“Asahi Kasei Europe Battery Project”

Interviews

For inquiries regarding SDS and various chemical substance investigations, please make your request through your purchasing route, such as via a trading company.

We appreciate your understanding and cooperation.

PRESS RELEASE

2022.10.18

Press Releases

October 18, 2022

Asahi Kasei Corporation

Asahi Kasei Plastics Singapore Pte Ltd (APS), a wholly owned subsidiary of Asahi Kasei, acquired the widely recognized international certification ISCC PLUS*1 for its polyphenylene ether (PPE) as a sustainable product on September 19, 2022. Production of PPE using biomass-derived raw material is scheduled to begin in January 2023.

PPE is an engineering plastic that is blended with other resins such as polystyrene and polyamide to form modified PPE (m-PPE). Asahi Kasei’s XYRON™ m-PPE is widely used in automotive parts, consumer electronics, and industrial products.

XYRON™ features several excellent characteristics which are expected to drive further demand growth especially in the field of the environment and energy. For example, leveraging its excellent electrical insulation and other electrical characteristics, XYRON™ is used in parts for photovoltaic power generation systems which operate at high voltage. These excellent properties also allow products to be made smaller, which contributes to resource conservation. Furthermore, the low specific gravity of XYRON™ allows products to be made lighter, which contributes to the reduced CO2 emissions during shipment. XYRON™ is also used in components of batteries for electric vehicles (EVs), which are rapidly becoming widespread. Its low specific gravity and flame-retardancy allow batteries to be made lighter, which contributes to increased range and lower CO2 emissions.

As awareness for the global environment and the importance of sustainability increase, Asahi Kasei has worked to further raise the environmental contribution of XYRON™ m-PPE by using recycled raw material and biomass raw material.

Under these circumstances, Asahi Kasei and APS sought to reduce CO2 emissions across the supply chain for XYRON™ m-PPE, and in September 2022, APS became the first PPE manufacturer in Asia*2 to acquire ISCC PLUS certification. The certification enables APS to produce and sell PPE using sustainable raw material assigned by the mass-balance method*3. APS plans to produce PPE using sustainable raw material beginning in January 2023.

In order to contribute to carbon neutrality, Asahi Kasei is developing recycled grades of Xyron™ m-PPE which are made using recycled material, and working together with customers to establish a recycling scheme. PPE is a material suitable for recycling as its chemical structure has excellent hydrolysis resistance, which suppresses the deterioration of physical properties. Asahi Kasei also developed and patented technology to extend the service life of XYRON™ m-PPE, which further suppresses the deterioration of physical properties due to recycling.

The Asahi Kasei Group aims to be a global sustainable partner for its customers by contributing to the reduction of waste and CO2 emissions through the assignment of biomass in the PPE of its XYRON™ m-PPE by the mass-balance method, the development of products utilizing recycled material, and the establishment of a recycling scheme together with its customers.

*1 ISCC (International Sustainability and Carbon Certificate) is an international certification system that offers solutions for the implementation and certification of waste and residue raw materials, non-bio renewables and recycled carbon materials and fuels. ISCC PLUS is a certification system that covers mainly bio-based carbon materials which are produced outside of the EU and supply globally, and to manage and ensure sustainable raw materials in the supply chain.

*2 From the website in the ISCC as of October 11, 2022

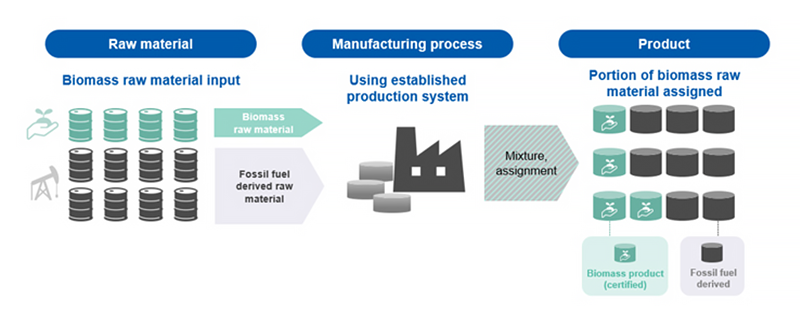

*3 In the case of a mixture of sustainable raw materials and fossil fuel-derived raw materials in the production process, the portion of sustainable product produced is assigned to certain products based on ISCC PLUS System Documents and its recognized management methods.

Mass balance method diagram

Mass balance method diagram

Please feel free to contact us with any questions about our products or technologies or to request samples.

We will introduce Asahi Kasei 's engineering plastic products and technologies in more detail.

We regularly deliver product and industry information to help you gather information.