“Asahi Kasei Europe Battery Project”

Interviews

For inquiries regarding SDS and various chemical substance investigations, please make your request through your purchasing route, such as via a trading company.

We appreciate your understanding and cooperation.

Significantly enhancing strength and durability, avoiding failure from weld lines

2024.07.10

Technologies and Products

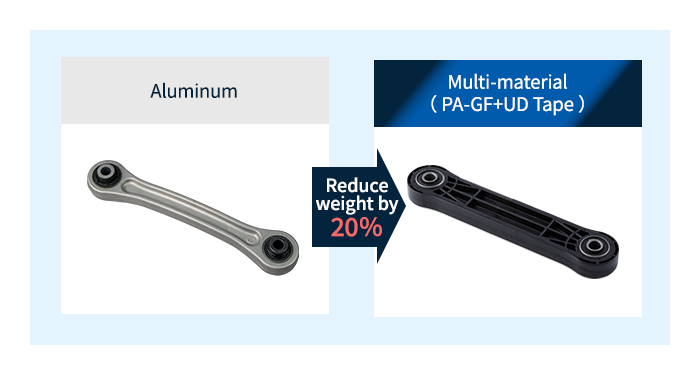

Asahi Kasei proposes a multi-material structure that integrates LEONA™ polyamide resin (PA-GF) and Uni-directional Tape (UD Tape) impregnated with polyamide resin to achieve significant weight reduction in automotive connecting parts (suspension arms) where high strength and durability are required.

Metal replacement for suspension arms using multi-material structure of LEONA™ polyamide resin + UD Tape

Metal replacement for suspension arms using multi-material structure of LEONA™ polyamide resin + UD Tape

The combination of LEONA™ polyamide resin with UD Tape offers several key advantages for connecting parts:

To predict the failure strength of resin-fabricated suspension arms, we conducted strength simulations, taking material anisotropy into account, at 80°C and 50% relative humidity to reflect the hot, humid environment in gasoline vehicles. The results, summarized in the table below, indicate that resin parts may exhibit lower compressive-failure strength but higher tensile-failure strength than aluminum parts. Resin-fabricated suspension arms are expected to boast even greater failure strength in electric vehicles, where the heating effects of exhaust emissions are absent.

【Results of strength simulations at 80°C and 50% relative humidity】

| Model | Tensile failure load (kN) |

Compressive failure load (kN) |

|---|---|---|

| Forged aluminum | 44.6 | 58.4 |

| PA-GF+UD Tape | 73.4 | 39.0 |

Note: Resin and UD Tape are treated as anisotropic materials in these simulations.

Asahi Kasei expects that this hybrid multi-material component will find applications not only in various types of automotive connecting parts conventionally made from aluminum or other metals (including suspension arms, motor mounts, torque rods, and stabilizer links) but also in structural backbones for products such as drones, robot arms, and personal mobility devices such as electric motorcycles.

A sampling of the many expected applications for Asahi Kasei’s hybrid multi-material component combining LEONA™ polyamide resin with UD Tape.

A sampling of the many expected applications for Asahi Kasei’s hybrid multi-material component combining LEONA™ polyamide resin with UD Tape.

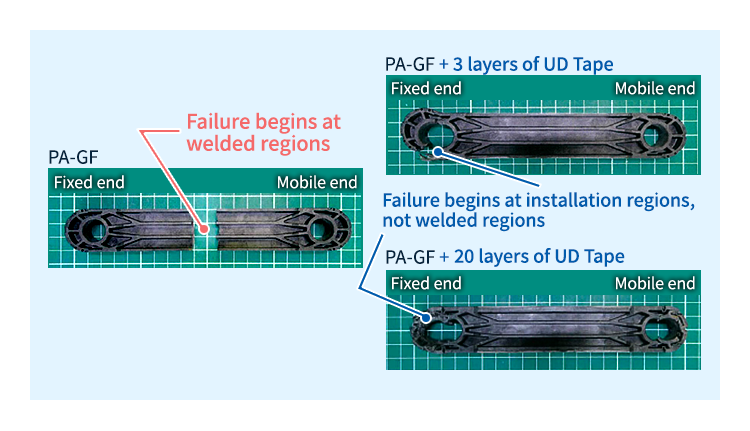

The strength-reinforcing effects of UD Tape prevent component failures caused by weld lines, which are defects resulting from the confluence of molten resin streams during the injection-molding process. This helps to increase strength and rigidity and disperse stress.

The strength-reinforcing effects of UD Tape ensure that, in tensile tests, component failure begins at installation regions, not welded regions.

The strength-reinforcing effects of UD Tape ensure that, in tensile tests, component failure begins at installation regions, not welded regions.

