Technical Information

Topology Optimization Details

Calculation of the optimal shape that maximizes performance under constraint

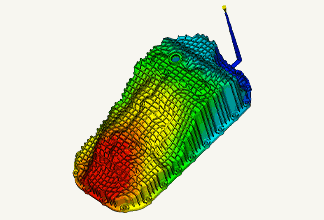

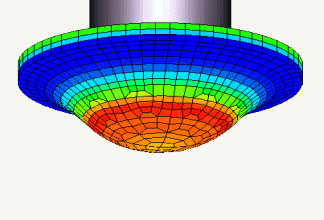

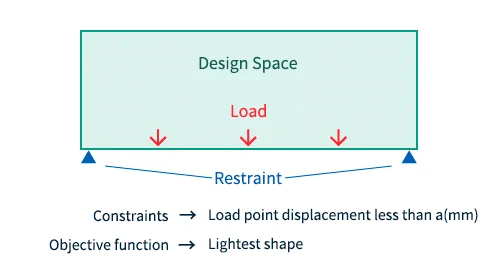

Here is a simple example of Topology optimization.

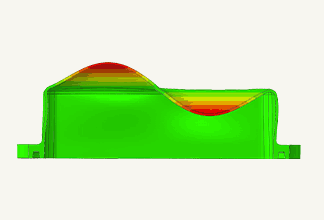

The green area in the diagram on the left is the design space. In this space, both ends are fixed and loads are applied to three points, and instructions are given to create the lightest shape with the displacement of the load points less than a (mm).

The process calculated using Altair Engineering's HyperWorks is shown in the figure on the right. The placement of materials is optimized by varying the density of each part in the design space. Red is the portion determined to be necessary and blue is the portion determined to be unnecessary. In this case, by devising the constraints, a steel bridge-like shape was calculated from 59 iterations of the calculation.

.png)