE樹脂 ザイロン™には、主材であるPPEを他樹脂とコンパウンドしていない 「PPE原料 (PPE粉末)」 もございます。

PPE原料は、高耐熱・低比重で、電気特性・難燃性に優れ、ポリスチレンとの優れた相溶性を備える非晶性ポリマーです。

世界各国に拠点を設けており、グローバルにお客様をサポートいたします。

さらに、設計シミュレーション技術である「樹脂CAE技術」により、お客様の製品設計・開発をサポートいたします。

ザイロン™PPE/PSグレードは、難燃性および耐熱性において、幅広いグレードをラインナップしています。フィラーを最適化することによって、ご要望に応じ、各種の機械的性質(剛性、靭性、低反り性、寸法精度等)を有するグレードや、導電性を有するグレード、制振・静音性に優れた「Vシリーズ」、飲料水接触用途向け「Wシリーズ」などを提供しています。

ザイロン™アロイグレードは、汎用からスーパーエンプラまでの結晶性樹脂とPPEをアロイ化させて、 PPEの特徴にさらに耐熱性や耐薬品性など、各結晶性樹脂の特徴を付与したものです。低反り・耐薬品性に優れたPP/PPE、耐熱・低吸水・耐油性を有するPA/PPE、高耐熱・低バリ・低反りのPPS/PPE、高耐熱・低吸水を達成するPPA/PPEのラインナップがございます。

下表中のグレード名をクリックして頂くと、各グレードの詳細データがご覧いただけます。さらに、ボタンをクリックして頂くと、各シリーズの特徴がご覧いただけます。

他樹脂とコンパウンド(混錬)加工する前のPPE樹脂単体(粉体)の取り扱いもございますので、お気軽にお問い合わせください。

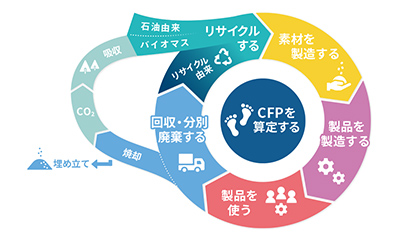

また、カーボンニュートラル実現に向け、ザイロン™では、バイオマス原料由来のPPEの開発や、再生プラスチック(PCR)率15-40%のリサイクルグレードの開発に取り組んでいます。

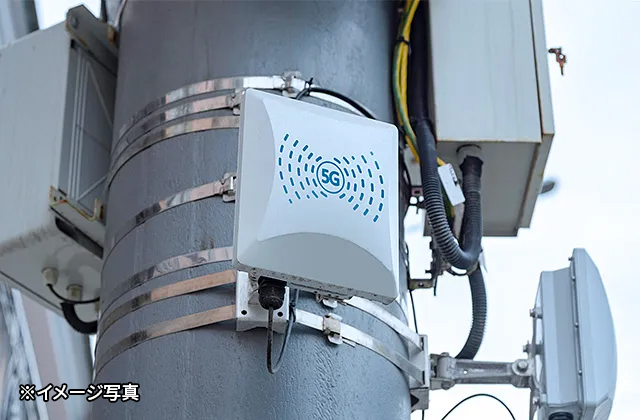

通信系各種アンテナのカバー(レドーム)、MIDアンテナの基材。

優れた誘電特性が求められる。

:

:

443Z, 他開発グレード

特定の周波数帯の信号を通過させ、その他の周波数信号を遮断するデバイス。

元々金属で製造されており、樹脂化に際し低線膨張係数・耐熱性・メッキ性が求められる。

誘電体の波長短縮効果を利用し、位相をシフトさせるためのデバイス。

使用に合わせた誘電率と誘電正接のバランスが求められる

太陽光パネル裏に設置される基盤及び電気配線などを保護するためのボックス。

屋外に設置されるため、難燃性・電気特性だけでなく、耐候性・耐加水分解性等も求められる。

ザイロン™に関するご質問・ご相談・サンプル

のご依頼をお待ちしております。