Product

A bead made by foaming modified PPE resin and have excellent flame resistance, low dielectric properties, dimensional accuracy.

For inquiries regarding SDS and various chemical substance investigations, please make your request through your purchasing route, such as via a trading company.

We appreciate your understanding and cooperation.

Modern home appliances such as washer-dryers and air conditioners (HVAC) are becoming increasingly sophisticated to enhance convenience and comfort. However, as functionality improves, power consumption also tends to rise, creating a need for effective energy-saving measures to reduce both environmental impact and electricity costs. Technologies such as inverter control, heat pumps, and high-efficiency motors have been introduced to improve energy efficiency. The materials used in these applications must also withstand harsh conditions, including high temperatures and humidity.

In recent years, the environmental impact of refrigerants used in air conditioning systems (HVAC) has become a major concern. Traditional fluorocarbon-based refrigerants, widely used in the past, have high global warming potential (GWP) and pose a significant environmental burden. As a result, a global shift toward low-GWP refrigerants is underway. However, many of these alternatives come with a new challenge—their increased flammability.

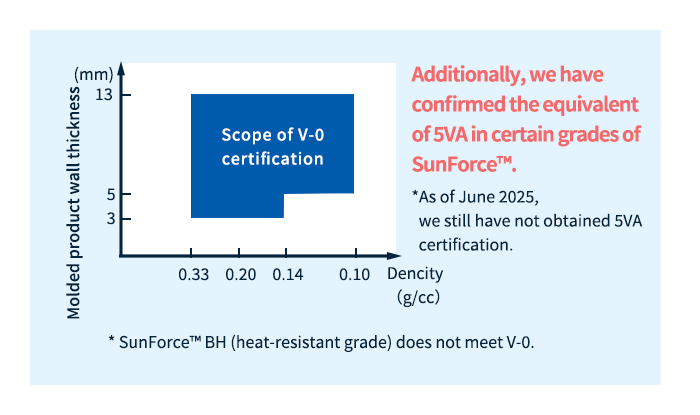

Asahi Kasei 's SunForce™ engineering plastics foam insulation material is highly flame resistance (UL94 V-0) and enables efficient energy use while ensuring safety when used in insulation for HVAC systems that use alternative chlorofluorocarbons. It also demonstrates excellent insulation performance even in high-temperature, high-humidity environments, contributing to reduced power consumption during operation.

SunForce™ is a particle foam made from modified PPE resin, XYRON™. It combines the unique properties of modified PPE—such as heat resistance, dimensional stability, low water absorption, and hydrolysis resistance—with the advantages of bead foam, including light weight and excellent moldability (design flexibility). Thanks to its outstanding flame retardancy and heat resistance, SunForce™ achieves UL94 V-0 certification, offering a rare balance of safety and performance in a foam material.

SunForce™ also offers excellent productivity through in-mold foaming, making it ideal for mass production. In addition, its closed-cell structure provides outstanding thermal insulation performance.

To reduce environmental impact, a global shift toward low-GWP refrigerants is underway in air conditioning (HVAC), refrigeration, and freezing equipment. *¹ However, many of these refrigerants are highly flammable, posing new safety challenges.

In response to this, the international standard UL 60335-2-40 for electrical appliances was revised in 2022 to include enhanced safety requirements related to refrigerant flammability in heat pump systems.*²

Similarly, UL 60335-2-24, the standard for refrigeration and freezing appliances, requires the use of insulation materials that meet the UL94 5VA flame-retardant rating.*³

*1 Reference:REGULATION (EU) 2024/573 OF THE EUROPEAN PARLIAMENT AND OF THE COUNCIL of 7 February 2024

*2 Reference:Updated Requirements for Refrigerant Detection Systems (UL Solutions)

*3 Reference:Explore the New Edition of UL 60335-2-24 (UL Solutions)

