- TOP

- Basic knowledge engineering plastics

- What is CCC?

What is CCC?

This page provides an overview of the CCC system as well as CQC system and clarifies the differences between CCC and the often-confused CQC (China Quality Certification).

2025.12.02

What is CCC?

The China Compulsory Certification (CCC) is a mandatory conformity assessment system established by the Chinese government to ensure product safety, environmental protection, and compliance with national standards.

Products specified under this system—whether manufactured domestically or imported—must obtain CCC certification and bear the official CCC mark before they can be sold or distributed within China. Items lacking this certification are prohibited from entering, sold and or be distributed within the China market.

The CCC system is designed to safeguard consumer interests and align with international quality benchmarks by evaluating products against China national standards (GB standards). It applies to a wide range of goods, including:

- Home appliances

- Information technology equipment

- Automotive components

- Toys and children's products

By enforcing these requirements, the CCC helps ensure that products meet stringent safety and quality criteria, contributing to consumer protection and regulatory compliance.

*Information current as of December 2, 2025. Regulatory and certification requirements are subject to change, so please check with the relevant authorities or the latest official information for the latest information.

Official certification mark established by the China National Certification and Accreditation Administration (CNCA)

Official certification mark established by the China National Certification and Accreditation Administration (CNCA)

What is CQC?

CQC (China Quality Certification Center) is the largest CCC certification body in China. CQC is one of the largest certification bodies in China and is the main body that verifies CCC certification, but it also issues its own "voluntary certification (CQC certification)." This applies to general products that are not subject to CCC certification and products that wish to voluntarily demonstrate their quality.

In addition to its role in mandatory certification, CQC also offers its own voluntary certification, commonly referred to as CQC certification. This certification applies to products that are not subject to CCC requirements, or to manufacturers who wish to voluntarily demonstrate product quality and reliability in the Chinese market.

Voluntary CQC certification can enhance consumer trust, support marketing efforts, and serve as a competitive differentiator—especially for products aiming to highlight compliance with Chinese standards even when not legally required.

CQC (China Quality Certification Center) certification mark

CQC (China Quality Certification Center) certification mark

Differences and relationships between the two

Differences

- CCC Certification:A mandatory certification required by Chinese law. Products without CCC certification cannot be sold or distribute in the Chinese market.

- CQC Certification:A voluntary certification. It can be applied to products not subjected to CCC requirement or used as an additional quality mark to demonstrate product quality and or reliability.

- CQC Certification: A voluntary certification. It can be applied to products not subjected to CCC requirement or used as an additional quality mark to demonstrate product quality and or reliability.

Relationship

- CQC (China Quality Certification Centre) is one of the designated organizations responsible for carrying out CCC certification procedures.

- In addition to performing CCC mandatory certifications, CQC also conducts its own voluntary certification programs (CQC Certification), allowing manufacturers to choose the appropriate certification depending on their needs.

- In addition to performing CCC mandatory certifications, CQC also conducts its own voluntary certification programs (CQC Certification), allowing manufacturers to choose the appropriate certification depending on their needs.

- For certain product categories, certification schemes have shifted from CCC to CQC over time. The roles and requirements of both certifications may evolve as the regulations are updated.

Main test contents

CCC Mandatory Certification

- Test Standards:Based on the Chinese National Standards (GB Standards), including strict safety, quality, and environmental tests.

- Testing Laboratory:Type testing (sample testing) must be conducted by designated Chinese government-approved certification bodies and laboratories.

- Testing Laboratory: Type testing (sample testing) must be conducted by designated Chinese government-approved certification bodies and laboratories.

- Factory Inspection:On-site audits are required both during certification and at regular intervals to verify quality management and production processes.

- Marking:After certification, products and packaging must display the CCC mark.

- Renewal and Surveillance:Continuous follow-up inspections and audits are mandatory for maintaining certification.

CQC Voluntary Certification

- Test Standard:Evaluations are based on relevant GB standards or CQC’s own technical criteria, focusing on safety, quality, performance, and EMC (Electromagnetic Compatibility).

- Testing Laboratory: Type testing is conducted at CQC-approved laboratories. In some cases (Type II Voluntary Certification), self-testing or documentation-based declarations may be acceptable.

- Testing Laboratory: Type testing is conducted at CQC-approved laboratories. In some cases (Type II Voluntary Certification), self-testing or documentation-based declarations may be acceptable.

- Factory Inspection:Factory audits are generally required for initial certification but are usually less frequent and less strict compared to CCC.

- Marking: Products may carry the CQC mark as a sign of quality assurance, though displaying it is not legally required.

- Renewal and Surveillance:Certification renewal or follow-up audits may be requested, but requirements are generally less stringent than CCC.

