product

Excellent self-lubricating nature, fatigue behavior, and oil resistance. It is used in gears, bearings, automotive interiors and medical parts.

For inquiries regarding SDS and various chemical substance investigations, please make your request through your purchasing route, such as via a trading company.

We appreciate your understanding and cooperation.

The use of metallic coloration to impart a sense of sophistication and luxury is ubiquitous in modern product manufacturing.

Typical methods for imparting metallic finishes to products involve painting or plating processes.

However, such approaches are costly due to the multiple processing steps they require, and have the additional drawback of polluting the environment through the use of solvents at various stages.

To address these difficulties, Asahi Kasei has developed a novel manufacturing technology in which metallic materials are blended with resins to impart a lustrous metallic sheen.

Asahi Kasei recommends our TENAC™-C ZM413 metallic-colored polyacetal copolymer to eliminate painting steps from your production process.

Polyacetal, also known as polyoxymethylene (POM), features excellent mechanical properties, sliding behavior, and chemical resistance, and is used for many structural components and internal components.

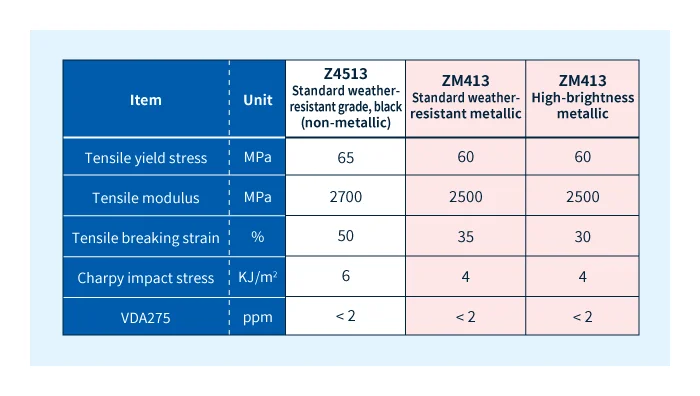

The POM resin "TENAC™ -C ZM413" is a metallic-tone POM copolymer that has the same physical properties and weather resistance as general weather-resistant grades and meets the in-car environmental standards (reduction of volatile components) of automobile OEMs.

These products are available in a wide range of color variations, and we have developed high-brightness and high-luster versions as well.

The physical properties and weather resistance of these products are equivalent to those of standard weather-resistant grades, and they also comply with various automotive OEM regulations restricting the emission of VOCs for materials intended for use in automobile interiors (VDA275<2 ppm).

Typical methods for imparting metallic finishes to products involve painting or plating the surfaces of base resins.

Such approaches are costly due to the multiple processing steps they require, and have the additional drawback of polluting the environment through the use of solvents at various stages.

TENAC™ -C ZM413, it is possible to omit the painting process and cover these shortcomingsBy using .

Please feel free to contact us with any questions about our products or technologies or to request samples.

We will introduce Asahi Kasei 's engineering plastic products and technologies in more detail.

We regularly deliver product and industry information to help you gather information.