- TOP

- Basic knowledge engineering plastics

- What are PFAS?

What are PFAS?

PFAS regulations, their impact, and substitute materials.

1. What are PFAS?

PFAS is a general term for per- and polyfluoroalkyl substances, and PFAS is defined as a fluorine compound that contains at least one fully fluorinated methyl or methylene group (with no hydrogen, chlorine, bromine, or iodine attached). There are a large number of chemical substances that fall under PFAS, with 4,730 types according to the OECD and 14,735 types according to the US EPA *1. Although the properties vary depending on the type, they have excellent properties such as chemical resistance, heat resistance, water repellency, and insulation, and are used in a very wide range of applications from households to industries.

*1: Navigation Panel to PFAS Structure Lists (EPA)

2. PFAS regulations

Concerns over the effect of some types of PFAS on the environment and human health have resulted in continuously evolving regulatory trends. Regulatory frameworks are being discussed and established by the United Nations and in Europe, some states in the United States, and other countries worldwide. Two major activities in this area are: (1) the United Nations Stockholm Treaty (Persistent Organic Pollutants: POPs), and (2) EU trends.

(1) United Nations Stockholm Treaty (POPs)

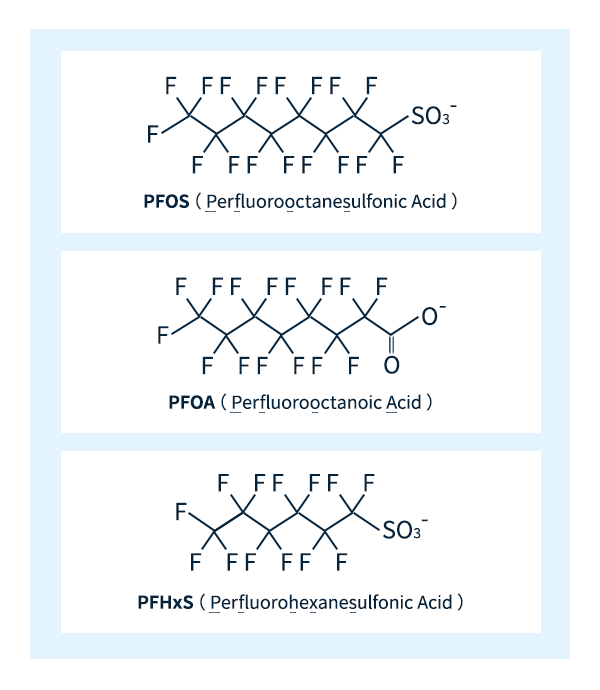

- Of the more than 10,000 types of PFAS, three types - PFOS, PFOA, and PFHxS - are subject to restrictions on production and use in countries that have ratified the treaty due to their persistence, accumulation, and toxicity. *2

- In Japan, it is designated as a Type 1 specified chemical substance under the Chemical Substances Control Law.

- These three types of PFAS are defined as "specific PFAS" by the Japan Fluorochemical Products Council *3.

- Long-chain perfluorocarboxylic acids (LC-PFCAs) are also being considered for regulation. *2

- Fluorocarbon polymers and fluorine rubbers such as PTFE and PFA, which are widely used in society, are not subject to the POPs regulations.

*2: POPs Convention (Ministry of Economy, Trade and Industry)

*3: Specific PFAS (Japan Fluorochemical Products Council)

Molecular structure of PFOS, PFOA, and PFHxS

Molecular structure of PFOS, PFOA, and PFHxS

(2) EU trends

- The European Chemicals Agency (ECHA) is currently considering proposals to restrict the use of PFAS.

- These proposals are based on the important concept of taking protective measures while the risk and severity of PFAS remain unclear. Restrictions are therefore being established even for applications for which no substitutes are currently available.

- As of January 2024, the PFAS regulation is expected to be discussed and adopted by the European Parliament as early as 2025. There will be an 18-month transition period after adoption, but for applications where there are no alternatives yet and it will take time to develop alternatives, a grace period of 5 or 12 years has been set (please see here *4 for details on applications).

- It is possible that polymers considered non-hazardous at present will also fall within the scope of the restrictions, so developments in this area are being closely monitored.

- ECHA invited public consultation in 2023 and expects discussions to proceed based on a summary of all stakeholder opinions. (As developments regarding this regulation are ongoing, the situation may change.)