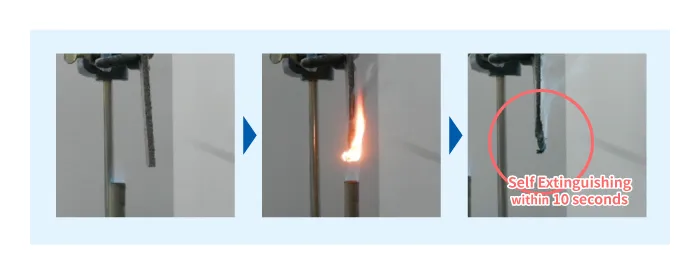

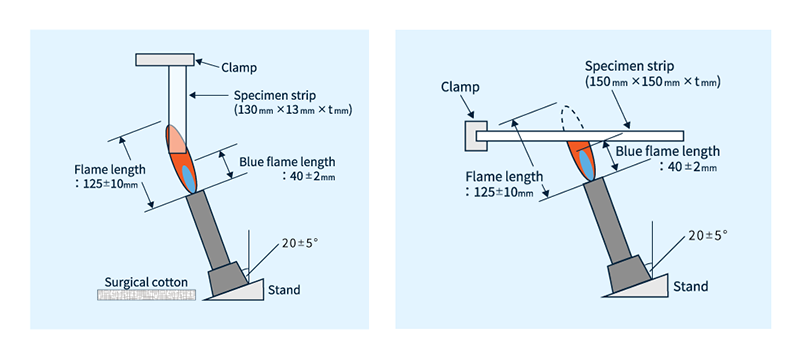

SunForce™ features excellent flame retardancy with UL94 V-0 certification (self-extinguishing performance), and complies with the polymer material requirements around electrical connection points as defined in UL 60335-2-40 for heat pumps, air conditioners, and dehumidifiers.

In addition, SunForce™ has been confirmed to exhibit performance equivalent to UL94 5VA certification. This suggests its strong potential to meet the flame-retardant requirements for insulation materials as specified in UL 60335-2-24 for refrigeration and freezing equipment.

By using SunForce™ as an insulating material for air conditioning (HVAC) equipment and refrigeration/freezing equipment not only saves energy and prevents condensation through insulation, but also contributes to safe designs when using flammable refrigerants.

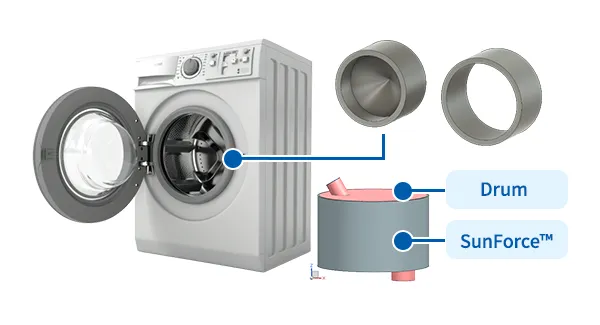

SunForce™ maintains stable mechanical strength and dimensional stability even under high-temperature, high-humidity conditions found in washer-dryers, making it ideal for the mass production of high-performance insulation materials. Its excellent flame retardancy (UL94 V-0) also makes it suitable for placement around electrical connection points in home appliances and electronic devices.

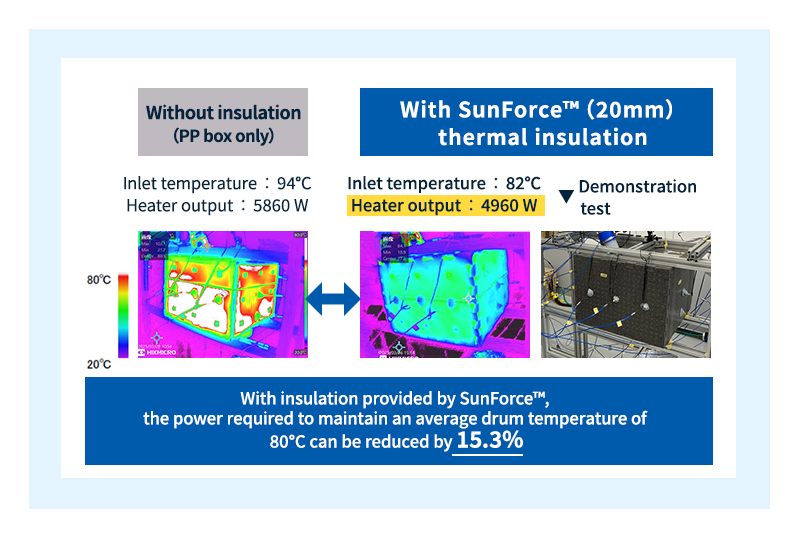

In a demonstration test using a drum-type washer-dryer, as shown below, SunForce™'s superior thermal insulation enabled a 15.3% reduction in the power required to maintain internal drum temperature during the drying cycle—contributing significantly to energy efficiency.

By leveraging this energy-saving performance, SunForce™ thermal insulation can be applied to commercial equipment such as coin-operated laundry machines, where it is expected to improve energy efficiency during the drying process. This may lead to benefits such as reduced utility costs for both owners and end users.

Our download materials provide further details on the above demonstration test, as well as simulation data from CAE analysis under dryer-like conditions, highlighting the energy-saving potential of SunForce™.

For further details or sample requests, please contact us via the form on our website.

Please feel free to contact us with any questions about our products or technologies or to request samples.

We will introduce Asahi Kasei 's engineering plastic products and technologies in more detail.

We regularly deliver product and industry information to help you gather information.