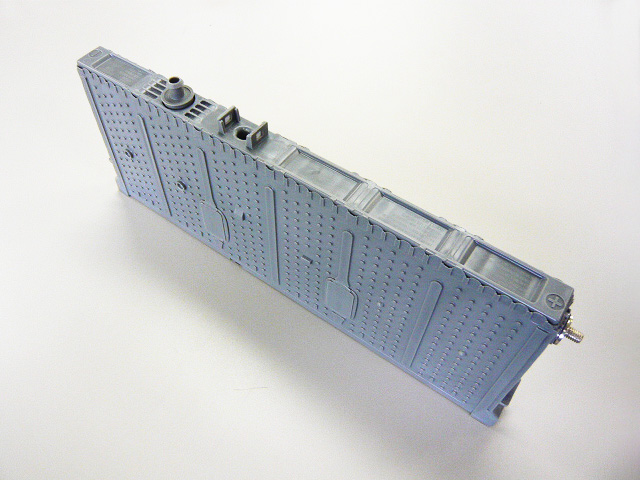

EVバッテリーケース

EVバッテリーを収める筐体。外部からの耐衝撃性、大型部品であるため寸法安定性等が求められる

48Vマイルドハイブリッド車のバッテリーケースの樹脂化。落下衝撃試験合格のために、樹脂CAEシミュレーションによる形状提案と高い機械強度を備えるレオナSGシリーズを組み合わせた事例。

