Technologies and Products

For inquiries regarding SDS and various chemical substance investigations, please make your request through your purchasing route, such as via a trading company.

We appreciate your understanding and cooperation.

2025.07.04

Technologies and Products

Asahi Kasei has used a proprietary compound technology to blend and knead biomass polyamides with other specialized polyamides to develop a new PFAS-free, flame-retardant polyamide featuring low water absorption and high toughness.

Non-reinforced, flame-retardant resins—that are, resins that do not contain glass fibers or other inorganic substances—are widely used today for connectors, clamps, and other applications; however, such non-reinforced, flame-retardant resins often incorporate large quantities of additives to achieve flame retardance, thereby reducing toughness. In addition, the fluorine resins used as flame-retardant additives are classified as PFAS materials, and are thus increasingly subject to environmental regulations that may restrict their use in the future.

Our LEONA™ PFAS-free, low water absorption, highly toughness flame retardance polyamide (under development) is a next-generation unreinforced Flame retardance polyamide that combines high functionality with compliance with environmental regulations and can contribute to a wide range of applications.

Key features of LEONA™ PFAS-free, low water absorption, highly toughness flame retardance polyamide(under development) grades include the following.

Non-reinforced, flame-retardant resins tend to incorporate large quantities of flame-retardant substances, degrading their toughness. For products with parts that deform during the assembly process—such as hinges or snap-fit* junctions commonly used to make connectors or clamps—this reduction in toughness can result in products incapable of withstanding deformations without rupture.

*Snap-fit is a mechanical joining technique for mating metallic or plastic components that exploits material elasticity to yield junctions when components are pressed together.

Example of a snap-fit junction

Example of a snap-fit junction

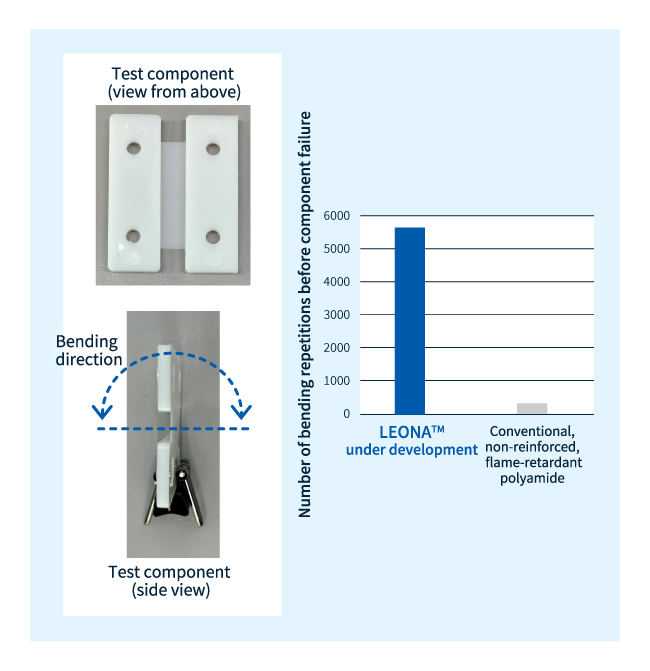

LEONA™ under development grade exhibit superior toughness, boasting durability more than 10 times greater than that of conventional, non-reinforced, flame-retardant polyamides in tests featuring repeated bending, as shown in this video.

Results of hinge tests

Results of hinge tests

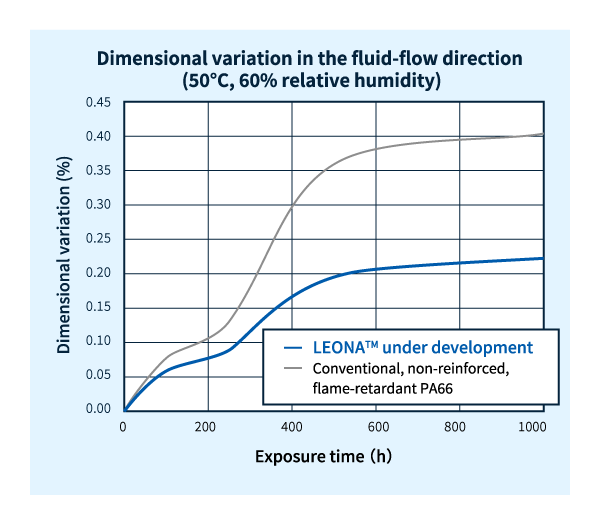

Conventional polyamides gradually absorb water from the surrounding atmosphere, causing variations in product dimensions. For maritime shipping and other applications featuring warm, humid operating environments, the amount of water absorbed increases and large variations in component dimensions tend to cause failures in product assembly. One material commonly selected to reduce water-absorption-induced dimensional variation is polybutylene terephthalate (PBT); however, PBT offers lower toughness than polyamides, and PBT components tend to break during product assembly. PBT is also susceptible to hydrolysis in warm, humid environments, significantly degrading strength compared to polyamides.

LEONA™ under development grade exhibits a water-absorption rate approximately one-half that of conventional, non-reinforced, flame-retardant polyamides, and also boasts excellent toughness and hydrolysis resistance compared to PBT. These advantages make this new material a candidate for components demanding high dimensional precision—an application for which polyamides and PBT have traditionally been difficult to use.

The figure below compares dimensional variation due to water absorption—in an application involving maritime shipping near the equator——for LEONA™ under development grades and for conventional, non-reinforced, flame-retardant materials. We have also confirmed the superiority of this new resin relative to conventional polyamides in an even more severe operating environment: 85°C with 85% relative humidity.

For detailed data, please contact us via the form below.

Comparison of dimensional stability in a warm, humid environment

Comparison of dimensional stability in a warm, humid environment

If you would like more detailed information, please contact us using the form below.

Please feel free to contact us with any questions about our products or technologies or to request samples.

We will introduce Asahi Kasei 's engineering plastic products and technologies in more detail.

We regularly deliver product and industry information to help you gather information.