Items subject to CCC certification and points to note

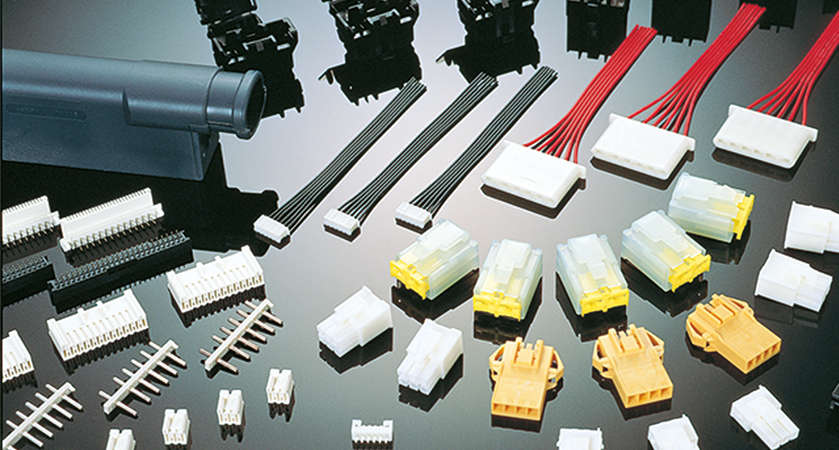

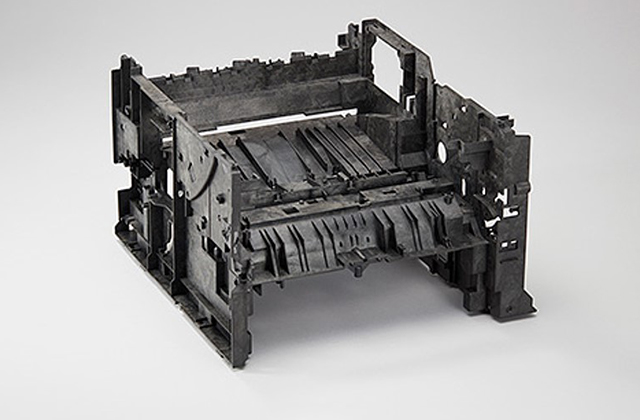

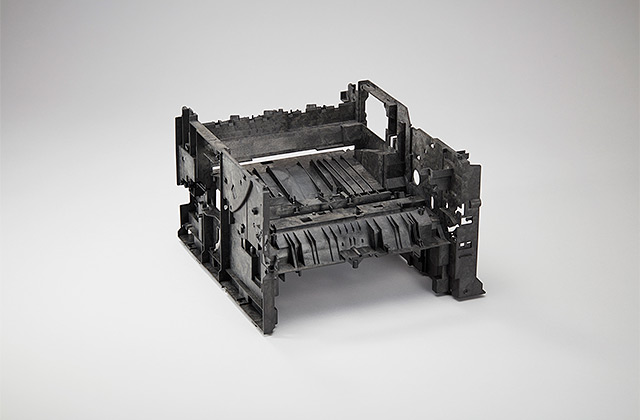

Major product categories subject to CCC include electrical wires and cables, low-voltage equipment, audio and video devices, IT equipment, automotive components, and toys.

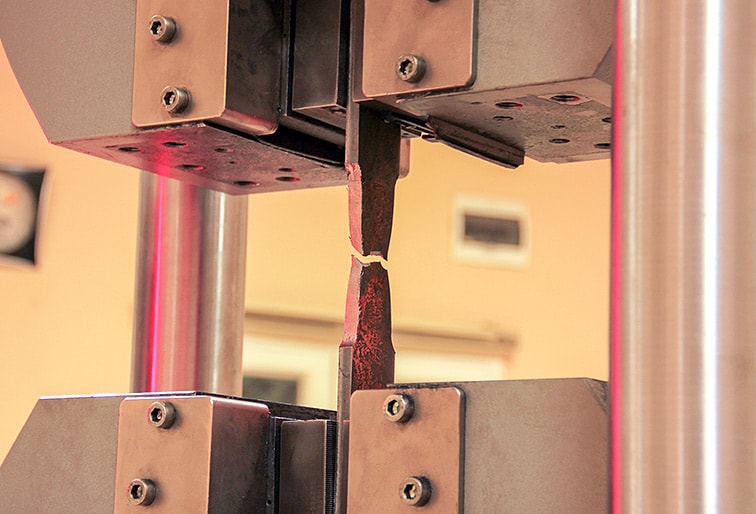

The main items covered include electric wires and cables, low-voltage equipment, audio equipment, AV equipment, IT-related equipment, automotive products, toys, adapters, printers, etc. Furthermore, the required standards for CCC certification list both V-0 and S2 tests (IEC-62368-1), and there is a possibility that regulations will become stricter in the future.

*Reference: Japan External Trade Organization (JETRO) China's Compulsory Product Certification System

TÜV (TÜV SÜD Japan) China CCC/CQC certified

JC (Japan Certification Co., Ltd.) Global Product Safety Certification Acquisition Support Service

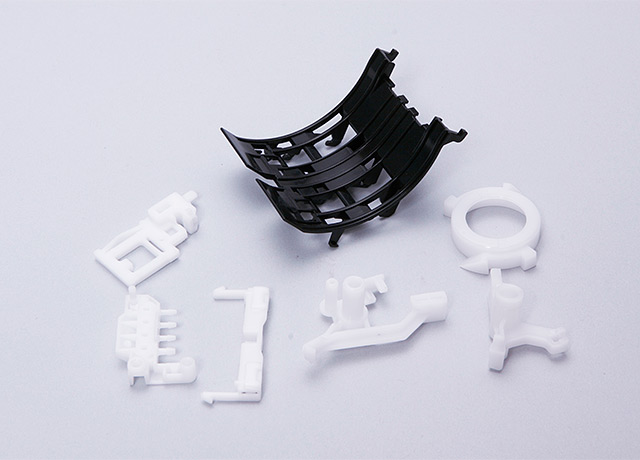

Contact Us for S2 Needle Flame Test Materials

Asahi Kasei offers engineering plastics that comply with the S2 test (IEC 62368-1) depending on the application and purpose. Please feel free to contact us with any questions, inquiries, or sample requests.

Asahi Kasei offers a wide range of engineering plastics that comply with S2 test (IEC 62368-1) requirements, tailored to various applications and performance needs.

For inquiries, consultation, or sample requests, please feel free to contact us.

→ [Link to OA Application Page]

Please contact us to ask any questions, discuss any concerns, and request samples.