Technologies and Products

For inquiries regarding SDS and various chemical substance investigations, please make your request through your purchasing route, such as via a trading company.

We appreciate your understanding and cooperation.

2025.06.17

Technologies and Products

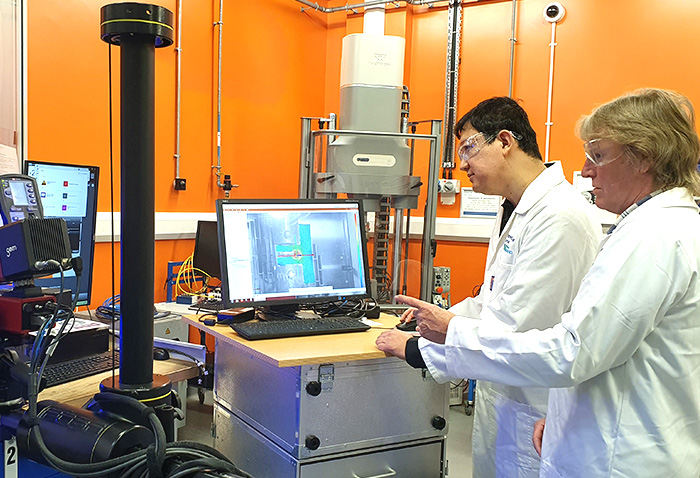

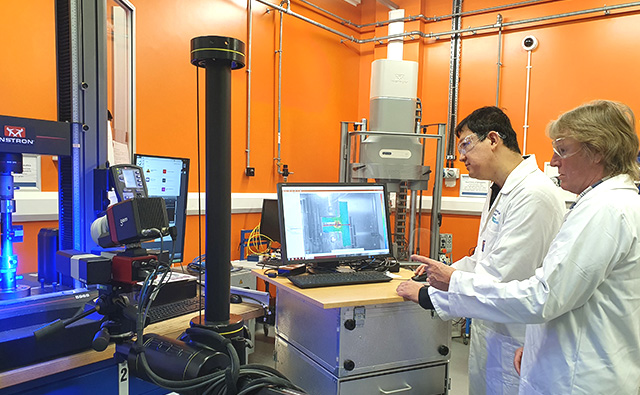

In Asahi Kasei, we develop our CAE techniques for metal replacement with our engineering plastics to design more lightweight components . By incorporating the fracture mechanics parameters in our FE simulations, our new CAE techniques successfully achieved more accurate prediction of maximum failure load of components compared to conventional methodologies, leading to more lightweight and reliable component designs. To keep developing our CAE abilities, we have collaboration research projects with Imperial College London (ICL, UK). An overview of this research project in ICL is introduced in this page.

Injection-moulded (IM) short-fibre reinforced thermoplastics (SFRPs) are lightweight materials suitable for high-volume applications; however, current FE simulation methods for those components cannot yet accurately predict failure, based on failure initiation criteria. This work presents a methodology to predict failure of IM-SFRP subcomponents accurately, based on experimentally measured fracture mechanics parameters using cohesive zone modelling (CZM).

*citation:Paper ①,②

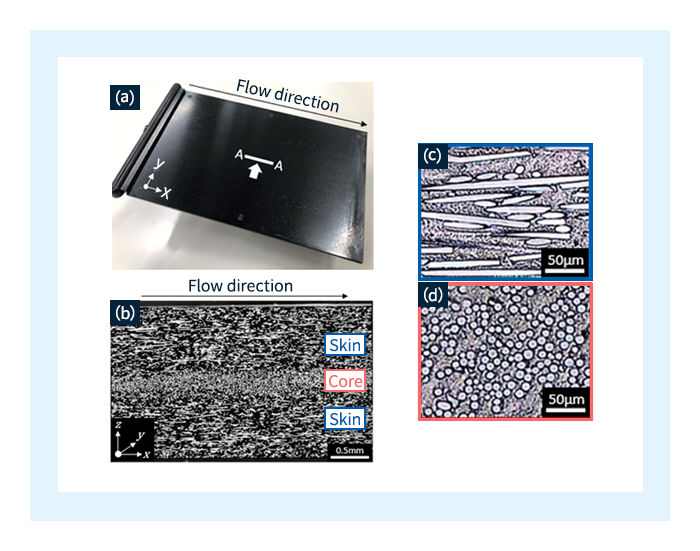

In this research, IM-plates shown below were manufactured, and used for the material characterisation. In IM-SFRPs, the fibres align along the flow direction near the mould surface. This fibre alignment leads to the change of the mechanical properties depending on the testing angles (anisotropy). The details of this anisotropy are explained in 「Part 9 Orientation in fiber-reinforced plastic」.

