Technologies and Products

Materials for Gap waveguide slot array antennas (low cost, high dimensional stability, good plating)

XP650 (AA105-52) / DG040

XP650 (AA105-52) / DG040

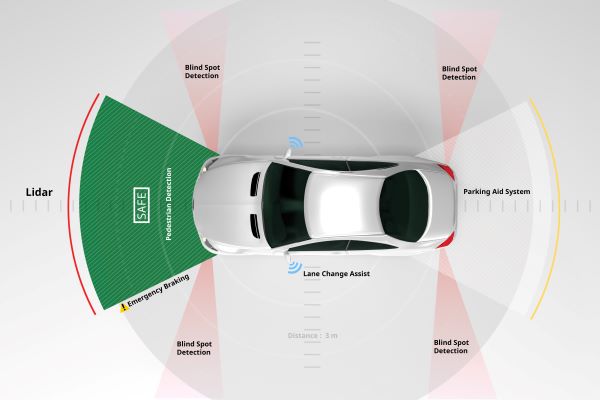

Gap waveguide slot array antennas are millimeter-wave band antennas that typically have a structure where multiple slot antenna elements are provided in a metal waveguide to operate as an array antenna. These antennas have recently been considered for applications such as ADAS due to their high performance.

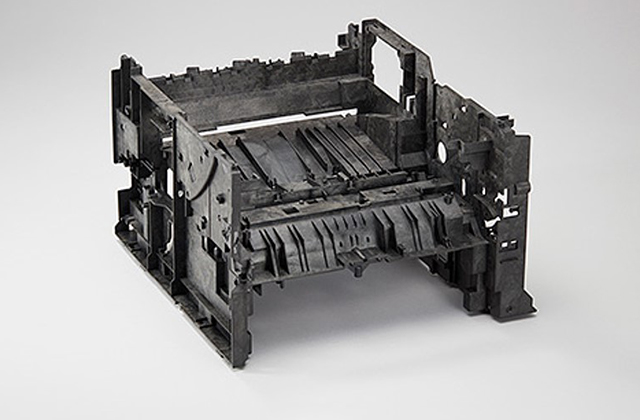

Asahi Kasei and the Hirokawa Laboratory at Institute of SCIENCE TOKYO (formerly Tokyo Institute of Technology) are working to reduce the weight and manufacturing costs of Gap waveguide slot array antennas by forming the waveguide out of metal-plated XYRON™ XP650 (AA105-52).

XYRON™ XP650 (AA105-52) and XYRON™ DG 040 have high heat resistance and a stable low coefficient of linear expansion over a wide temperature range, making them suitable for resinifying metal parts that require high precision, such as gap waveguide slot array antennas.

User benefit of XYRON™ Gap waveguide slot array antennas are below.

- Improved antenna performance by using air as a waveguide, which has the lowest dielectric constant compared to the conventional microstrip type.

- Reduction of processing cost by injection molding + plating compared to metal cutting (CNC machining).

- Lightweight (40% lighter than aluminum)

- Better dimensional stability and shape reproducibility than other resins (PPS), contributing.

| Antenna Type | Microstrip | Waveguide Slot (Metal) |

Waveguide Slot (XYRON™ + plating) |

Waveguide Slot (PPS+Plating) |

|---|---|---|---|---|

| Cost | ○ | × | ○ | × |

| Weight | ○ | × | ○ | △ |

| Performance | × | ○ | ○ | △ |

| Dimensional stability | – | ○ | ○ | × |

| Plating | – | ○ | ○ | × |

| Property | Units | Test method | Test condition | XYRON™ | PPS+GF40 | |

|---|---|---|---|---|---|---|

| XP650 (AA105-52) |

DG040 | |||||

| Specific Gravity | – | JIS K7112 | 23℃ | 1.56 | 1.52 | 1.66 |

| DTUL | ℃ | ISO 75-1 | 1.8MPa | 253 | 188 | >260 |

| CLTE(MD/TD) | ×10^-5 mm/mm/℃ |

ISO 11359 | -30~65℃ | 1.5/2.8 | 2.2/3.1 | 1.5/4.5 |

| Molding Shrinkage(MD/TD) | % | ASAHI KASEI method |

150×150×2㎜ | 0.17/0.22 | 0.28/0.34 | 0.30/0.67 |

| Tensile Strength | MPa | ISO 527-2 | 23℃/50%RH | 122 | 66 | 165 |

| (Nominal) Tensile Strain | % | ISO 527-2 | 23℃/50%RH | 2 | 2 | 3 |

| Flexural strength | MPa | ISO 178 | 23℃/50%RH | 175 | 103 | 253 |

| Flexural modulus | MPa | ISO 178 | 23℃/50%RH | 12,810 | 9,500 | 15,000 |

| Charpy Impact Strength | kJ/m² | ISO 179 | 23℃/50%RH | 4 | 2 | 9 |

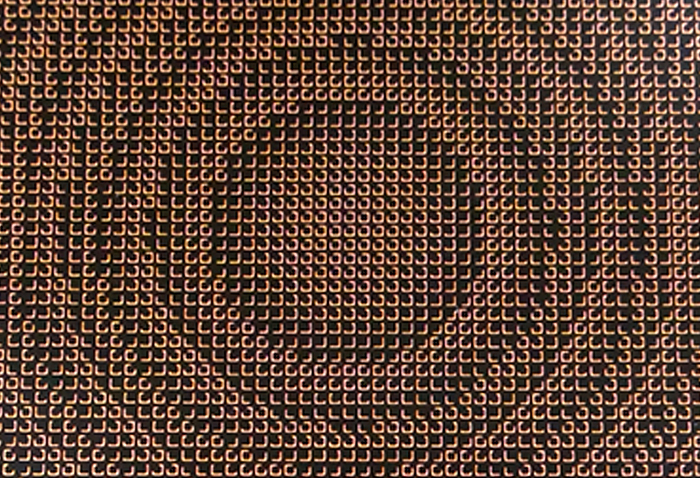

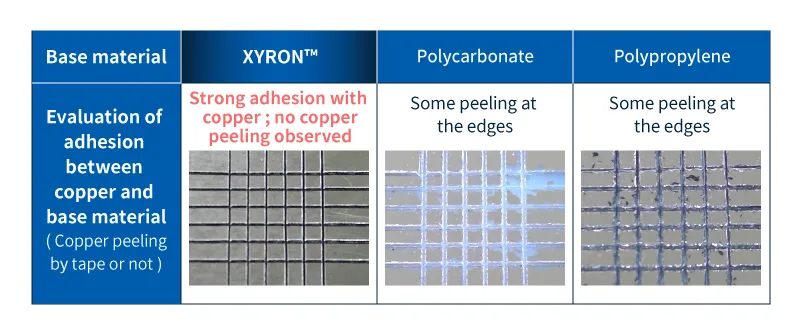

In addition, XYRON™ has excellent plating properties and adheres better to copper than other materials such as polycarbonate and polypropylene, as shown in the evaluation results below.

Compared to PPS, which is generally considered difficult to plate, the plating process for XYRON™ requires less processing costs, which translates into cost benefits for the product.