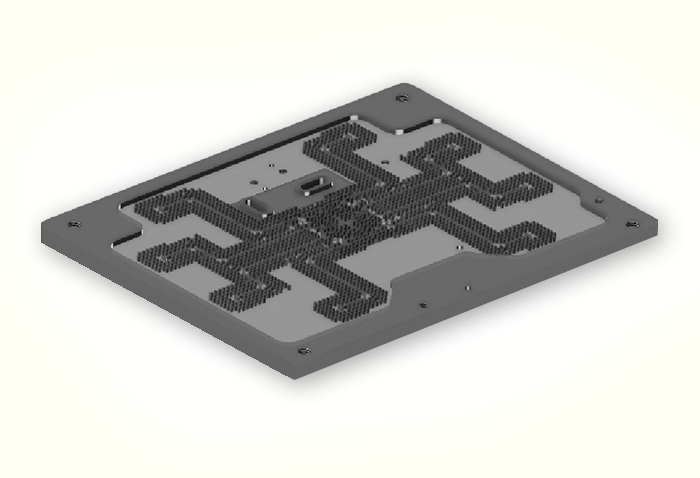

Low-cost automotive millimeter wave radar

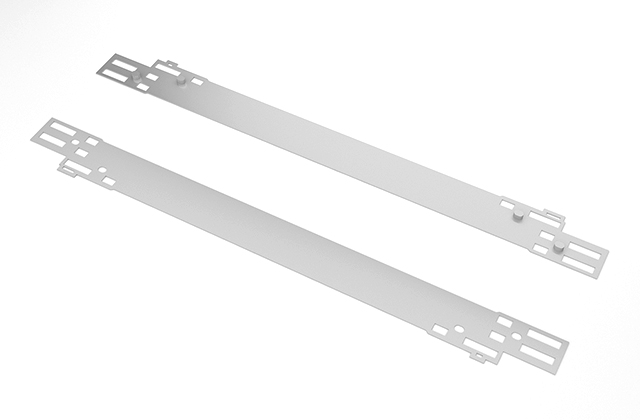

A highly directional, high-gain antenna used in radar and 5G/6G communications that reflects radio waves by arranging multiple slots in a waveguide. High dimensional accuracy, lightweight, and good plating properties are required.

Product