Technical Information

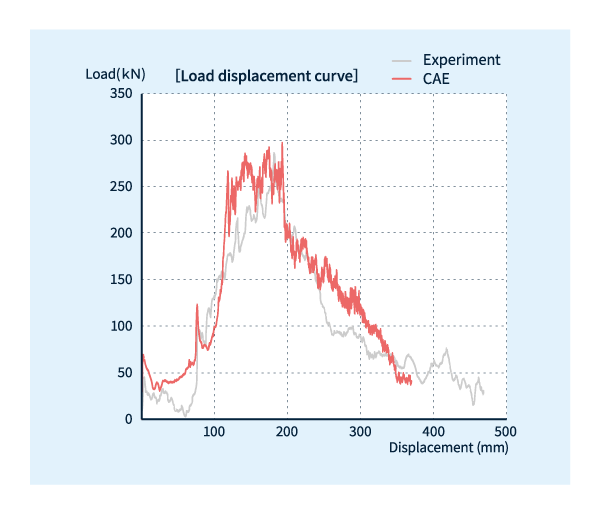

Impact analysis Details

Strain rate dependence of resins.

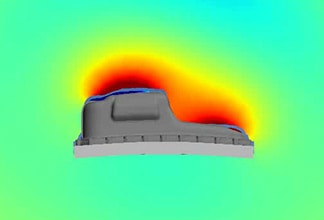

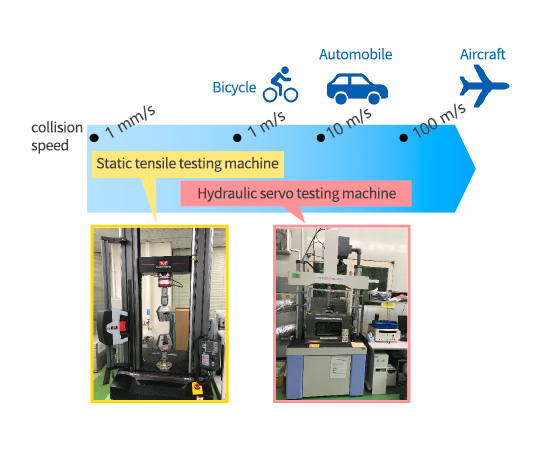

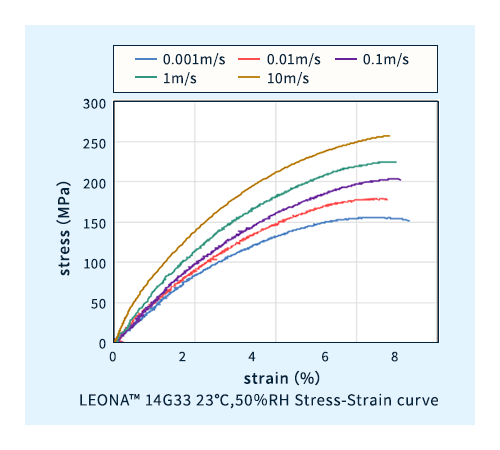

Resin has the property that its material properties change depending on the deformation speed, which is called strain rate dependency.

When the phenomenon to be predicted falls within the high speed range, the stress-strain relationship at high speeds is required. For this reason, a normal static tensile testing machine cannot be used, and a hydraulic servo testing machine is used.

However, high-speed tensile testing is extremely difficult, and even Asahi Kasei has data for only a limited number of materials.

If the phenomenon you want to predict becomes faster, you cannot express only by the normal resin characteristics (low-speed stress-strain curve).

Asahi Kasei’s unique material model

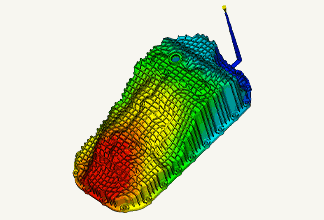

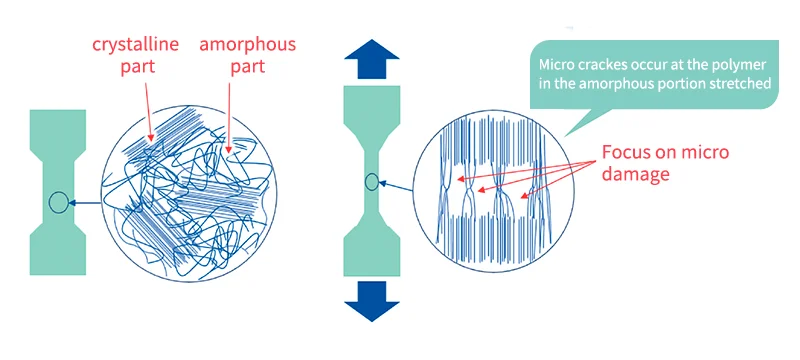

Crystalline resins, such as polyamide, contain crystalline and amorphous parts, as shown in the figure (left).

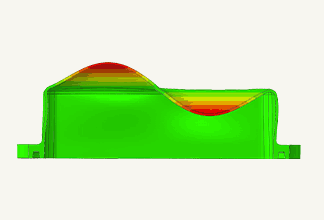

When a dumbbell-shaped test piece of unreinforced polyamide is pulled, necking occurs as shown in the figure (right), resulting in ductile fracture. This is a characteristic unique to resins, in which the polymer in the amorphous region is stretched, microscopic damage occurs, and fracture occurs at the boundary between the crystalline and amorphous regions.

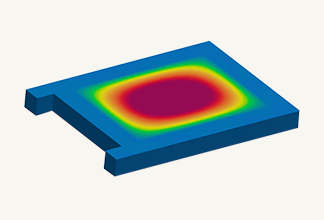

In order to predict the fracture mode and amount of energy absorbed at the time of fracture, our company and our group company, Asahi Kasei Engineering Corporation, have developed a material model that takes such microscopic damage into account and applied it to impact analysis.

We have developed a material model that considers such microscopic damage and applied it to impact analysis so that we can predict the failure mode and the amount of energy absorbed at the time of failure.

● If you are interested in the equations used in the material model, please refer to the literature.