- TOP

- Sustainability

- 製品を使う

Sustainability

Using products

Contents

Summary

- By selecting and using products that use resources efficiently, we can contribute to resource conservation and sustainability.

- Asahi Kasei offers Materials that improve the energy efficiency of products during use and extend their lifespan.

Use products that contribute to resource conservation

By selecting and using products that use resources efficiently, we can contribute to resource conservation and sustainability.

We introduces materials that improve energy efficiency during product use and extend product life.

Improving energy efficiency during product use

■ Improved fuel efficiency and reduced load during transportation due to weight reduction

In general, the lighter the vehicle and other transportation equipment, the less energy it takes to run, resulting in better fuel efficiency and the ability to run more and longer with the same fuel and energy capacity. In other words, weight reduction can contribute to reducing CO2 emissions.

In addition, by using lighter materials, it is possible to lighten the load weight during product transportation and reduce the energy required for transportation.

■ More efficient heat management

Electric vehicles, which are expected to become more popular in the future, do not have a heat source, unlike engine-powered vehicles, so it is extremely important to properly manage heat (heat management) without wasting heat. Therefore, it is possible to reduce heat loss and reduce energy consumption by using materials with heat insulating properties and utilizing heat recovery technology.

Product life extension

Making long-lasting, high-quality products reduces waste due to failure or damage during use, which leads to reduced consumption.

In order to prolong the life of the product, the use of materials with excellent durability and heat resistance suitable for the environment and usage of the product will extend the life of the product and ultimately contribute to resource conservation. increase.

Asahi Kasei’s Recommended Solutions (1)

Solutions for reducing product weight

Weight reduction of in-vehicle batteries

With countries around the world declaring a switch to electric and hybrid cars, which are said to emit less CO2, the presence of automotive secondary batteries is increasing, but at the same time their weight is becoming a major issue. .

Therefore, by incorporating engineering plastics into the design of automotive secondary batteries, it is possible to contribute to weight reduction.

Asahi Kasei has more than 10 years of experience in the manufacture of high-performance engineering plastics for automotive batteries. For example, Asahi Kasei 's modified PPE resin "XYRON™" is widely used in the cells and structural components of automotive secondary batteries due to its halogen-free Flame retardance and low specific gravity, which reduces the amount of resin used. As an "environmentally-friendly product" of the Asahi Kasei Group, it contributes to reducing CO2 emissions at the product usage stage.

- Go here for details on "Materials for automobile batteries"

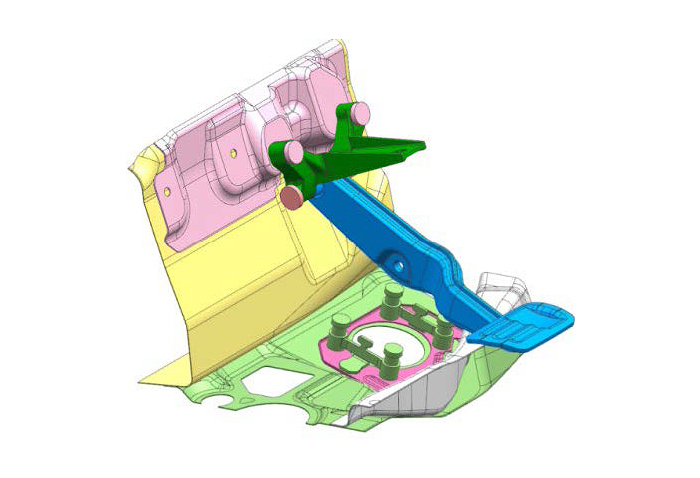

Weight reduction by replacing metal to plastic & optimizing parts design through the use of resin CAE

Metal replacement is the act of replacing a metallic component with a similar component made of plastic.

The case study presented here explored a proposal to redesign an existing metal product using plastic materials. A consideration of designs incorporating the results of multiple topology optimizations succeeded in reducing the weight by more than 60% compared to the original metal product; although this exceeded the original goal of 40% weight reduction, it involved an exceedingly complicated mold design, so we attempted to search for further improvements. An additional round of topology optimizations revealed that some portions of the redesigned product were superfluous, and saving these portions simplified the shape of the product and greatly facilitated the mold design—and, as an additional bonus, achieved a weight reduction of more than 80%, far surpassing the original goal.

Applying CAE techniques to product design can reduce weight, save space, and facilitate molding processes. Moreover, using less material helps achieve mass production at extremely low cost.

