Product

Excellent heat resistance, strength and toughness, insulation, and oil resistance. It is widely used in automotive parts, electrical and electronic parts.

For inquiries regarding SDS and various chemical substance investigations, please make your request through your purchasing route, such as via a trading company.

We appreciate your understanding and cooperation.

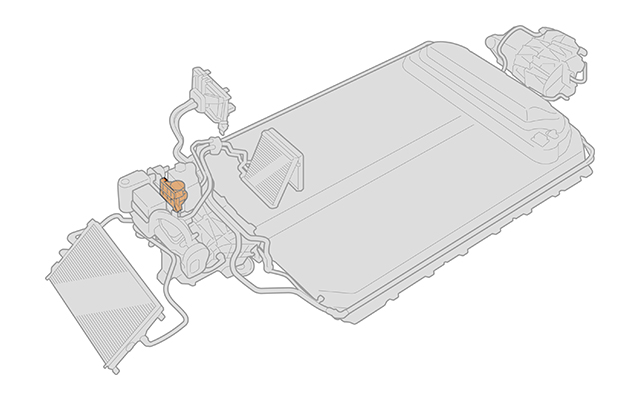

All around the world—and especially in Europe and China—the automobile industry is in the midst of a rapid transition from conventional gasoline-fueled vehicles to battery electric vehicles (BEVs). In BEVs, the gasoline engines in conventional vehicles are replaced by three primary modules: a motor, a battery, and an inverter.

Although BEVs are more energy-efficient than engine-powered vehicles, their batteries can store only limited quantities of energy, and thus the motors and batteries of BEVs must operate with high efficiency to ensure satisfactory performance. The temperature of these components tends to increase when in use, and strategies for offsetting these increases—to maintain each component within its optimal operating temperature range—are crucial for increasing energy efficiency and extending travel distances. Such strategies are known as a thermal management technology. Historically, thermal management systems for BEVs were typically implemented separately for each individual functional unit in isolation—one for the battery, another for the powertrain, and a third for the air conditioning, each operating independently from the others—but more recent vehicle designs have begun to address thermal management as a system-wide challenge demanding unified, comprehensive solutions.

Asahi Kasei offers both innovative material products and advanced technical support services to assist in developing the broad range of products required for ever-evolving thermal management systems.

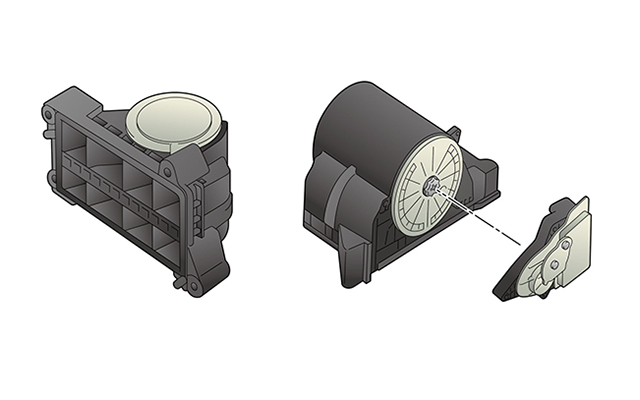

Asahi Kasei’s LEONA™ polyamide resin is an engineering plastics featuring high strength, high rigidity, high heat resistance, and outstanding chemical resistance. These materials may be further strengthened by reinforcing them with glass fibers or similar fillers, improving their strength, rigidity, durability, and dimensional stability.

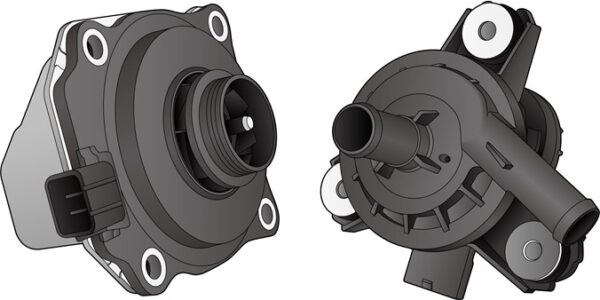

As one example, LEONA™ 14G30 is a material with a proven track record of successful adoption for valves in thermal management systems. To help our customers take full advantage of the superior physical properties of this material—including its high strength, resistance to long-life coolants, and excellent laser-welding and laser-marking characteristics—Asahi Kasei offers extensive technical support services: our experienced engineers work together with customers to accelerate product development and achieve innovative solutions.

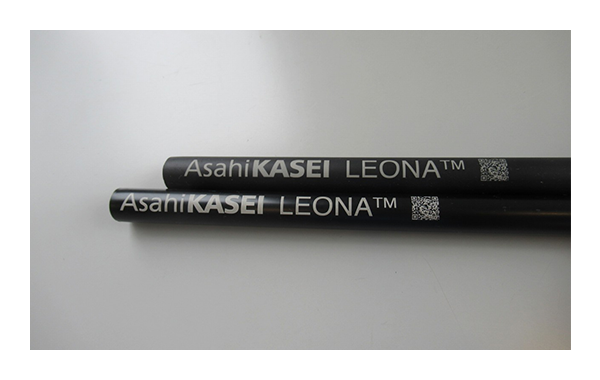

Asahi Kasei offers a variety of materials and processing techniques for pipes used for various purposes. Pipes are typically made from metals (such as aluminum alloys) or from metals in combination with rubber materials. Replacing these metals with resin materials yields lighter-weight products at lower cost.

Below, we review some common techniques for forming materials into pipes.

