Product

Excellent self-lubricating nature, fatigue behavior, and oil resistance. It is used in gears, bearings, automotive interiors and medical parts.

For inquiries regarding SDS and various chemical substance investigations, please make your request through your purchasing route, such as via a trading company.

We appreciate your understanding and cooperation.

PIM is a technique for manufacturing miniature high-precision metallic or ceramic components. In PIM, a metallic or ceramic powder is first blended with a binder, then injection molded, processed to remove binder components, and sintered.

PIM was developed in the U.S. during the 1970s as an advanced approach to powder metallurgy for manufacturing metal components; the technique combined conventional methods of powder metallurgy with injection-molding techniques for plastics. The traditional approach to powder metallurgy, known as press molding, involved inserting metal powders into molds and could only produce components with relatively simple shapes. In contrast, PIM fabricates metal components according to the same principles used in injection molding, allowing mass production of complex-shaped components.

Among the various types of resin used as PIM binders, polyacetal (also known as polyoxymethylene or POM) has a number of particularly valuable properties: it is easily processed, offers high dimensional stability and high mechanical strength, and exists as a crystalline resin with many physical properties that remain stable over a range of temperatures extending up to the melting point. These properties of POM make it the primary choice for injection modeling of precision resin components such as gears—and carry over directly to the PIM domain when POM is used as a binder.

Asahi Kasei offers suitable binder products for both catalytic debinding and thermal debinding in powder injection molding (PIM).

In addition to binder resins for catalytic debinding, we have developed an all-in-one binder suitable for heat degreasing in metal injection molding (MIM).

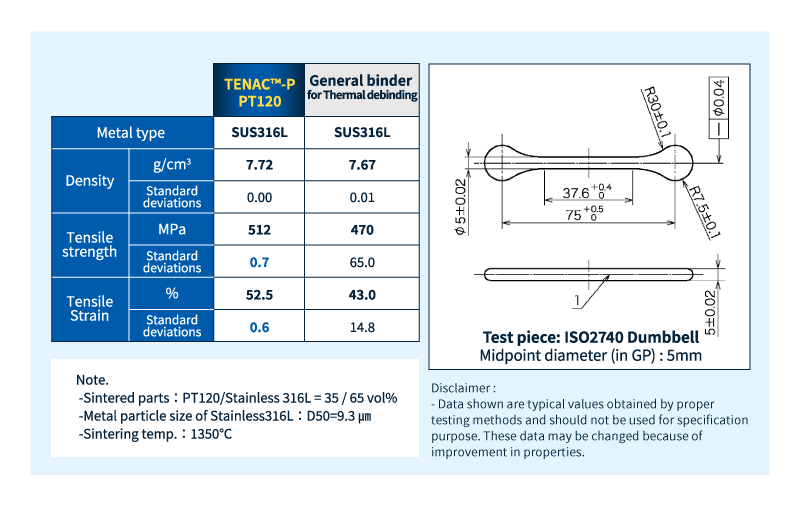

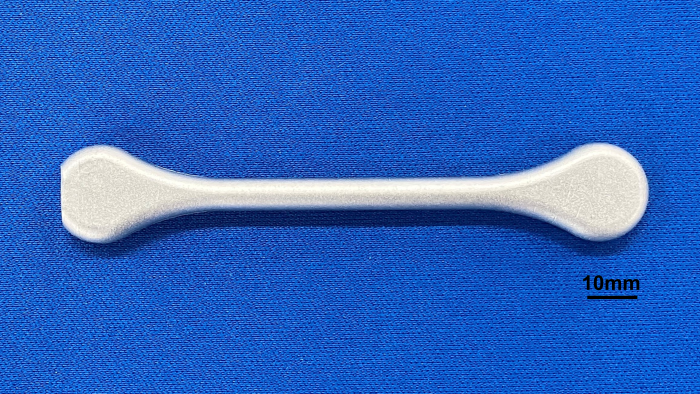

TENAC™-P PT120 is a grade developed as an All-in-one binder suitable for thermal debinding in metal injection molding(MIM).

