Product

A bead made by foaming modified PPE resin and have excellent flame resistance, low dielectric properties, dimensional accuracy.

For inquiries regarding SDS and various chemical substance investigations, please make your request through your purchasing route, such as via a trading company.

We appreciate your understanding and cooperation.

Rechargeable batteries, also known as secondary batteries, are chemical cells that may be recharged and reused multiple times.

In years to come, we can expect LIBs and other rechargeable batteries to play increasingly crucial roles in technology and daily life, for one simple reason: the energy-storage capabilities of rechargeable batteries are widely regarded as essential for achieving the goal of carbon-neutrality by 2050. To this end, rechargeable batteries have begun to find applications not only as energy sources for electric vehicles, but also as stationary energy storage within infrastructure installations supporting various societal platforms.

Important infrastructure roles for rechargeable batteries will be to assist in balancing supply and demand at renewable energy plants. Achieving carbon neutrality will require expanding our use of renewable energy sources, but this goal is complicated by the unpredictable nature of renewable energy: the amount of power supplied by renewable energy facilities is heavily dependent on weather conditions, often resulting in significant mismatch between supply and demand. Rechargeable batteries are expected to play key roles in helping to balance such mismatches, not only at power-generation sites but also in transmission lines and at sites where power is consumed. Another important role for stationary rechargeable batteries will be to serve as backup power sources for data centers, cellular-communication base stations, and other essential infrastructure facilities on which modern digital societies depend.

Asahi Kasei offers a variety of resin materials custom-designed to streamline manufacturing processes for rechargeable batteries and encourage more effective use of batteries both in daily life and in infrastructure applications.

* Asahi Kasei’s materials for in-vehicle batteries are discussed on the page titled “Materials for automobile batteries.”

Asahi Kasei’s SunForce™ is a foam based on our XYRON™ modified polyphenlyene ethers. These products combine the unique advantages of foams—light weight and good thermal insulation—with flame retardance, dimensional stability, the ability to form products with thin walls, and other advantages far beyond the capabilities of conventional foams.

SunForce™ is a foam molding material that can be used in areas where flame resistance is required. It is the first particle foam beads material in the world to receive the extremely high level of flame resistance "V-0" certification under UL-94, the flame Flame retardance standard for plastics and components.

SunForce™ is lightweight foam with the unique advantage of being intrinsically fire-retardant (UL94V-0); to date they have been adopted or evaluated for applications to peripheral components surrounding battery packs in electric vehicles. SunForce™ is also well-suited for forming the trays used in the manufacture and shipping of LIBs. In particular, trays made from SunForce™ foam offers the following advantages:

Please feel free to contact us for further information on SunForce™ foam, including dimensional tolerances and chemical-resistance data.

Asahi Kasei’s LEONA™ polyamide resin is an engineering plastics featuring high strength, high rigidity, high heat resistance, and outstanding chemical resistance. These materials may be further strengthened by reinforcing them with glass fibers or similar fillers, improving their strength, rigidity, durability, and dimensional stability.

Here we present specialized LEONA™ grades suitable for secondary processing steps such as laser welding or laser marking. These are ideal materials for system components such as battery casings, and components made from these materials can be smaller in size in lighter in weight than components made from other materials.

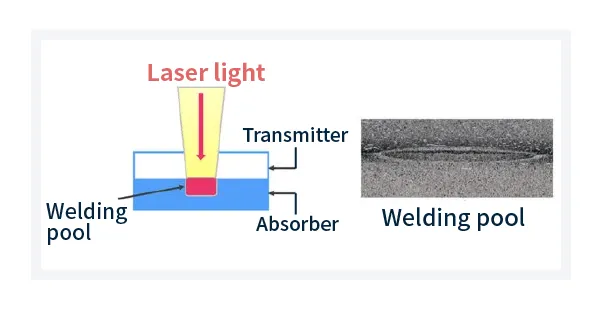

Laser welding is a secondary processing technique used to form strong junctions between components.

One scenario in which welding proves useful is the manufacture of batteries or other products containing high-energy-density components such as electronic substrates or battery packs that must be tightly enclosed inside a hermetically-sealed chassis. However, conventional welding techniques such as vibration welding or ultrasonic welding are not recommended for this purpose as they may damage the delicate system components inside the chassis. (Meanwhile, using screws or similar hardware to seal the chassis has the drawback of requiring extra space to accommodate boss regions.)

Instead, we use laser welding, which allows the formation of strong junctions with no risk of damage to internal components, thereby allowing the size and weight of manufactured products to be reduced.

Techniques for imprinting information onto products are important for ensuring product traceability and reliability.

One such technique is laser marking, in which laser irradiation of a product generates bubbles in surface resin layers, leaving behind indelible marks on the product surface.

Asahi Kasei’s LEONA™ SN11B polyamide resin is a high-strength, high-rigidity, UL94V-0 (0.75 mm)-certified flame-retardant material that is halogen- and red-phosphorus free and has a comparative tracking index (CTI) equal to or greater than 600V, PLC=0. In addition to these specifications, LEONA™ SN11B boasts excellent welding strength.

Moreover, LEONA™ SN11B is ideally suited for laser marking, producing clear, precise lettering—even for extremely small characters—and an outstanding takt time, thus helping to reduce the size and weight of final products. SN11B is ideally suited for laser marking, producing clear, precise lettering—even for extremely small characters—and an outstanding takt time, thus helping to reduce the size and weight of final products.

Please feel free to contact us with any questions about our products or technologies or to request samples.

We will introduce Asahi Kasei 's engineering plastic products and technologies in more detail.

We regularly deliver product and industry information to help you gather information.