製品

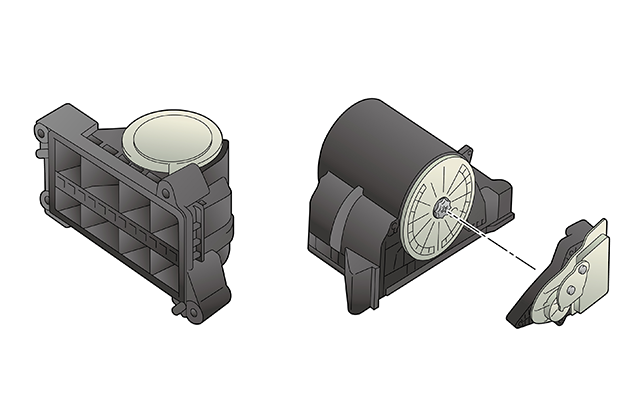

自動車の燃料蒸発ガスが大気に放出されないよう、活性炭でガスをろ過・吸着させる部品。

エンジン近傍であり耐熱性や、部品としての生産性が求められる。

※イメージ写真

※イメージ写真

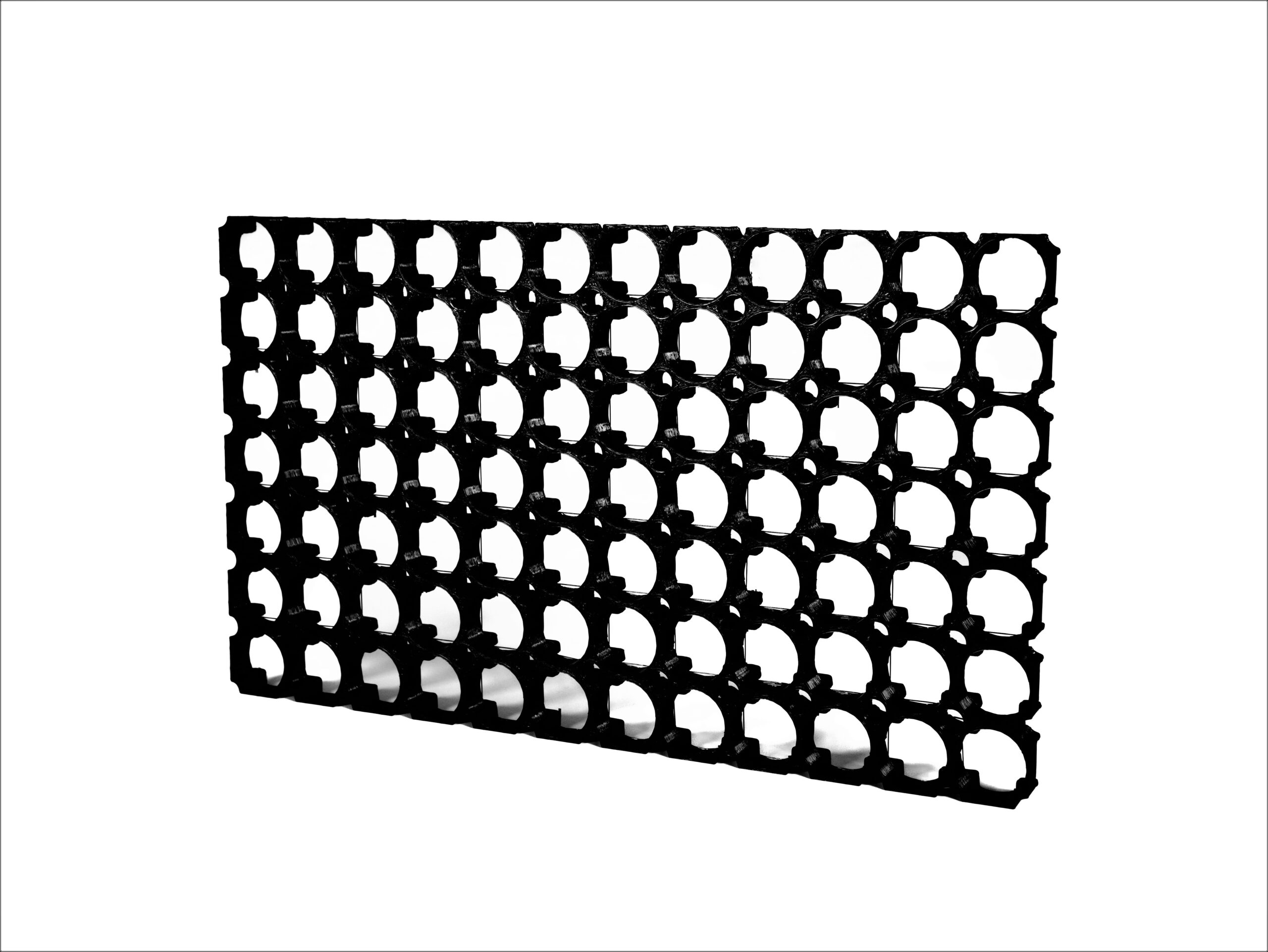

EVバッテリーの円筒型セルを収める保持部品。

軽量性・難燃性・耐熱性が求められる。

EVバッテリーのセル間を仕切る絶縁部品。

薄肉・軽量性・難燃性等が求められる。

EV 駆動モーターに装着される防振装置を取り付けるためのブラケット。

モーターを支える防振装置を取り付けるため、高い強度と耐疲労性が求められる。

水冷式バッテリーEVにおける熱マネジメントのために、各種冷媒流量を制御するバルブ。

耐冷媒性、組付け性等が求められる。

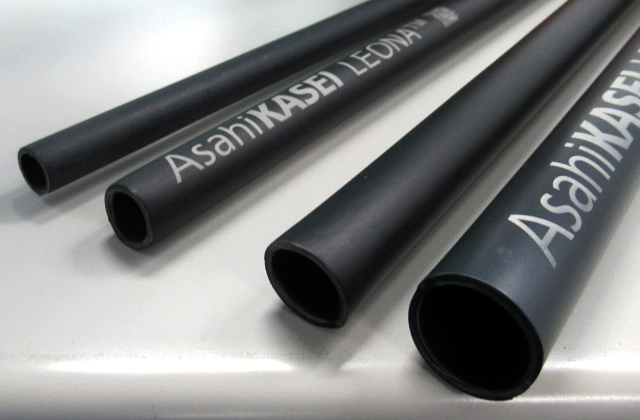

バッテリーEVの熱マネジメントのための各種冷媒を各ユニットへと繋げる配管・パイプ・チューブ。

押出成形で製造され、成形性、加工性、耐溶媒性等が求められる。

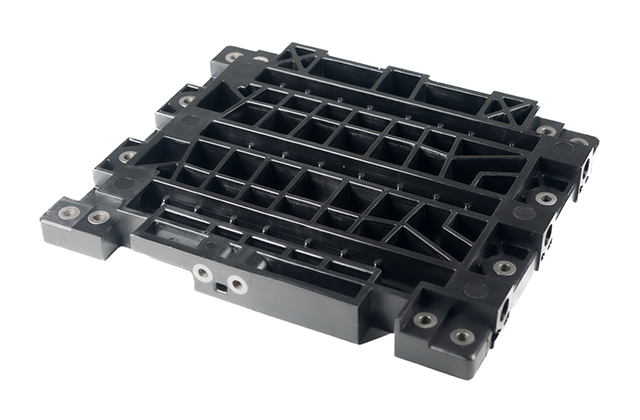

EVバッテリーモジュールの両端面で、バッテリーセルを押付・固定する部品。

バッテリーセルを強固に保持するため、非常に高い強度・剛性が求められる。

48Vマイルドハイブリッド車のバッテリーケースの樹脂化。

落下衝撃試験合格のために、樹脂CAEシミュレーションによる形状提案と高い機械強度を備えるレオナSGシリーズを組み合わせた事例。

エンジンユニットに装着される防振装置を取り付けるためのブラケット。

エンジンを支える防振装置を取り付けるため、高い強度と耐疲労性が求められる。

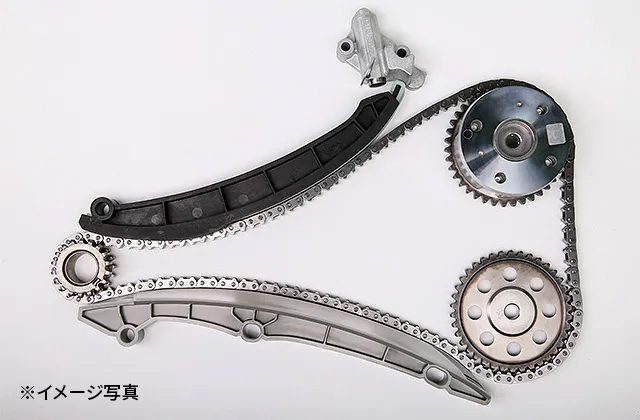

自動車エンジンタイミングチェーンのサポート部品。

駆動するチェーンに接するため、摩擦・摩耗特性が求められる。

:

:

1442、PFASフリー摺動グレード(開発品、詳細はお問い合わせください)

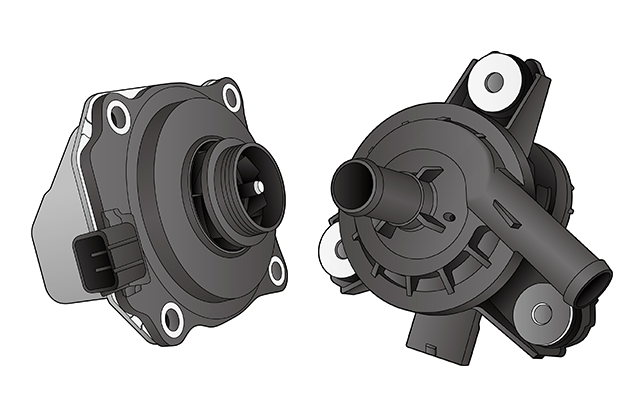