- Go here for details on "Asahi Kasei engineering plastics and CAE that realize the conversion of metal parts to resins (substitute for metal)"

Asahi Kasei’s Recommended Solutions (2)

Reduce product weight to lessen the environmental impact of shipping

XYRON™ modified PPE resins for automotive secondary batteries and solar-power generation

Asahi Kasei’s XYRON™ modified polyphenylene ether (PPE) resins are non-halogen, flame-retardant engineering plastics whose low specific gravity reduces resin usage and help to achieve sustainability goals. This material offers many excellent properties, such as dimensional stability, mechanical strength and hydrolysis resistance, and has become a common choice of material for automotive secondary battery cells and structural components, helping to undergird the explosive growth of electric vehicles.

The outstanding electrical properties and tracking resistance of XYRON™ resin have also earned this material a role in high-voltage solar-power generation systems. The use of plastics with outstanding tracking resistance for high-voltage systems allows miniaturization of products and helps to reduce resource usage. The low specific gravity of these materials also reduces CO2 emissions during shipping.

For these reasons, Asahi Kasei has solicited advice from third-party institutions regarding viewpoints and computation methods to assess environmental impact from the standpoint of life-cycle analysis (LCA), and has received internal certification as environmental contribution products.

- Go here for details on “Materials for photovoltaic, solar-power generators, with excellent weather resistance”

Asahi Kasei’s Recommended Solutions (3)

Solutions for thermal insulation, improving cooling and heating efficiency

SunForce™ modified PPE foam beads offer excellent thermal insulation, heat resistance, and flame retardance

SunForce™ foams combine the excellent properties that only foams can offer—light weight and thermal insulation—with flame retardance (UL-94 V-0), dimensional stability, and the ability to form products with thin walls. The result is a foam material offering functionality far beyond the capabilities of conventional foams. The foamy structure of SunForce™ beads means that this material contains less resin than solid materials—and, as a consequence, fewer pathways for heat to flow through the material, ensuring low heat conductance and thus high thermal insulation.

A well-known property of batteries is that their output falls dramatically at low temperatures. To avoid this behavior, electric vehicles and high-output hybrid cars have devised various strategies, involving heaters and other mechanisms, for keeping batteries at sufficiently warm temperatures. Asahi Kasei recommends insulating vehicle batteries with SunForce™ beads which may prevent batteries from releasing heat and cooling while the vehicle is at rest, preserving the battery’s high output power for hours with no need for a heater. When heaters are present, the insulation provided by SunForce™ beads may minimize thermal losses to the outside. SunForce™ beads also reduce the power used to cool batteries while driving by reducing the influx of outside heat through the vehicle chassis. This improves heat-exchange efficiency and maximizes battery performance.

Asahi Kasei’s Recommended Solutions (4)

Product life extension

Extending the life of water supply and drainage equipment

The excellent mechanical properties and friction/abrasion properties of polyacetal (POM) resin make it a good choice of material for mechanical components such as gears and axle bearings. Asahi Kasei’s TENAC™ MG210 POM homopolymer is not reinforced by glass fibers or other fillers; instead, Asahi Kasei’s crystal-control technology enables this product to exhibit good mechanical properties and excellent creep resistance, making it an ideal material for gears designed to operate under heavy loading, such as in mechanisms for raising and lowering glass windows in cars.

- Go here for details on Materials for water supply and drainage systems

Non-reinforced, highly durable polyacetal (POM) resins based on Asahi Kasei’s crystal-control technology can help to extend product lifetimes

The excellent mechanical properties and friction/abrasion properties of polyacetal (POM) resin make it a good choice of material for mechanical components such as gears and axle bearings. Asahi Kasei’s TENAC™ MG210 POM homopolymer is not reinforced by glass fibers or other fillers; instead, Asahi Kasei’s crystal-control technology enables this product to exhibit good mechanical properties and excellent creep resistance, making it an ideal material for gears designed to operate under heavy loading, such as in mechanisms for raising and lowering glass windows in cars.

In particular, the fatigue properties and creep resistance of TENAC™ MG210 are not only superior to those of other general-purpose engineering plastics, but even outperform standard POMs (copolymers) and Asahi Kasei’s previous generations of high-durability POMs (homopolymers). We recommend to choose TENAC™ MG210 which may extend the lifetime of your products—and may help achieve other goals as well: miniaturizing gears and other components, reducing product weight by replacing metal with plastic, and decreasing the component count.

Please contact us to ask questions and request samples. We look forward to hearing from you!