NEW

業界コラム

資料ダウンロード

2025.06.30

NEW

プレスリリース

2025.06.23

NEW

技術・製品紹介

2025.07.04

インタビュー

2025.03.14

展示会情報

資料ダウンロード

2025.02.19

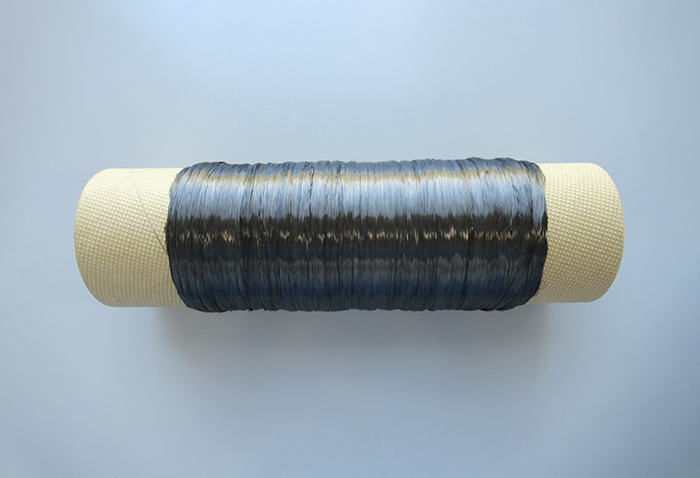

サンフォース®

|UDテープ

NEW

ウェビナー

ウェビナー申込み

2025.06.24

NEW

技術・製品紹介

2025.06.17

技術・製品紹介

2025.02.07

CNF強化熱可塑性樹脂

展示会情報

2025.02.13

変性PPE樹脂 ザイロン™

|POM樹脂 テナック™

|PA樹脂 レオナ™

|Thermylon®

|Thermylene®

プレスリリース

2025.03.18

変性PPE樹脂 ザイロン™

|POM樹脂 テナック™

|PA樹脂 レオナ™

|Thermylon®

|Thermylene®

技術・製品紹介

2025.01.20

インタビュー

2025.01.16

変性PPE樹脂 ザイロン™

技術・製品紹介

2024.11.13

サンフォース®

展示会情報

資料ダウンロード

2024.11.01

変性PPE樹脂 ザイロン™

|POM樹脂 テナック™

|PA樹脂 レオナ™

展示会情報

資料ダウンロード

2024.10.31

POM樹脂 テナック™

技術・製品紹介

2024.10.29

展示会情報

資料ダウンロード

2024.09.24

UDテープ

|PA樹脂 レオナ™

技術・製品紹介

2024.09.10

技術・製品紹介

2024.07.16

技術・製品紹介

2024.07.10

技術・製品紹介

2024.05.22

プレスリリース

展示会情報

2024.05.20

変性PPE樹脂 ザイロン™

業界コラム

2024.04.18

インタビュー

2024.02.13

プレスリリース

2024.02.01

プレスリリース

2023.12.15

PA樹脂 レオナ™

インタビュー

2023.11.14

技術・製品紹介

2023.11.10

プレスリリース

2023.11.02

プレスリリース

展示会情報

2023.12.04

プレスリリース

展示会情報

2023.10.10

プレスリリース

2023.09.06

業界コラム

2023.08.21

業界コラム

2023.07.07

技術・製品紹介

2023.06.23

展示会情報

資料ダウンロード

2023.06.30

プレスリリース

2023.06.08

プレスリリース

2023.05.16

プレスリリース

2023.06.01

展示会情報

2023.05.29

業界コラム

2023.05.19

プレスリリース

展示会情報

2023.05.12

業界コラム

2023.04.07

プレスリリース

2023.04.27

業界コラム

2023.03.09

展示会情報

2023.05.22

業界コラム

2023.02.01

業界コラム

2022.11.30

プレスリリース

展示会情報

2022.11.30

プレスリリース

2022.11.15

プレスリリース

2022.12.14

インタビュー

2022.11.14

業界コラム

2022.10.27

業界コラム

2022.10.27

プレスリリース

2022.10.18

プレスリリース

2022.10.11

プレスリリース

2022.10.07

技術・製品紹介

2022.10.11

業界コラム

2022.08.31

業界コラム

2022.08.31

プレスリリース

2022.08.23

プレスリリース

展示会情報

2022.08.08

技術・製品紹介

2022.08.02

業界コラム

2022.08.01

業界コラム

2022.08.01

業界コラム

2022.07.01

業界コラム

2022.07.01

業界コラム

2022.06.09

業界コラム

2022.06.09

業界コラム

2022.05.18

業界コラム

2022.05.18

プレスリリース

2022.04.20

プレスリリース

2019.05.22

プレスリリース

2018.11.09

プレスリリース

2022.04.19

技術・製品紹介

資料ダウンロード

2022.03.28

プレスリリース

2022.03.16

技術・製品紹介

2022.03.15

業界コラム

2022.03.02

技術・製品紹介

2022.02.14

プレスリリース

2021.12.17

プレスリリース

技術・製品紹介

2022.12.06

技術・製品紹介

資料ダウンロード

2021.11.10

技術・製品紹介

2021.10.15

技術・製品紹介

資料ダウンロード

2021.09.27

技術・製品紹介

資料ダウンロード

2021.07.26

技術・製品紹介

資料ダウンロード

2021.06.22

プレスリリース

2021.06.15

インタビュー

2021.06.02

インタビュー

2021.05.20

技術・製品紹介

資料ダウンロード

2022.11.22

インタビュー

2021.03.24

技術・製品紹介

2021.03.29

技術・製品紹介

2021.03.29