Fig. 1 Injection-moulded plates(a), cross-sectional image observed at A-A line(b), higher magnification in skin(c), and higher magnification in core(d) *citation:Paper ①,②

Fig. 1 Injection-moulded plates(a), cross-sectional image observed at A-A line(b), higher magnification in skin(c), and higher magnification in core(d) *citation:Paper ①,②

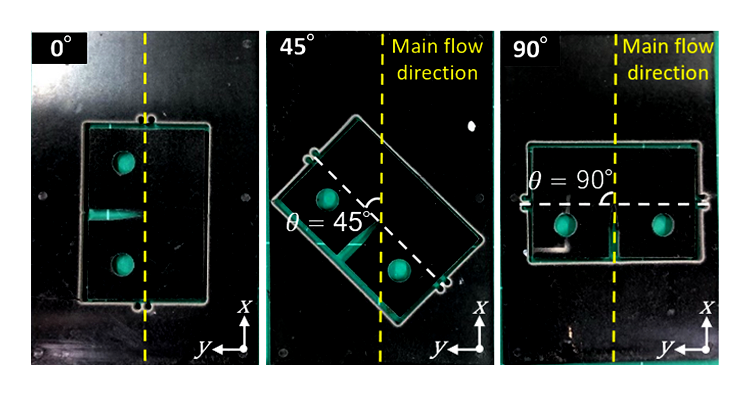

Strain energy release rate of IM-SFRPs was measured through Compact Tension (CT) testing. The CT specimens shown Fig.2 were machined from the IM-plates at several angles, and tested by applying the load through continuous quasi-static displacement control of the loading pins shown in Figure 3. In this test, stable crack propagation was seen from the initial crack tip.

Fig. 2 CT specimens machined at several angles *citation: Paper 1

Fig. 2 CT specimens machined at several angles *citation: Paper 1

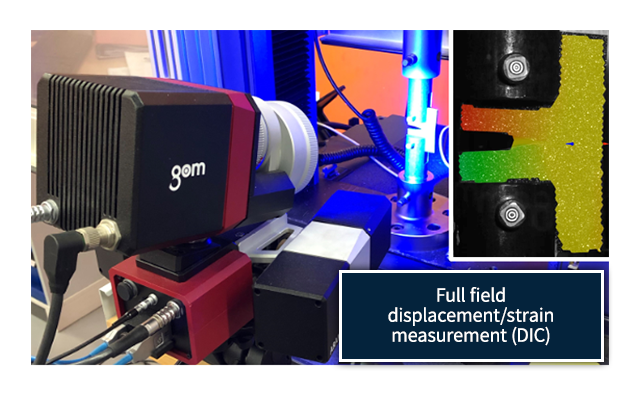

Fig. 3 CT testing set-up

Fig. 3 CT testing set-up

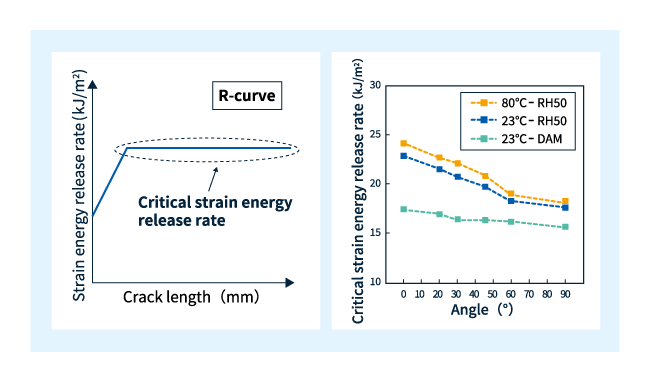

The obtained test results were transformed into R-curves, and the plateau region of the curve was used as critical strain energy release rate of the material. These strain energy release rates were influenced not only by the fibre orientation states but also by the testing temperatures and moisture conditions. The details of the testing methodology and the data reduction process are described in our journal paper (Paper ①).

Fig. 4 Example of R-curve and summary of angle-dependent strain energy release rates *citation:Paper ①

Fig. 4 Example of R-curve and summary of angle-dependent strain energy release rates *citation:Paper ①

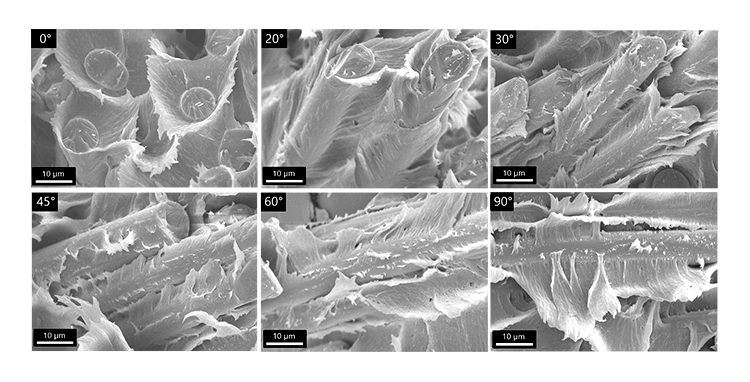

Fracture surfaces of CT specimens after the testing were observed using SEM. In 0° direction, it showed fibre failure with matrix plastic deformation, then shifting to matrix shear failure in the 45° direction, and to matrix transverse tension failure in 90° direction. We believe these changes of the damage mechanisms are closely related to the increase/decrease in strain energy release rates.