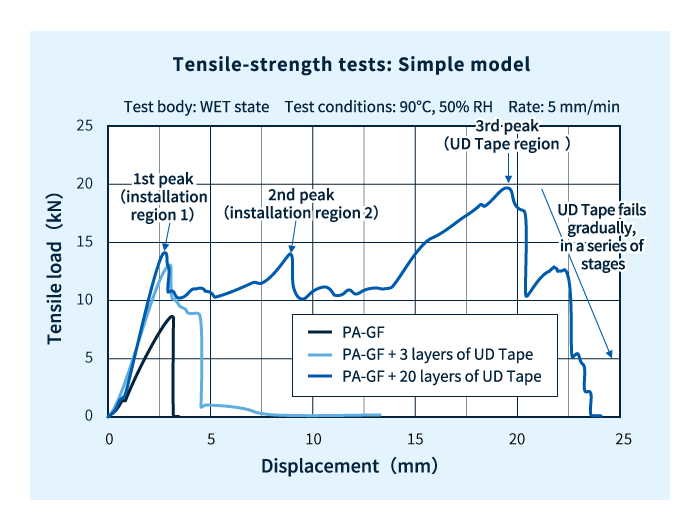

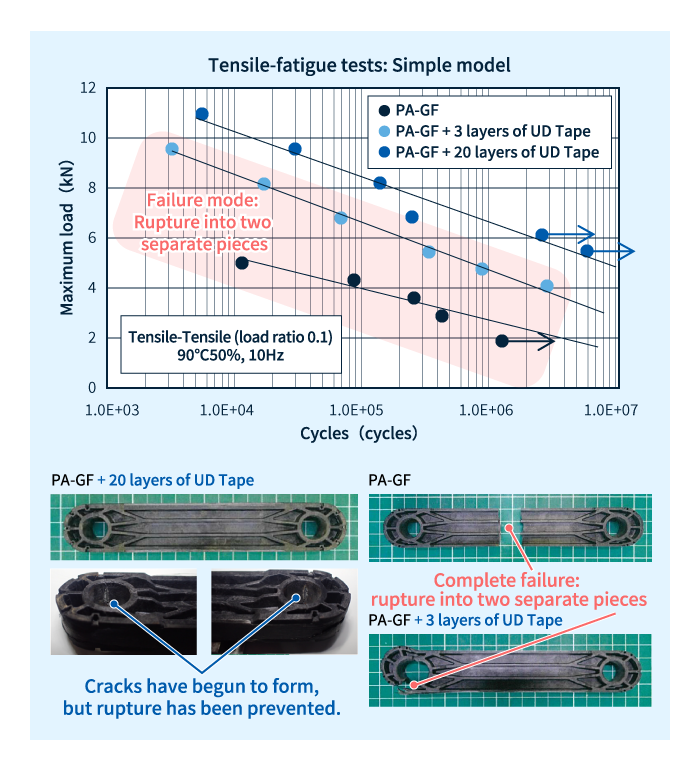

As shown in the graph below, a simple model indicates that automotive connecting parts made from a combination of LEONA™ polyamide resin and UD Tape offer significantly greater strength and durability than parts made from GF-reinforced PA resin alone.

Strength-reinforcing effects of UD Tape: Comparison of material performance in tensile-strength tests

Strength-reinforcing effects of UD Tape: Comparison of material performance in tensile-strength tests

Strength-reinforcing effects of UD Tape: Comparison of material performance in tensile-fatigue tests

Strength-reinforcing effects of UD Tape: Comparison of material performance in tensile-fatigue tests

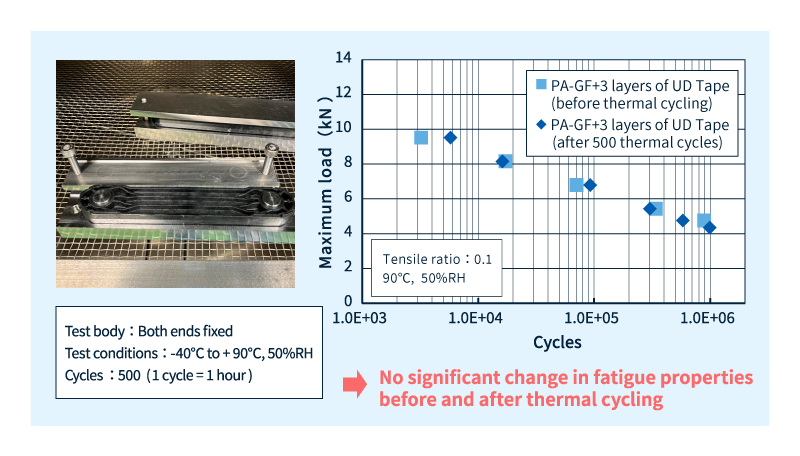

In addition, thermal-cycling tests (500 cycles, temperature range -40°C to +90°C, 50% RH) revealed almost no degradation in part-strength and almost no tendency for UD Tape to detach from parent materials due to differences in thermal-expansion rates.