エンジン、ブレーキなどのオイルポンプ、バッテリーなどの冷却ポンプ。

液体と触れ続けるため、低吸水性・吸水時の低寸法変化・低物性変化が求められる。複数の成形品から成立するため、良成形性も求められる。

BG230

SG104

従来、アルミニウムなどの金属が用いられてきた、高い強度や耐久性が求められる自動車の連結部品。

自動車内部のドアハンドルおよびハンドル周辺のケース。

自動車内装部品では、VOC(揮発性有機化合物)量の基準値合格・耐光性・耐薬品性が求められる

Z4513

ZM413

シートベルトを外す時に押すバックル部分のボタン。

自動車内装部品に要求される耐候性、低VOC(揮発性有機化合物)性、非常時にも破損しにくい耐衝撃性が求められる

車に搭載される各種カメラに使用される鏡筒、レンズスペーサー。

光学部品を収納するため、高い寸法安定性が求められる。

XP640

DG040

車に搭載されるヘッドアップディスプレイ構成部品。

光学部品であり、高い寸法安定性が求められる。

※イメージ写真

※イメージ写真

リレー、ヒューズ等をまとめる接続箱・ケース。

リレー、ヒューズを組み込むため、良寸法、抜き差しの靭性等が求められる。

ギアは動力を伝達する重要な部品。自動車、産業機械、航空などの幅広い分野で使用されており、低摩擦性・耐摩耗性・耐熱性が求められる。

※イメージ写真

※イメージ写真

:

:

15G20、PFASフリー摺動グレード(開発品、詳細はお問い合わせください)

ベアリング保持器は転動体を保持する役割を果たし、滑らかな回転を助ける重要な部品。耐熱性・低摩擦性・耐摩耗性が求められる。

※イメージ写真

※イメージ写真

車載向けニッケル水素電池(NiMH)のケース。

耐電解液性、電極と接しても劣化しないこと等が求められる。

リチウムイオン電池(LiB)の製造及び輸送に用いるトレイ。セル製造・輸送時の安全のための高い難燃性が求められる。

ミリ波領域で電波透過性に影響を与える雪・氷を除去するための、融雪機能付きカバー。

※イメージ写真

※イメージ写真

BEVの電池パックの側部に組付け、側突時に変形することでエネルギーを吸収するパーツ。

※イメージ写真

※イメージ写真