Fig. 5 Fracture surfaces of CT specimens at several angles after CT testing *citation:Paper ①

Fig. 5 Fracture surfaces of CT specimens at several angles after CT testing *citation:Paper ①

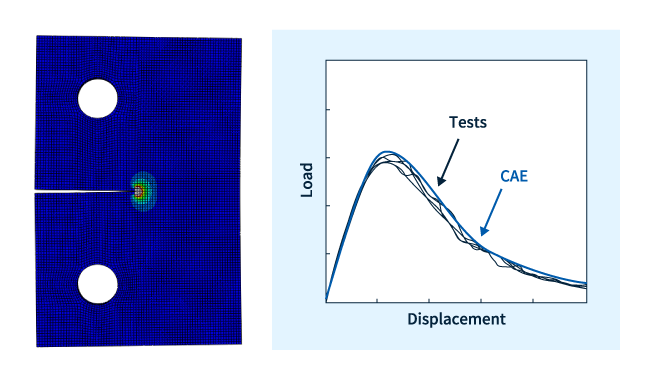

FE simulation of the CT test was conducted and the output was compared with the test results. The parameters used in our FE simulation (CZM) were calibrated with experimentally-measured strain energy release rates. In this result, our FE simulation showed excellent agreement of initial stiffness, peak load and the post-peak behaviour compared to the test results.

Fig. 6 Comparison of the load-displacement curves of CT tests from CAE and experiments *citation:Paper ①

Fig. 6 Comparison of the load-displacement curves of CT tests from CAE and experiments *citation:Paper ①

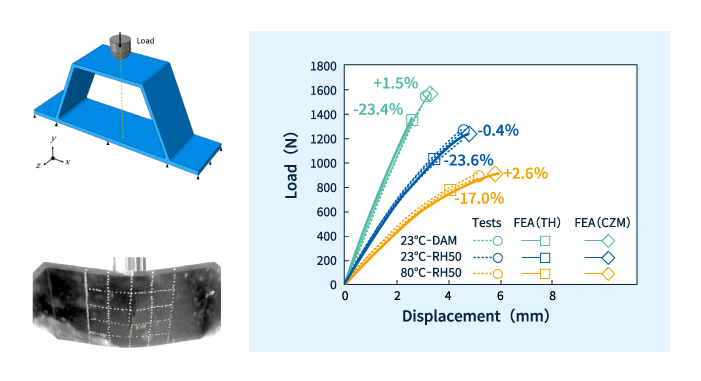

he subcomponents shown below were manufactured, and tested through quasi-static indentation. The figure (right) shows the load-displacement curves of the subcomponent tests from FE simulations and experiments. Failure initiation criterion available in commercial software (Tsai-Hill (TH) criterion in this example) under-predicted the maximum failure load by about 20%, while FE simulations using CZM (calibrated with experimental strain energy release rates) showed excellent failure prediction within 3% error compared to the tests. This result indicates that our CAE technique is promising to predict failure accurately, to design more lightweight and reliable components.

Fig. 7 Geometry of the subcomponents, the location of crack initiation and FE simulations for the prediction of maximum failure load using Tsai-Hill or CZM *citation:Paper ②

Fig. 7 Geometry of the subcomponents, the location of crack initiation and FE simulations for the prediction of maximum failure load using Tsai-Hill or CZM *citation:Paper ②

The output from this research has been published in prestigious journals and presented in international/Japanese conferences, as described below.

① “Initiation and propagation fracture toughness of injection-moulded short fibre composites under different environmental conditions” (2023) (https://doi.org/10.1016/j.compscitech.2022.109891)

Authors:Yuki Fujita1,2,3, Satoshi Noda1, Junichi takahashi2, Emile S. Greenhalgh3, Soraia Pimenta3,

② “Predicting failure in injection-moulded short-fibre subcomponents under varied environmental conditions through fracture mechanics” (2024) (https://doi.org/10.1016/j.compositesb.2024.111343)

Authors:Yuki Fujita1,2.3, Satoshi Noda1, Junichi takahashi2, Emile S. Greenhalgh4, Soraia Pimenta3,

Affiliation:

1. CAE Development Department, Sustainable Polymers Laboratory, Asahi Kasei Corporation

2. CAE Technical Department, Production Technology Centre, Asahi Kasei Corporation

3. Department of Mechanical Engineering, Imperial College London

4. Department of Aeronautics, Imperial College London

・International Conference on Composite Testing and Model Identification (2021)

・European Conference on Composite Materials (2022)

・Materials Tech Day (2023)

・International Conference on Composite Materials (2023)

・ECCOMAS COMPOSITES 2023 (2023)

・Japanese Conference on Composite Materials (2024) *Best presentation award

・European Conference on Composite Materials (2024)

・Japanese Conference on Composite Materials (2025)

Please contact us to ask any questions, discuss any concerns, and request samples.

Please feel free to contact us with any questions about our products or technologies or to request samples.

We will introduce Asahi Kasei 's engineering plastic products and technologies in more detail.

We regularly deliver product and industry information to help you gather information.