WIT is a specialized injection molding used to produce pipes and other hollow bodies. The technique begins by filling a mold with molten resin, as in conventional injection molding, but then a stream of water is injected through the center of the mold. Water injection is delayed until the resin near the outer pipe surface has cooled and solidified, while resin near the center of the pipe remains molten and is readily displaced by the water stream to yield a hollow pipe. Although this method is only recommended for relatively short pipes (on the order of 50 cm), it is capable of forming branched pipes and pipes with cross-sectional deformation or non-uniform diameters, making it a good choice for branched and curved pipes in cooling systems.

In this method, a resin material is heated beyond its melting point and extruded from a die to yield a contiguous body with a uniform cross-sectional shape.This technique is capable of producing tubes and pipes with small diameters and long lengths. In addition, the extruded bodies can be processed to yield complex configurations of interconnected pipes, with applications including cooling pipes for battery packs and interconnects between functional units such as radiators, battery packs, and motors.

Asahi Kasei offers LEONA™ extrusion grade PA612 resin for the cooling piping of the above water-cooled thermal management systems.

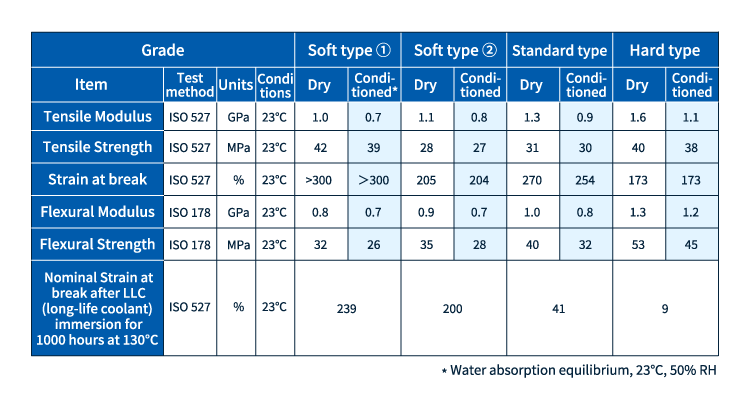

PA612 has characteristics such as flexibility, hydrolysis resistance, heat aging resistance, and chemical resistance, making it an ideal material for cooling piping.

Note: The values in this table are typical values obtained by established test methods, and are not guaranteed. This information is provided for reference to assist in identifying suitable material grades for specific applications. Values may change due to improvements in material properties. Physical properties of mass-produced products may differ from those of prototypes or product samples.

LEONA™ BG230 polyamide resin is a material based on the biomass plastic PA610, which contains 60% plant-based polymers.

PA610 exhibits lower water absorption than PA66, ensuring good dimensional stability even when used in environments subject to water exposure. This material offers excellent chemical and calcium chloride resistance, and exhibits good laser-welding characteristics, making it a suitable choice for cooling pumps with reduced size and weight.

LEONA™ SG104 polyamide resin is an alloy grade made from semi-aromatic polyamide and polyamide 66.

This material exhibits low dimensional variation and degradation of physical properties upon water absorption. Its key features include high specific strength, attractive appearance, and excellent fluidity.Compared to polyphenylene sulfide (PPS), a material commonly used for these applications, LEONA™ SG104 generates less gas during injection molding and exhibits better moldability.

SunForce™ is Asahi Kasei’s family of XYRON™-based foam materials that combine the unique lightweight and thermal-insulation characteristics of foams with superior properties—far beyond the capabilities of conventional foams—as a result of the use of modified polyphenylene ether (m-PPE) ingredients. These properties include excellent flame retardance (UL-94 V-0), dimensional precision, and suitability for fabricating thin-walled components.

The foamy structure of SunForce™ beads means that this material contains less resin than solid materials—and, as a consequence, fewer pathways for heat to flow through the material, ensuring low thermal conductivity and high thermal insulation.

The superior thermal-insulation properties of SunForce™ beads facilitate thermal management for EV batteries.

A well-known property of batteries is that their output falls dramatically at low temperatures. To avoid this behavior, various strategies have been devised for electric and high-output hybrid vehicles, involving heaters and other mechanisms, for keeping batteries at sufficiently high temperatures.

Asahi Kasei recommends insulating vehicle batteries with SunForce™ beads. This prevents batteries from releasing heat and cooling while the vehicle is at rest, preserving the battery’s high output power for hours with no need for a heater.

When heaters are present, the insulation provided by SunForce™ beads minimizes external thermal loss.

SunForce™beads also reduce the power used to cool batteries while driving by reducing the influx of external heat through the vehicle chassis. This improves heat-exchange efficiency and maximizes battery performance.

Also, SunForce™ materials are foams that may be used wherever flame-retardant behavior is required.

SunForce™ is the world's first particle foam beads material to receive the extremely high level of flame resistance "V-0" certification in the UL Flame retardance standard "UL-94" for plastics and components. In addition, due to its lightweight foam and self-extinguishing properties, it is already being considered for use in peripheral parts of EV battery packs.

For example, using SunForce™ beads for cell holders in vehicle-mounted battery packs offers the following advantages.

1.Improved safety: Use of foam materials with UL-94 V-0 flame retardance

2.Weight reduction: SunForce™ foams can reduce weight compared to injection-molded resin materials.(The specific gravity of 10x foam grades is 0.1 kg/L.)

For customers designing products based on Asahi Kasei’s engineering plastics, we offer a variety of technical support services based on our simulation capabilities.

For example, when attempting to replace metal with resin in parts such as valves, there are concerns about lack of strength and stiffness, and a decrease in strength of weld lines.

In this case, we use simulation technology to examine the shape and gate position, and carry out design and performance predictions to minimize the effects of weld lines and prevent breakage and leakage during use.

Please feel free to contact us with any questions about our products or technologies or to request samples.

We will introduce Asahi Kasei 's engineering plastic products and technologies in more detail.

We regularly deliver product and industry information to help you gather information.