Press Releases

For inquiries regarding SDS and various chemical substance investigations, please make your request through your purchasing route, such as via a trading company.

We appreciate your understanding and cooperation.

2023.11.14

Interviews

In 2022, we celebrated the 100th anniversary of the founding of Asahi Kasei—and immediately began working toward our next 100years with challenging initiatives to build sustainable societies and create new value.

Today we’ve asked two engineers—Shunta Kimura who has worked on the development of products such as non-woven fabrics and UD tape (uni-directional tape, a one-directional fiber-reinforced material), and Yuki Mori, an expert technologist who has been contributing to polyamide development at Asahi Kasei for many years—to tell us about UD tape and how Asahi Kasei came to develop it.

Kimura Shunta (left) and Mori Yuki (right) involved in the development of UD tape

Kimura Shunta (left) and Mori Yuki (right) involved in the development of UD tape

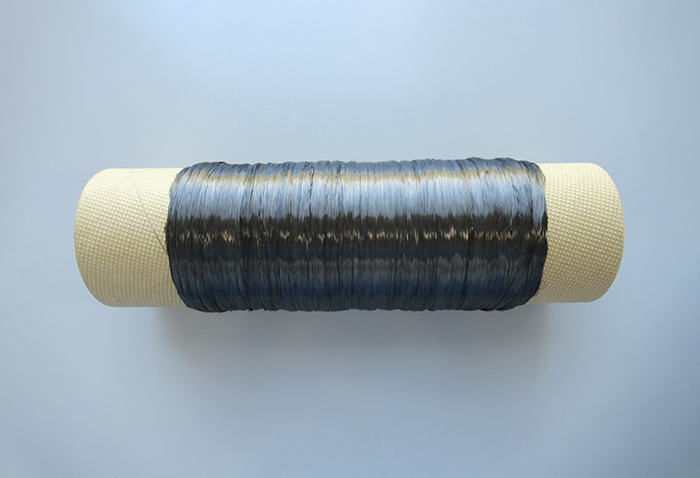

Mori: UD tape ( “uni-directional tape,” a one-directional fiber-reinforced material), we’ve developed at Asahi Kasei is a fiber-reinforced materialmade by impregnating carbon fibers with polyamide resin (PA, nylon), yielding a substance in which carbon fibers account for approximately half the volume. The polyamide resin used for this impregnation is based on the polymer technology used to produce Asahi Kasei’s LEONA™ polyamide resins. The key feature of UD tape is that its reinforcing fibers exhibit a one-directional contiguity structure, allowing the fibers to maximize their reinforcing effect.

UD tape: a carbon-fiber-reinforced polyamide resin

UD tape: a carbon-fiber-reinforced polyamide resin

Mori: Our UD tape offers three crucial advantages: dense impregnation of polyamide resin among carbon fibers, strong adhesion, and minimal variation in physical properties due to water absorption. First, the specialized polyamide resin we use has extremely low viscosity when heated to its molten state, allowing it to flow freely through gaps between carbon fibers to achieve deep penetration—and dense impregnation. This yields a material in which carbon fibers and resin are packed densely together in a highly monolithic structure, maximizing the reinforcing impact of the carbon fibers.If the impregnation is insufficiently dense, the material winds up incorporating a large number of empty regions, called voids. Voids degrade material properties by serving as origin sites for material failure when molded products made from void-rich UD tape are subjected to loading.

We have also improved the adhesive properties by controlling the melting and solidification behavior of our specialized polyamide resin. The polyamide resin used in UD tape exhibits a property known as thermoplasticity, which means it can be melted by heating within a mold, then solidified by cooling to yield molded products. When molded products are manufactured by stacking multiple layers of UD tape in a heat press, the layers of UD tape adhere to each other quite well. Similarly, for injection-molding processes involving materials heated to the molten state on UD tape, we observe good adhesion between the UD tape and the injection-molded materials. Finally, typical polyamide resins have a problem that their material properties are degraded by water absorption, but this is one area in which our LEONA™ polymer technology has been put to good use.

Kimura: Components formed from UD tape , when used in combination with injection-molding techniques, allow us to produce injection-molded components that are both strength-reinforced and shaped like final products. For example, by inserting a pre-formed UD-tape ring into an injection mold prior to the injection-molding process, we can fabricate complex components with inlet regions reinforced in strength by the presence of the ring.

Ring made with UD tape

Ring made with UD tape

Injection-molded component with inlet reinforced by UD-tape ring

Injection-molded component with inlet reinforced by UD-tape ring

For components made from UD tape itself, one common molding method is "heat-press molding": Multiple copies of a desired shape are cut out from sheets of raw material, layered atop one another in a mold, heated above the melting temperature of UD tape, and then cooled under applied pressure, fusing the tape layers into a monolithic molded component. Another approach, which exploits one of the unique strengths of UD tape—the contiguity of the carbon fibers—is to cut material sheets into rectangular fragments, with side lengths of perhaps a few centimeters, and then randomly pack these fragments into a mold for heat-press molding. This technique can be used to produce products with complicated 3-dimensional shapes.