*4:ANNEX XV RESTRICTION REPORT (ECHA)

3. PFAS substitutes

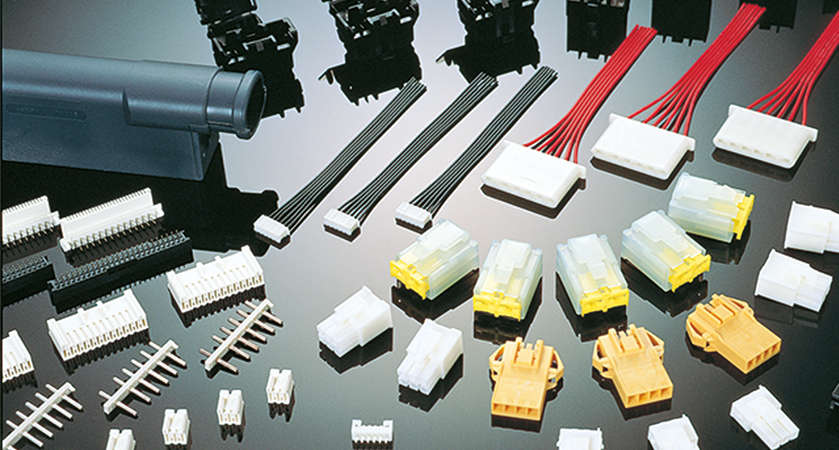

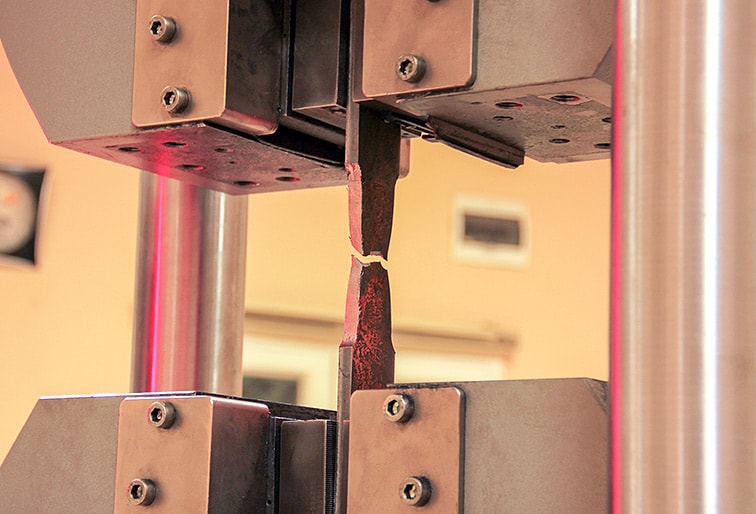

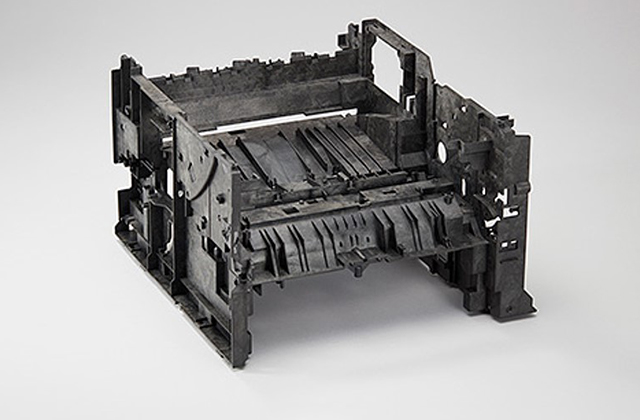

The PFAS (most PFAS other than “Specified PFAS”) currently used for a variety of applications supporting our day-to-day lifestyle exhibit many outstanding attributes such as heat resistance, chemical resistance, sliding properties, and electric properties. Substitutes with exactly the same performance as these PFAS are almost non-existent, and potential candidates must match the applications and reasons for using PFAS when being considered. For example, it is possible to use resins such as polyoxymethylene (POM) for applications where good sliding properties are critical, but these would need to be considered on a product-by-product basis due to their inferior heat resistance. PFAS are also sometimes used almost unnoticed as additives to enhance sliding properties and flame retardance. In such cases, it is necessary to select PFAS-free materials that exhibit similar properties.

(Written by Isao Sato, Isao Sato Technical Office)

We welcome your inquiries about PFAS substitutes.

Asahi Kasei offers PFAS-free engineering plastics to match your application and objectives.

Please feel free to contact us with any questions, inquiries, or sample requests.

Please contact us to ask any questions, discuss any concerns, and request samples.