product

Excellent flame retardancy, electrical properties, dimensional stability, and water resistance. It is used in photovoltaics, batteries, and communication components.

For inquiries regarding SDS and various chemical substance investigations, please make your request through your purchasing route, such as via a trading company.

We appreciate your understanding and cooperation.

Solar power generation exploits the photovoltaic effect, in which sunlight energy is converted directly into electrical energy by semiconductor devices known as photovoltaic cells. This method, which harvests power from the fully renewable resource of solar energy, promises to slash energy costs and accelerate progress toward the United Nation’s Sustainable Development Goals—and, for these reasons, has grown explosively in recent years.

According to the International Energy Agency (IEA), the total power produced by photovoltaic installations grew at an average annual rate of 24% between 2010 and 2020. Within IEA forecasts predicting trends in global power-generation capacity under various future scenarios, solar energy consistently ranks among the most promising of the various available power sources, and the market for photovoltaics is widely expected to continue growing rapidly in the years to come.

For over 15 years, Asahi Kasei has been developing, selling, and providing customer support for our family of engineering plastics optimized for connectors and junction boxes in photovoltaic installations. These products, designed for long service lifetimes in harsh outdoor environments, have been certified to meet a broad range of specifications–including for flame retardance (e.g., UL94 V-0, 5VA), tracking resistance (CTI), weather resistance (UL746C f1), long term property evaluation (UL746B RTI), and heat resistance (e.g., ball-pressure temperature)—and will help to solve your most challenging design problems.

Asahi Kasei’s XYRON™ materials are polymer alloys combining polyphenylene ether (PPE) with other resins. The XYRON™ family, which Asahi Kasei has been producing since 1979, boasts an extensive track record—occupying a key role in the history of engineering plastics—and today encompasses a full-fledged line-up of polymer alloys.

XYRON™ materials offer multiple excellent physical properties. In addition to their outstanding heat resistance, they boast flame retardance, electrical insulation property, good dimensional stability, and hydrolysis resistance, as well as low specific gravity. These polymer alloys combine the advantages of PPE with the specialized properties of various other plastics to yield unique functional properties.

XYRON™ modified PPE resins offer excellent weather resistance and are suitable for use in the harsh environments in which solar-power generators operate.

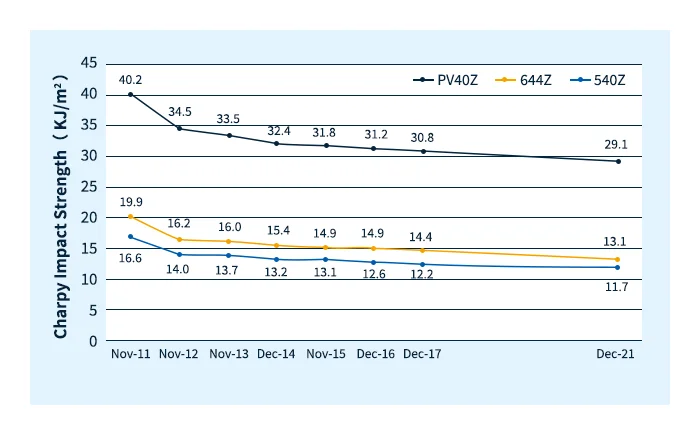

To demonstrate this, Asahi Kasei conducted exposure tests designed to mimic the operating environment faced by components of solar-power generators. In these tests, samples of various functional materials were installed at an outdoor test site in Okinawa, Japan, and held there for a period of 10 years beginning in 2011. Post-exposure tests confirmed that XYRON™ resins exhibited no catastrophic decrease in strength.

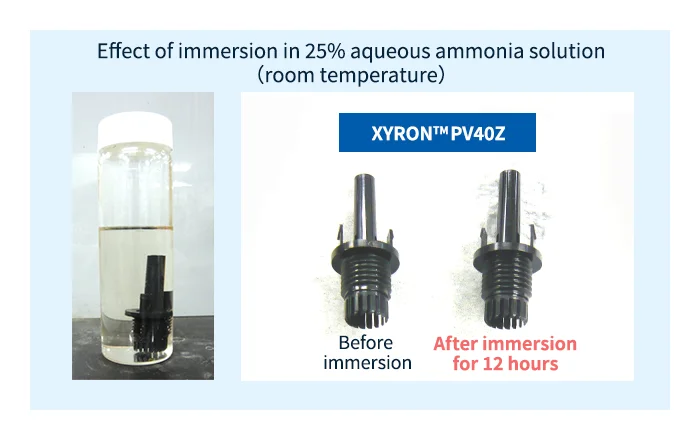

XYRON™ modified PPE resins also feature excellent ammonia resistance property. The importance of this property stems from the fact that solar panels are often installed on land previously used as farmland or pasture, and must therefore be capable of operating in contact with ammonia originating from livestock. Tests conducted by Asahi Kasei confirmed that XYRON™ materials exhibit essentially no degradation after immersion in an aqueous solution of ammonia, and these materials can thus be used for solar-power generators installed on farmland and other places.

For junction boxes in solar-power generators, Asahi Kasei recommends the 540Z, 644Z, and PV41Z grades of our XYRON™ modified PPE resins. These materials offer high tracking resistance, high hydrolysis resistance, high acid and alkali resistance, good mechanical properties in high-temperature, high-humidity environments, and good dimensional stability.

For connectors in solar-power generators, Asahi Kasei recommends the PV40Z grade of our XYRON™ modified PPE resins. This material offers a good balance of tracking resistance and cold-impact resistance and is well-suited to the design of miniature high-voltage connectors.

In addition, this material offers high hydrolysis resistance, high ammonia resistance, and no dramatic degradation in physical properties even when used in high-temperature, high-humidity environments. The outstanding electrical properties and tracking resistance of XYRON™ resin have also earned this material a role in high-voltage solar-power generation systems. The use of plastics with outstanding tracking resistance for high-voltage systems allows miniaturization of products and helps to reduce resource usage. The low specific gravity of these materials also reduces CO2 emissions during shipping.

For these reasons, Asahi Kasei has solicited advice from third-party institutions regarding viewpoints and computation methods to assess environmental impact from the standpoint of life-cycle analysis (LCA), and has received internal certification as environmental contribution products.

XYRON™ modified PPE resins have also been used for inverters and other similar components in product development.

LEONA™ is a family of polyamide resin materials (PA66, nylon resins) manufactured and sold by Asahi Kasei. A unique feature of LEONA™ materials is that the entirety of their manufacturing process—from raw materials to finished products and every stage in between—takes place in Asia.

When used in combination with XYRON™ products, the excellent heat resistance and high screw-torque property of LEONA™ resins allows the design of components offering higher stability than is possible with typical materials.

For moisture- and dust-resistant nuts at junctions between cables and connectors, Asahi Kasei recommends two grades of our LEONA™ polyamide resins: the FR370 grade, a non-halogen flame-retardant (V0) material that is highly formable, and the FG171 grade, a flame-retardant material reinforced with glass fibers for high strength.

The excellent heat resistance of these materials has also been exploited for use in other components, such as the base plates used as mounting platforms or base plate for diodes that serve as heat sources within junction boxes.

Please feel free to contact us with any questions about our products or technologies or to request samples.

We will introduce Asahi Kasei 's engineering plastic products and technologies in more detail.

We regularly deliver product and industry information to help you gather information.