Rectangular fragments, with sides a few centimeters in length, forming a sheet-shaped UD Tape

Rectangular fragments, with sides a few centimeters in length, forming a sheet-shaped UD Tape

Component formed by heat-press molding of multiple layers of sheet-shaped UD Tape (left picture)

Component formed by heat-press molding of multiple layers of sheet-shaped UD Tape (left picture)

Another approach is "lay-up molding", in which UD tape is melted by laser heating as it is being affixed to a component. This allows the UD tape to be applied only in regions and in directions where it is necessary, ensuring efficient use of material resources. Finally, the method known as "winding" involves wrapping UD tape around a rotating axis while heating to melt the tape. This allows fabrication of pipes, rings, and other shapes that are difficult to achieve via press molding.

High-strength pipe made with UD-Tape

High-strength pipe made with UD-Tape

Mori: I’ll need to start quite a ways back. Asahi Kasei had been making various types of polyamides by blending different varieties of monomers with a polyamide-66 base. In the late 1990s, this led to the creation of the LEONA™ 90G series, which was definitely one of our hit product lines. These resins were based on quasi-aromatic polyamide 66 polymers, which we made by blending polyamide 66 with aromatic ingredients, and they allowed us to develop injection-molding grades reinforced by blending in high concentrations of glass fibers and other reinforcers.

At the time, I was in charge of technical support for both domestic and foreign clients, with the goal of promoting sales of 90G-series products. And, sure enough, we were growing sales pretty steadily, but eventually we started to hear cost complaints from customers in places far from Japan, like the U.S. and Europe. The reason was that the production facility at which we blended the base polymers was located in Nobeoka, in Japan’s Miyazaki Prefecture, and we were shipping the products all the way from there to our overseas customers. So that motivated us to design and implement a local-production scheme to minimize costs. Later, in 2018—some 20 years after the creation of the LEONA™ 90G series—there emerged a new type of quasi-aromatic polyamide polymer with an even higher ratio of aromatic components, which forms the basis of the LEONA™ SG series that we are currently rolling out to the market.

Mori: As it turns out, the idea of combining composite materials with injection molding was something we had already been considering for our 2017 research plan. Then, in 2019, I was chatting with a good friend who heads development for a German company, and my friend said “Actually, we’ve been trying to do something like this……” and showed me a video describing applications of UD tape. That was really the impetus that kickstarted our development efforts. Because, when I saw that movie, something clicked, and it dawned on me that combining UD tape with Asahi Kasei’s injection-molding materials would furnish a timely solution for customers seeking to replace metallic components with resin-based alternatives. This approach would not only eliminate lengthy material-development cycles, but would also increase the added value of our injection-molding materials—thereby promoting sales. It also represented a shift away from our conventional strategy of selling things, such as developing new materials in response to customer requests, and towards a new spirit of selling solutions, such as helping customers replace metallic components with resin-based alternatives. Personally, I find this more active, more creative type of work to be much more interesting—and much more rewarding.

Mori: Yes, that’s true. The carbon-fiber producers were the first to get into the game, and we didn’t join until quite a while later. But I figured that, if Asahi Kasei didn’t take on new challenges like this, we would never be able to grow significantly in the future. That’s why I, as the guy in charge of development, went up to the management suite and tried to get the ball rolling: We can’t just keep asking our customers for instructions on what to do—pretty soon we won’t be able to stand on our own two feet! We need to start tackling bigger challenges! And to our engineers I said "Hey, let’s get together and develop some more interesting stuff! "

Kimura: I’ve been reporting to Mori-san since 2019, and the development of UD tape is something we’ve worked on together. But, before that, I had been working with recycled carbon fiber (rCF) ever since I joined Asahi Kasei in 2017. One of my projects was to develop applications for injection-molding material grades reinforced by rCF, which offers excellent specific strength and specific rigidity. As a side project, to facilitate shifting the portfolio of the engineering-plastic business away from injection molding, I was working on developing non-woven fabrics by combining LEONA™ fibers with long-fiber rCF, which features fiber lengths on the order of a few centimeters

The molding techniques and evaluation procedures required for hybrid materials of this type are totally different from those used for injection-molding materials, and I was trying to learn everything I could—scouring the academic literature, attending research seminars and conferences, and even sitting with equipment operators on factory floors trying to optimize process conditions. It was pretty exhausting! But, looking back on it now, I wouldn’t trade that experience for the world—the things I learned during that process, and the connections I made with molding manufacturers and research institutions, are still paying dividends to this day for our development of UD tape.

Mori: At present, our development schedule is based on plans to bring UD tape to market in 2025 or 2026. We’re hoping to expand our outlook to encompass electric and electronic devices, sports and leisure products, and construction materials—and, eventually, automotive and aerospace components as well. For example, in the sporting domain we think there will be applications to products like golf clubs and athletic shoes.

I also think that finding new corporate partners to collaborate with us will be crucial going forward—particularly companies, whether large or small, involved in plastic molding. People may have an image of Asahi Kasei as a big, mature, established company—but we think of ourselves as a scrappy startup. Above all else, my goal is to use UD tape to build compelling business propositions with companies seeking to do interesting things and make a mark on the world.

And I look forward to Kimura-san’s generation tackling the new challenges that will advance Asahi Kasei as a company—and power it forward through its next 100 years.

Please contact us to ask any questions, discuss any concerns, and request samples regarding UD Tape.

Please feel free to contact us with any questions about our products or technologies or to request samples.

We will introduce Asahi Kasei 's engineering plastic products and technologies in more detail.

We regularly deliver product and industry information to help you gather information.