“Asahi Kasei Europe Battery Project”

Interviews

For inquiries regarding SDS and various chemical substance investigations, please make your request through your purchasing route, such as via a trading company.

We appreciate your understanding and cooperation.

Download slides

2022.10.17

Technologies and Products

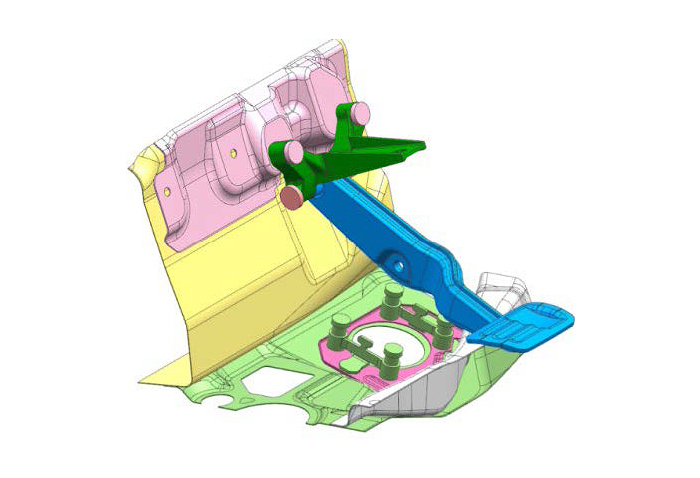

Asahi Kasei has in-house expertise in resin computer-aided engineering (CAE), a set of analytical techniques developed specifically for designing resin products. Today, CAE analysis technology for plastics is an extremely useful product development tool. In response to various requests from customers, such as the replacement of metal with plastic, we use CAE to study the concept, design the shape for plastic, perform various tests in the computer, predict the service life, and design the mold, such as optimizing the gate position, and propose these to the customer. The customer then builds a prototype based on this design and evaluates the product. This allows us to produce high performance products in a short period of time and at a low cost. By combining Asahi Kasei plastics with resin CAE analysis technology, we can provide customers with high value-added experience.

In this article, we will introduce the case study of a plastic brake pedal bracket for the MX-5, Mazda Motor Corporation, in which a significant weight reduction was achieved by using topology optimization analysis technology. (2018 Enlighten Award winning technology)

Click here to download the CAE Application Case Study

Please feel free to contact us with any questions about our products or technologies or to request samples.

We will introduce Asahi Kasei 's engineering plastic products and technologies in more detail.

We regularly deliver product and industry information to help you gather information.