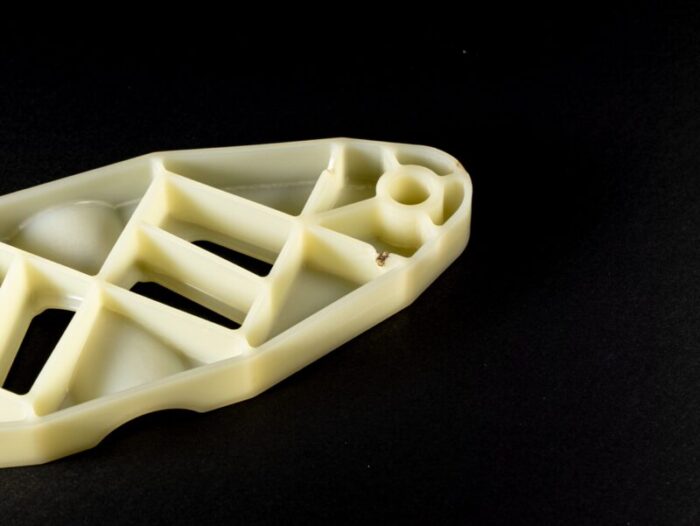

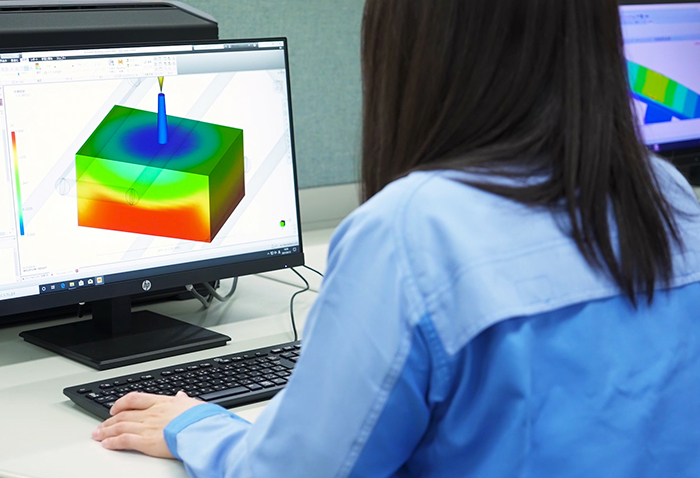

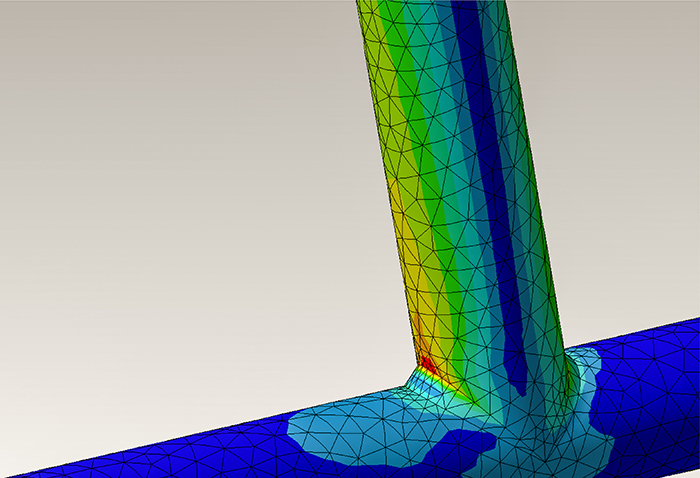

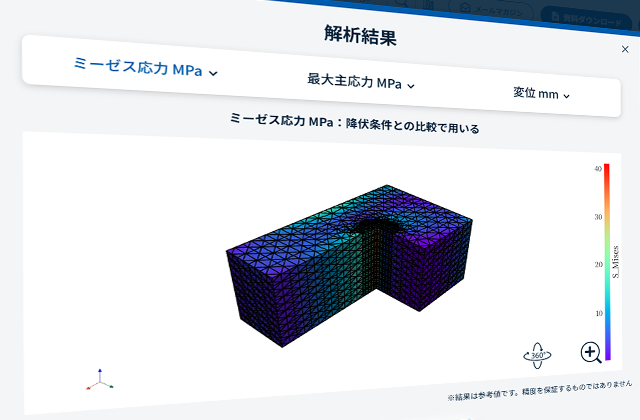

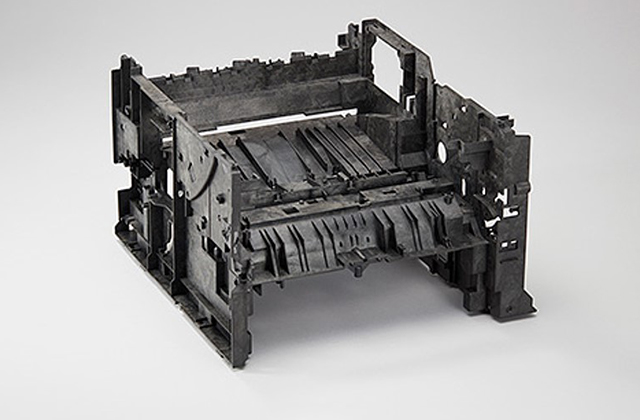

Topology optimization is an innovative technology that accelerates the design process, eliminates waste, and derives optimal shapes. This Topology optimization introduces the basic concepts and methods of Topology optimization for those who have not yet used it.