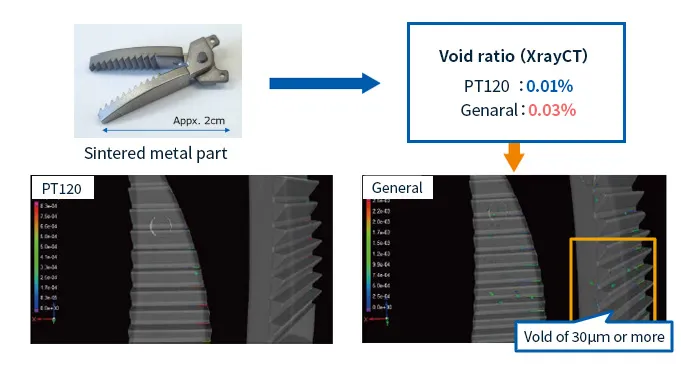

Using our alloying technology, multiple types of resins are aggregated and dispersed to reduce voids and residues in sintered parts.

This binder is suitable for thin shaped parts and medical parts.

As shown in the table below, sintered compacts made with TENAC™-P PT120 have high mechanical properties. High quality sintered compacts can be obtained with little variation in mechanical strength.

If you require more detailed information or samples of TENAC™-P TT120, please contact us from below.

TENAC™-C FF520 and FF52P are ultra-high fluidity polyacetal copolymers developed as binders suitable for catalytic debinding in powder injection molding (PIM).

Polyacetal (POM) is commonly used as a resin constituent of PIM binders due to the high strength of POM itself and its ability to decompose with no residue under application of acid or heat.

TENAC™-C FF520 and FF52P combine the superior mechanical properties of POM with the advantage of ultra-high flow.

General Properties of TENAC™-C FF520 and FF52P and each resin

| Item | Test Methods | Unit | TENAC™-C FF52P |

TENAC™-C FF520 |

TENAC™-C 7520 |

HDPE* | PP* |

|---|---|---|---|---|---|---|---|

| Meltmass flow rate (190℃, 2.16kg) |

ISO 1133 | g/10min | 120 | 120 | 30 | 40 | 75 (at 230℃) |

| Density | ISO 1183 | g/cm3 | 1.41 | 1.41 | 1.41 | 0.96 | 0.90 |

| Melting point | DSC | ℃ | 165 | 165 | 165 | 133 | 162 |

| Incineration residue | TGA 500℃, under N2 |

% | 0 | 0 | 0 | 0.5 | 0 |

| Modulus of elasticity in tension | ISO 527-1 | MPa | 2840 | 2840 | 2800 | 1000 | 1400 |

| Elastic modulus in bend | ISO 178 | MPa | 2810 | 2810 | 2600 | 1000 | 1300 |

| Charpy impact strength (notched) |

ISO 179 | kJ/m2 | 3 | 3 | 5 | 2.5 | 2 |

| Deflection temperatureunder load (0.45MPa) |

ISO75 | ℃ | 156 | 156 | 156 | 67 | 100 |

| Shape | – | – | Powder d50≒500㎛ |

Pellet | Pellet | Pellet | Pellet |

| emarks | Ultra-high flow | Ultra-high flow | Ultra-high flow | Reference value | Reference value |

*Indicates the reference values for the grades used in PIM.

We hope you will consider Asahi Kasei’s FF520 / FF52P as ideal match for your design needs. For more information, please refer to the slides available from the download link below. TENAC™-C FFF520 / FF52P as ideal match for your design needs. For more information, please refer to the slides available from the download link below.

TENAC™-C FF520 / FF52P Download Slides

Please feel free to contact us with any questions about our products or technologies or to request samples.

We will introduce Asahi Kasei 's engineering plastic products and technologies in more detail.

We regularly deliver product and industry information to help you gather information.