Thermal-cycling tests

Thermal-cycling tests

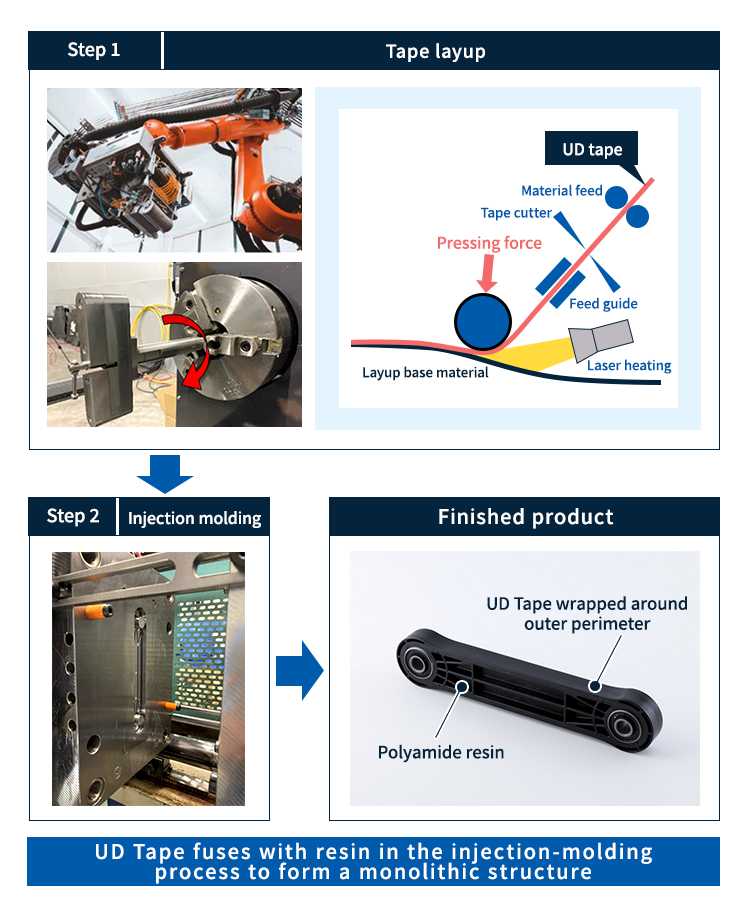

As illustrated below, UD Tape is pre-formed into a ring and installed inside the mold prior to molding; during the molding process, the UD Tape fuses instantaneously with GF-reinforced LEONA™ polyamide resin to yield a monolithic material structure. This manufacturing technique ensures highly efficient production.

Process for manufacturing hybrid multi-material parts from LEONA™ polyamide resin and UD Tape

Process for manufacturing hybrid multi-material parts from LEONA™ polyamide resin and UD Tape

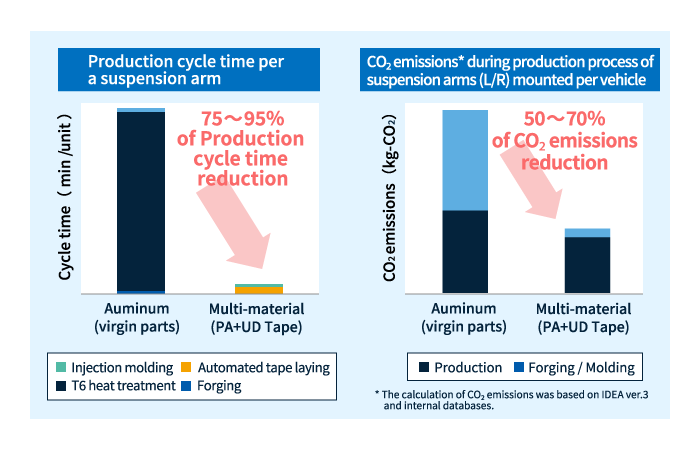

Manufacturing suspension arms in this way simplifies production processes and reduces process-control costs compared to forging parts from aluminum (virgin parts). This approach can also reduce CO₂ emissions from production processes by 50-70%.

Comparison of cycle time and CO₂ emissions

Comparison of cycle time and CO₂ emissions

If you are interested in our multi-material structure of LEONA™ polyamide resin + UD Tape as an alternative to metals for connecting parts that require high strength and durability, please feel free to contact us.

Please contact us to ask any questions, discuss any concerns, and request samples.

Please feel free to contact us with any questions about our products or technologies or to request samples.

We will introduce Asahi Kasei 's engineering plastic products and technologies in more detail.

We regularly deliver product and industry information to help you gather information.